Methanol fuel gasification stove

A technology of methanol fuel and gasification stove, which is applied in the direction of heating fuel, liquid heating fuel, household stove/stove, etc. It can solve the problems of insufficient combustion and complicated equipment, and avoid insufficient combustion, manufacturing cost and combustion cost The effect of low, obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

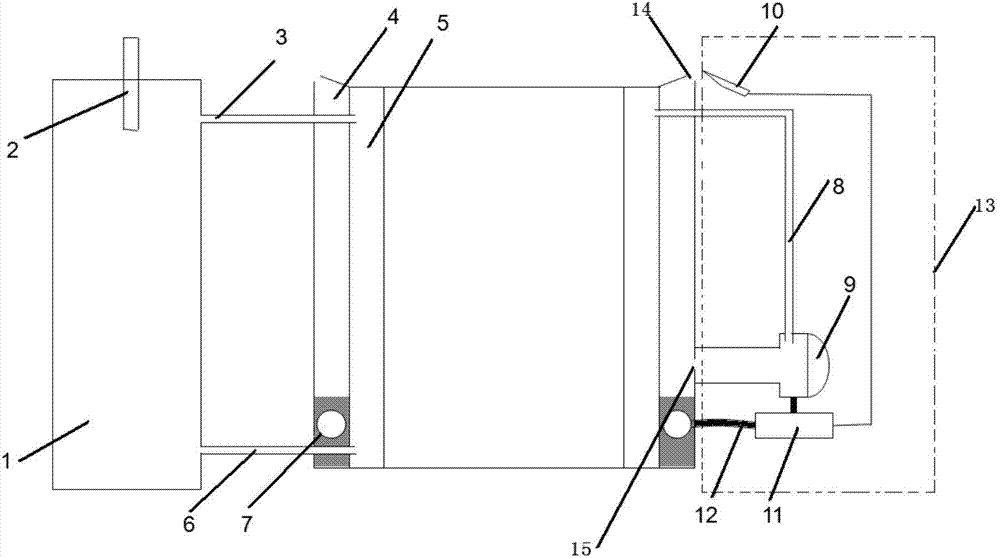

[0024] Please refer to figure 1 , the methanol fuel gasification stove in this embodiment includes: an ignition device 13, a heating device 7, a gas distribution chamber 4, a gas chamber 5, a fuel pipe 6, a pressurizing pipe 3, a gas supply pipe 8 and a methanol storage device 1, The methanol storage device 1 communicates with the gas chamber 5 through the fuel pipe 6, and the fuel pipe 6 is arranged at the lower part of the methanol storage device 1 for dissolving the liquid methanol stored in the methanol storage device 1. The fuel is introduced into the gas generating chamber 5; the liquid methanol fuel in the methanol storage device 1 enters the gas generating chamber 5 through the fuel pipe 6 for preheating instead of d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap