Composting fermentation method for organic fertilizer

A fermentation method and technology of organic fertilizer, applied in the field of bio-organic fertilizer composting and fermentation, can solve the problems of slow fertilizer efficiency and reduce the agricultural value of compost, and achieve the effects of accelerating the degradation of substances, promoting the reproduction speed, and enhancing the degradation activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Using chicken manure as the main raw material, the fresh chicken manure is naturally dehydrated to a moisture content of 45%. Then add rice husk and humic acid according to the mass ratio of dehydrated chicken manure, rice husk and humic acid at 70:20:10. Add KH according to 0.5% of the weight of dehydrated chicken manure 2 PO 4 as a P source. According to 1% of the total weight of the material, a composite fermentation bacterial agent is added, and the composite fermentation bacterial agent is a mixed bacterial agent prepared by a mass ratio of Bacillus licheniformis and Bacillus subtilis at a mass ratio of 1:1.

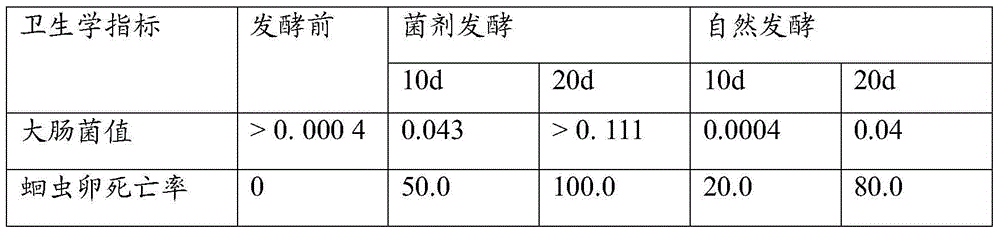

[0016] The composting time of chicken manure compost treated with compound fermentation bacteria agent to reach the harmless target is generally about 20 days, while the time for natural fermentation to reach the same target usually takes about 60 days. The growth and reproduction of microorganisms accelerates the degradation of substances in the fermented ma

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap