Chain tensioner

A tensioner and chain technology, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problems of motor damage, easy deformation and breakage of the chain, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

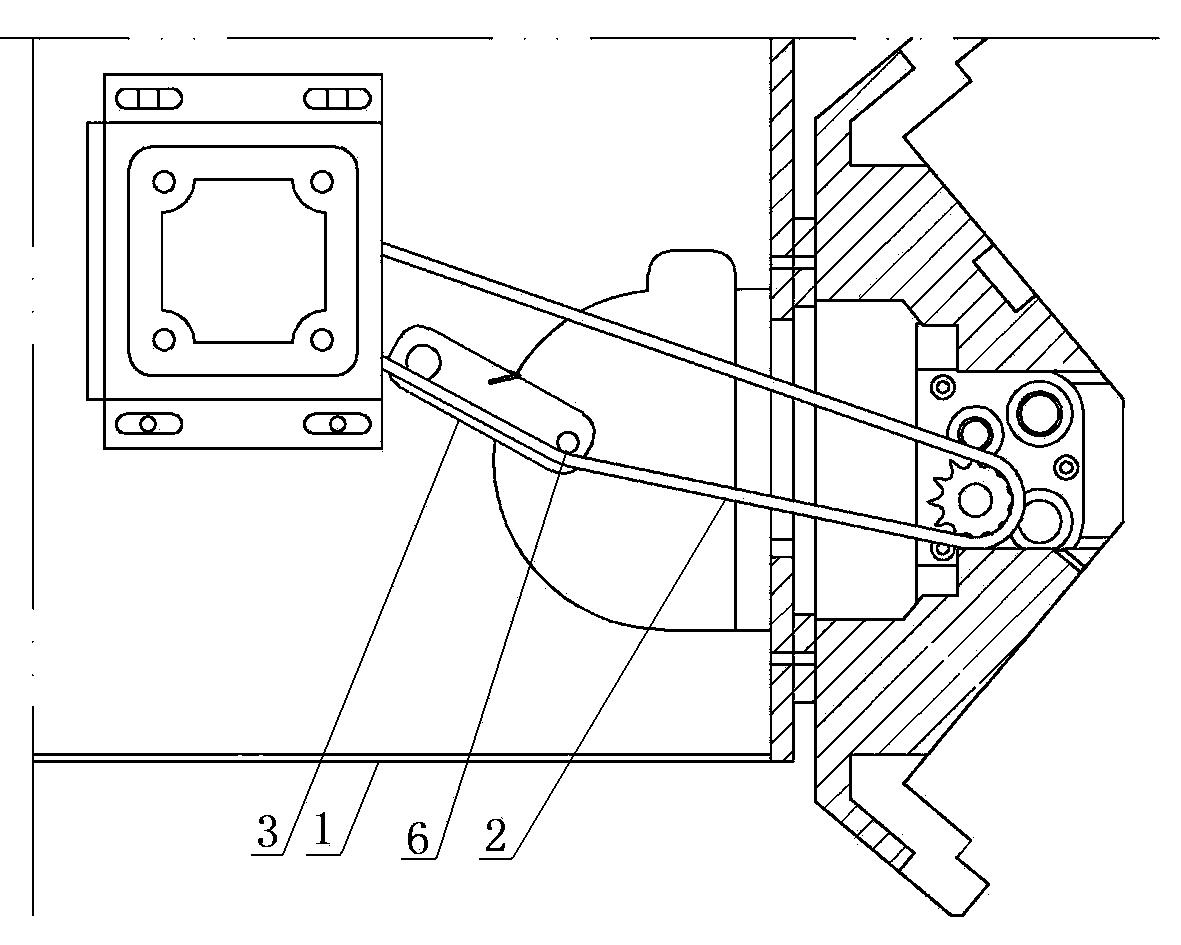

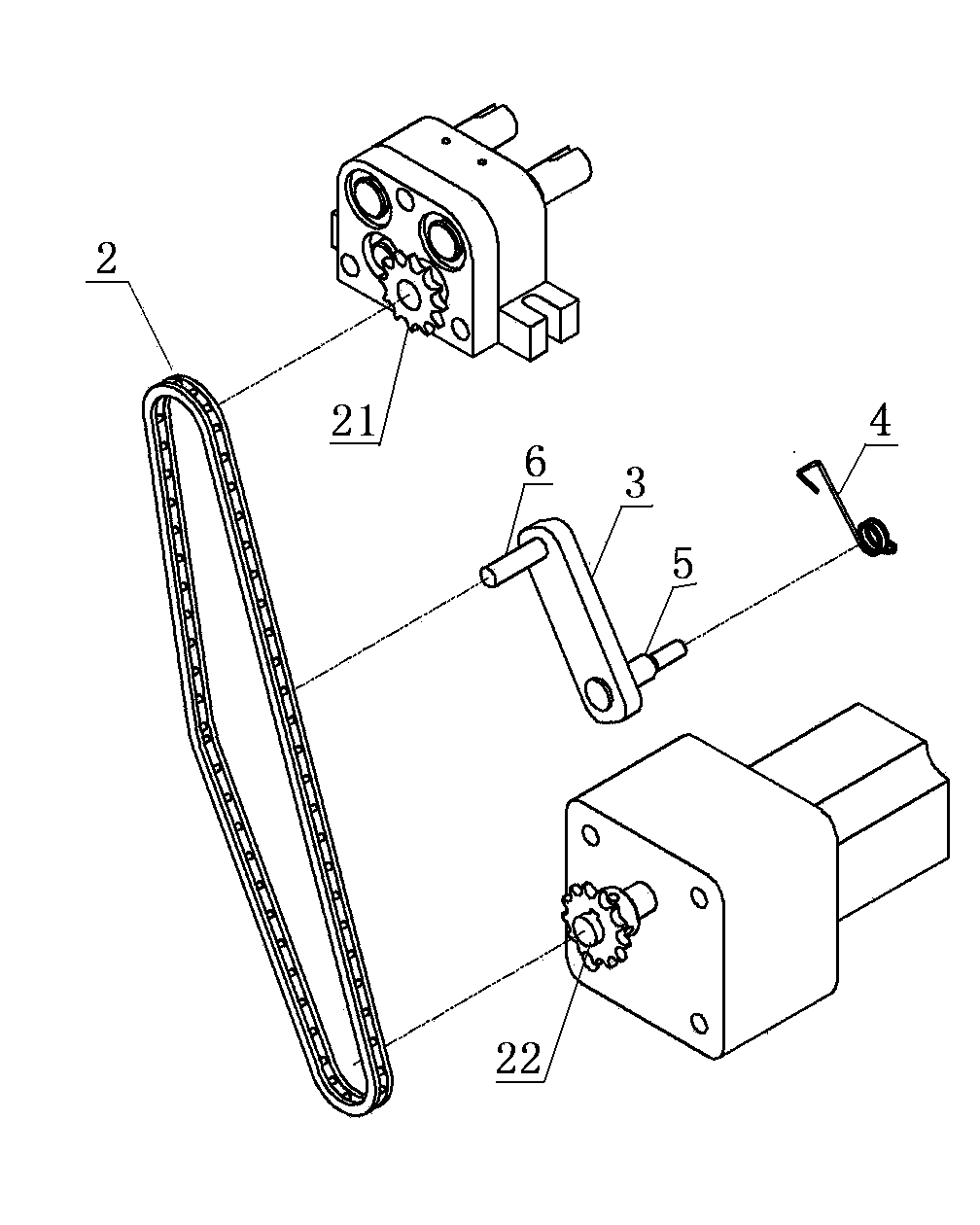

[0013] Such as figure 1 with figure 2 As shown, the chain tensioner is installed on the machine base 1 and used to adjust the tension of the chain 2. One end of the chain is sleeved on the rotating shaft 21 of the roller, and the other end is sleeved on the power output shaft 22 of the motor.

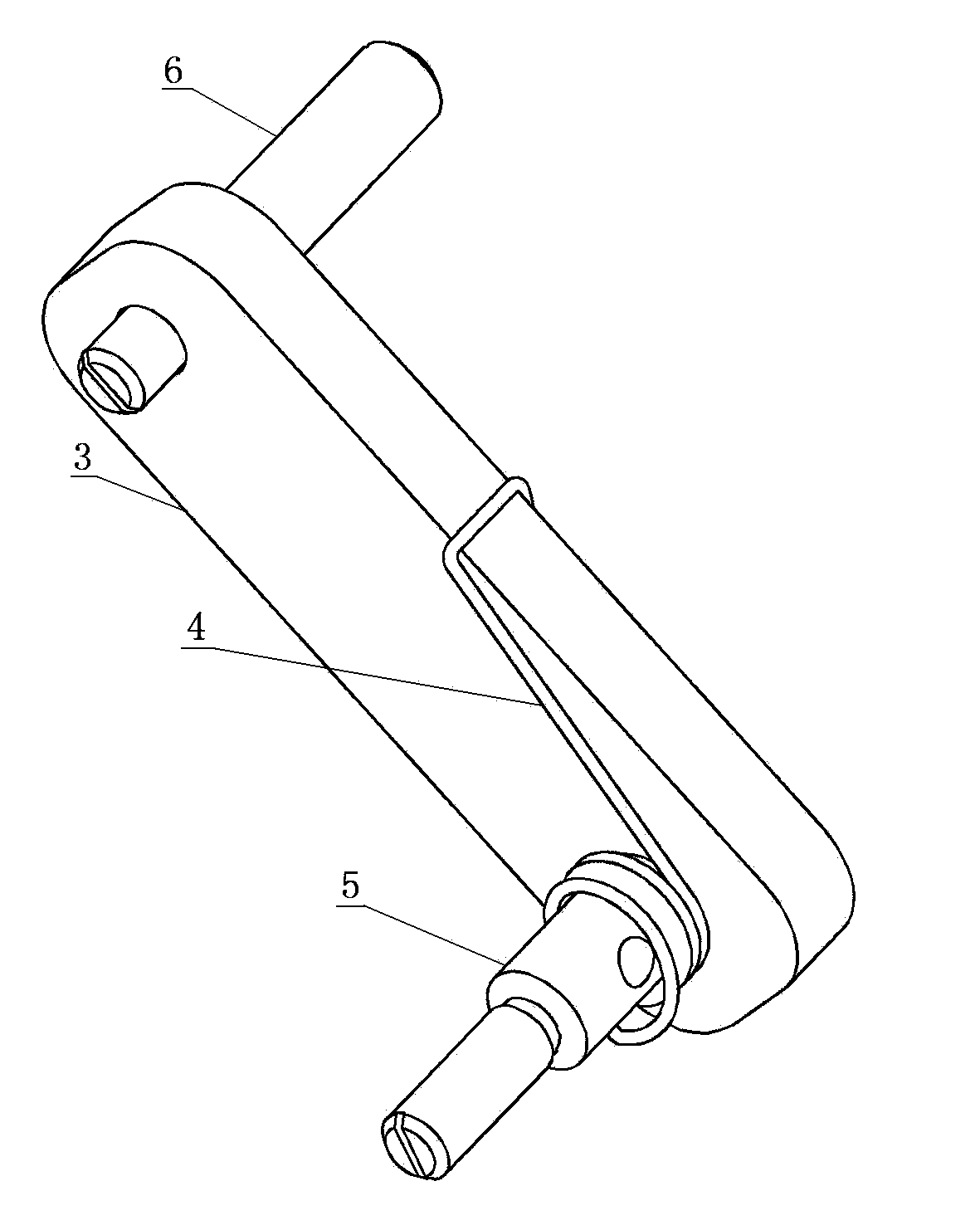

[0014] Such as image 3 As shown, the chain tensioner is mainly composed of a pendulum wall 3, a compression spring 4, a rotating shaft 5, and a compression shaft 6. The pendulum wall 3 is elongated, and both ends of the pendulum wall 3 in the length direction are semicircular shape.

[0015] The positions of the rotating shaft 5 and the pressing shaft 6 are preferably set on the center of the two semicircular ends of the pendulum wall.

[0016] The rotating shaft 5 and the pressing shaft 6 are respectively located on two opposite end surfaces of the pendulum wall 3 and are perpendicular to the pendulum wall. In order to make the pendulum wall tighter on the chain better, the end faces of the p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap