Wafer suction device and method for parallel device

A wafer and equipment technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of not being able to let go of the wafer, and achieve the effects of easy operation, reducing fragmentation rate, and improving equipment utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

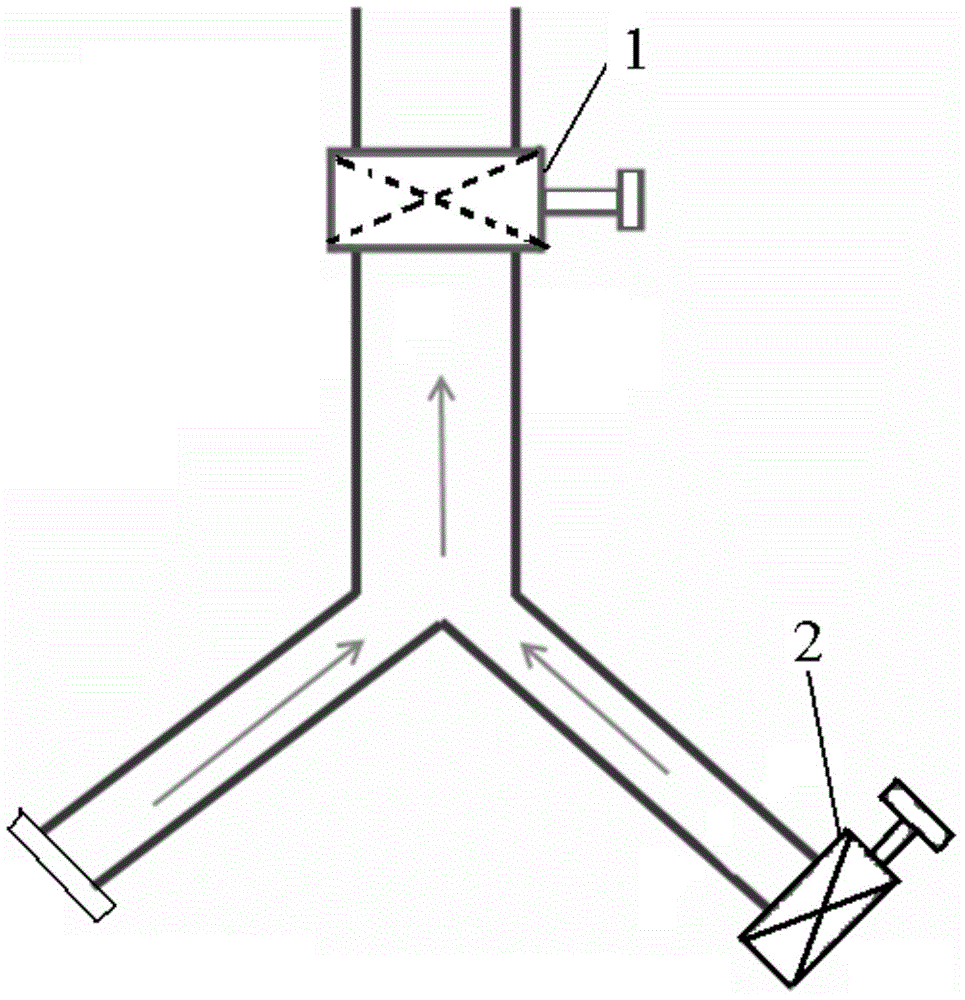

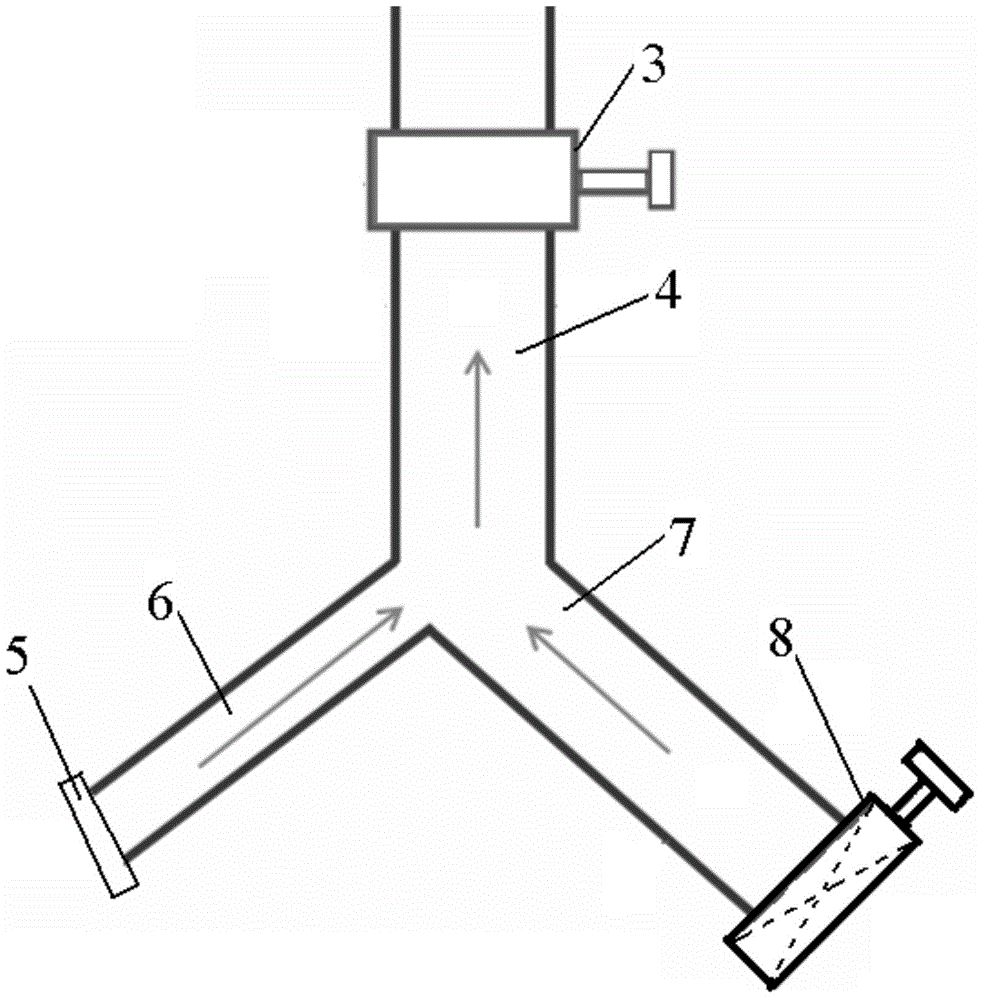

[0020] Such as figure 2 As shown, the present invention provides an adsorption wafer device for parallel equipment, including: factory vacuum pipeline 4, equipment vacuum pipeline 7, vacuum channel 6 and suction cup 5, suction cup 5 is arranged at one end of vacuum channel 6, factory vacuum pipeline 4. The equipment vacuum pipeline 7 is in communication with the vacuum channel 6 , and the pipeline diameter of the equipment vacuum pipeline 7 is greater than or equal to the pipeline diameter of the plant vacuum pipeline 4 .

[0021] In this embodiment, the purpose of changing the diameter of the vacuum pipeline of the equipment and controlling the sucker to pick up and release the wafer.

[0022] In a preferred embodiment, it further includes: a first vacuum valve 3 , and the first vacuum valve ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap