Method for removing arsenic and antimony in water body by using active base metal replacement

A base metal and active technology, applied in the field of active base metal replacement to remove arsenic and antimony in water, to achieve the effect of high efficiency, easy implementation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

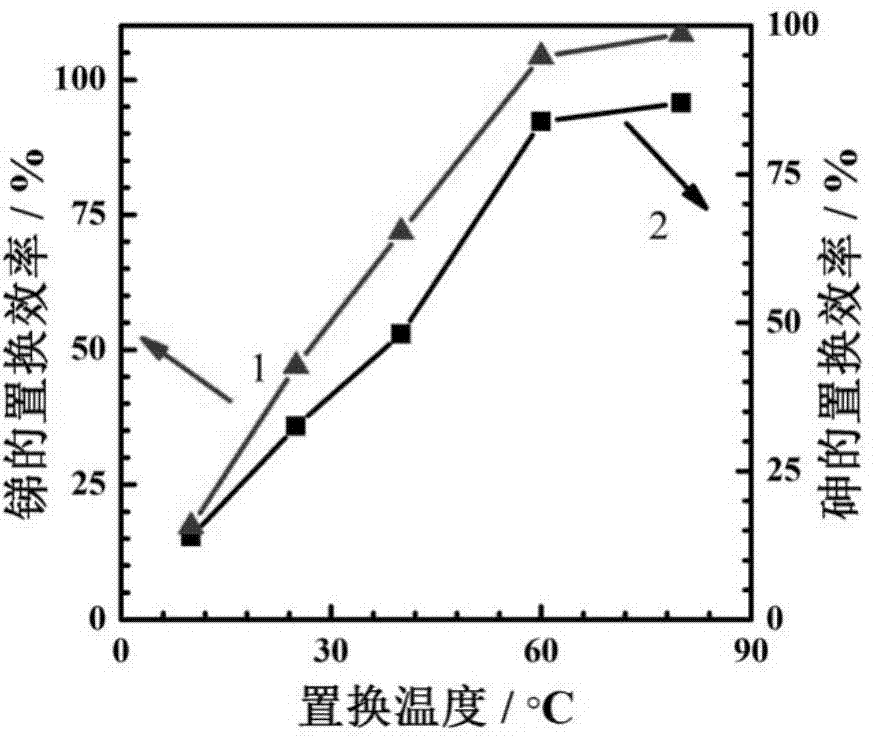

Image

Examples

Embodiment 1

[0018] Take 200mL As(III) content is 3.6gL -1 , Sb(III) content is 5.8gL -1 The silver slag leaching solution was placed in the reactor, the pH of the solution was adjusted to 0 with hydrochloric acid, 10g of iron powder (60 mesh) and 0.5g of ammonium citrate were added, the stirring speed was 400r / min, the reaction temperature was 40°C, and the replacement time was 10~120min.

[0019] Replacement efficiency was used to evaluate the replacement and removal effect of iron powder on arsenic and antimony in water.

[0020] Table 1 Experimental results of different replacement times

[0021] time / min

Embodiment 2

[0023] Take 200mL As(III) content is 3.6gL -1 , Sb(III) content is 5.8gL -1 The silver slag leaching solution is placed in the reactor, the pH of the solution is adjusted to 0 with hydrochloric acid, 10g of zinc powder (200 mesh) and 0.5g of ammonium citrate are added, the stirring speed is 400r / min, the reaction temperature is 40°C, and the replacement time is 10~120min.

[0024] Replacement efficiency was used to evaluate the replacement and removal effect of zinc powder on arsenic and antimony in water.

[0025] Table 2 Experimental results of different replacement times

[0026] time / min

[0027] 120

Embodiment 3

[0029] Take 200mL As(III) content is 8.2gL -1 , Sb(III) content is 13.8gL -1 The silver slag leaching solution is placed in the reactor, the pH of the solution is adjusted to 0 with hydrochloric acid, 10g of zinc powder (400 mesh) and 0.5g of ammonium citrate are added, the stirring speed is 400r / min, the reaction temperature is 40°C, and the replacement time is 10~120min.

[0030] Replacement efficiency was used to evaluate the replacement and removal effect of copper powder on arsenic and antimony in water.

[0031] Table 3 Experimental results of different replacement times

[0032] time / min

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap