Intermediate reflection structure in thin film solar cells

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as being unsuitable and not conducive to good contact of devices, and achieve the effects of easy production, good electrical contact, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

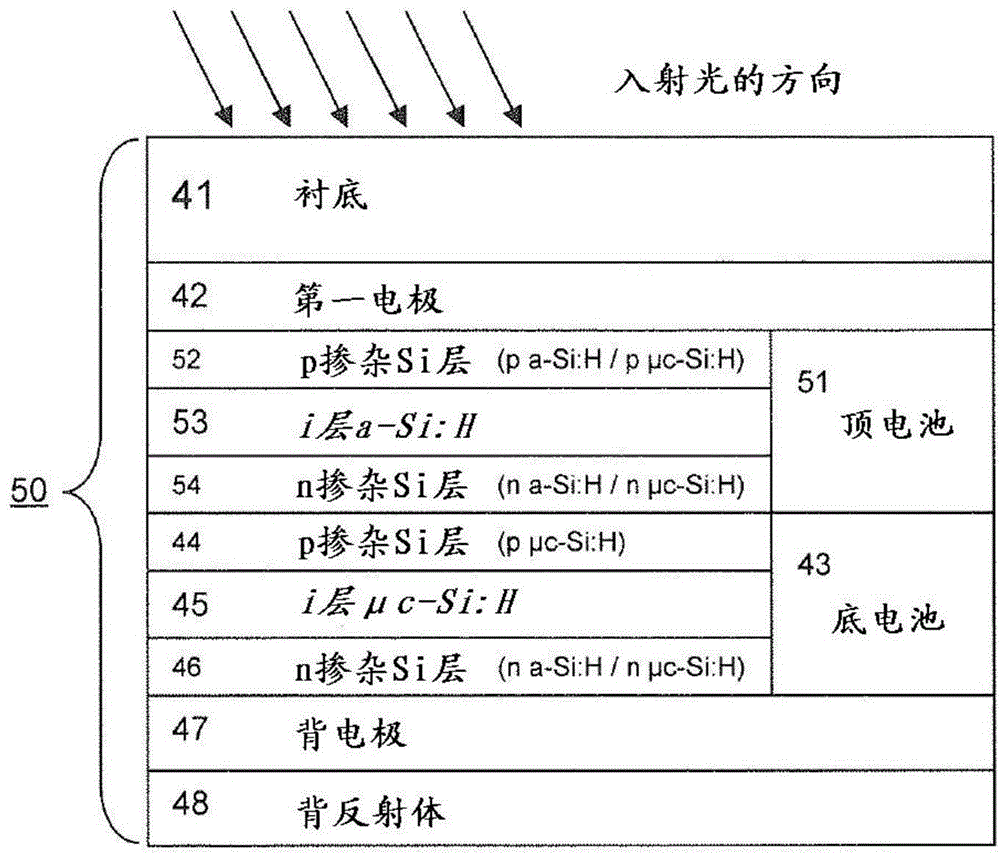

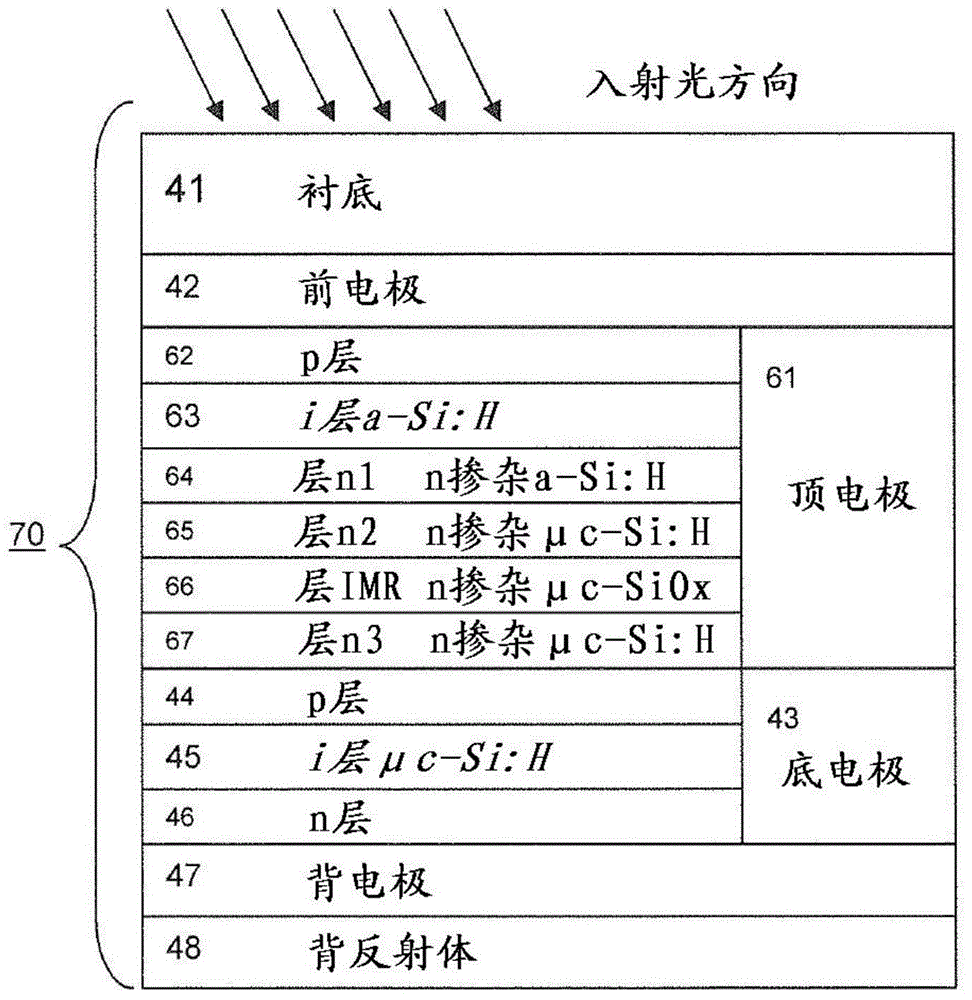

[0082] The focus of the present invention is as image 3 The design and characteristics of the n-layer of the amorphous top cell 61 of the amorphous micromorph tandem cell 70 are depicted. However, it can be applied to any thin film silicon multi-junction cell of this type. The amorphous top cell here means the first cell on the light incident side characterized by an amorphous i-layer 63 (which may also be graded or multiple i-layers as long as it is amorphous).

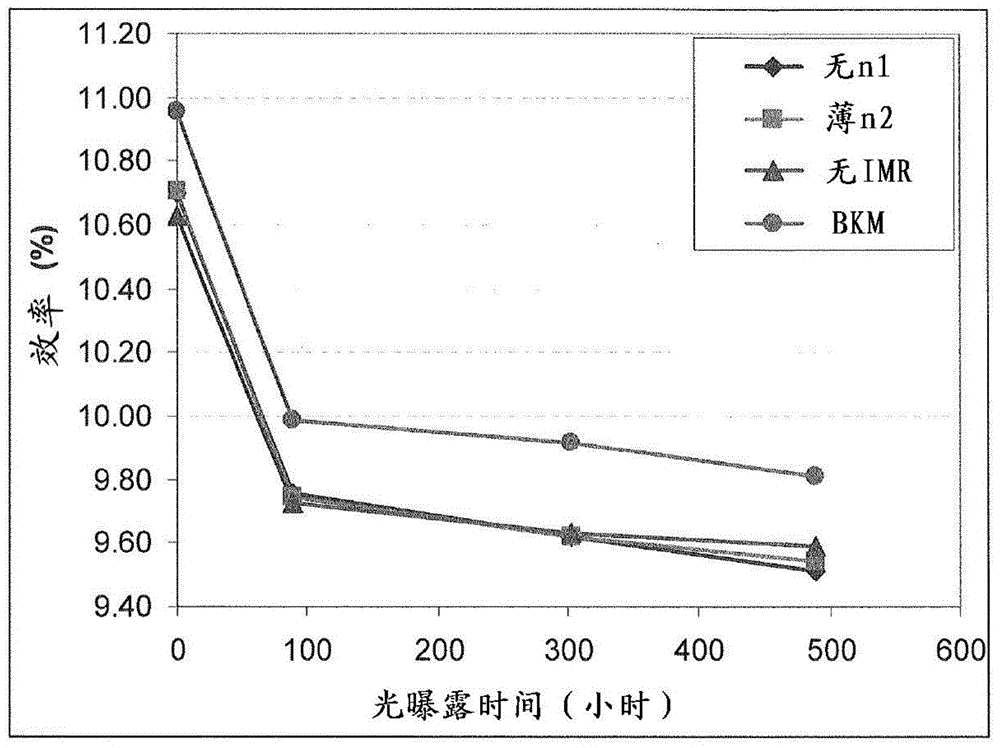

[0083] The present invention proposes to modify the prior art n-layer 54 into a multilayer structure 64-67. Two n-layer structures were found to be the optimal solution with regard to the highest initial and stable amorphous microcrystalline module power (BKM). The layer deposition sequence described below starts after the deposition of the amorphous i layer 63 . Variations 3A and 3B are combined with additional steps for forming the two BKMs respectively:

[0084] 1. Deposit an n-layer (n1, 64) of amorphous silicon

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap