Heat-preservation steel cylinder

A steel cylinder and heat preservation technology, applied in the field of pressure vessels, can solve problems such as poor heat preservation performance, and achieve the effects of good heat preservation effect, simple structure and easy manufacture.

Inactive Publication Date: 2015-03-18

吴涛

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the disadvantages of poor thermal insulation performance of existing steel cylinders, the invention provides a thermal insulation steel cylinder, which has a simple structure and is easy to manufacture

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

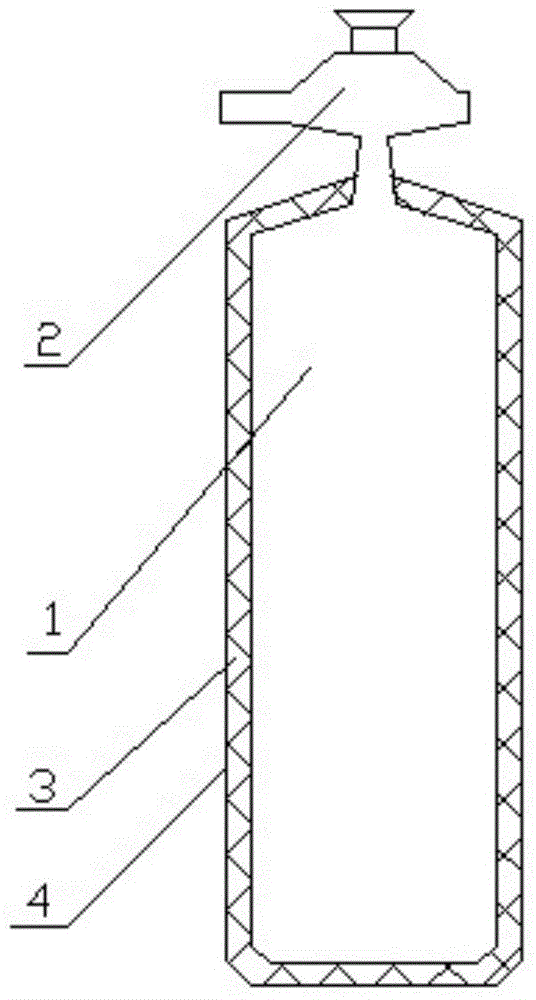

[0009] in figure 1 Among them, the insulated steel cylinder includes a bottle body 1 and a valve 2 on the bottle body 1. A polyurethane insulation layer 3 is provided on the outside of the bottle body 1, and the outer polyurethane insulation layer 3 is a shell layer 4 composed of plastic materials.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention provides a heat-preservation steel cylinder. A polyurethane insulation layer is arranged outside a cylinder body and a shell layer made of a plastic material is arranged outside the polyurethane insulation layer. By virtue of the polyurethane insulation layer, the steel cylinder has an excellent heat preservation effect; in addition, the steel cylinder is simple in structure and easy to manufacture.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner 吴涛

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap