Spray-free PC/ABS composite material with high gloss and high impact resistance and preparation method of spray-free PC/ABS composite material

A composite material, spray-free technology, applied in the field of PC/ABS composite materials, can solve the problems of material performance impact, increase the cost of parts, contrary to environmental protection and low carbon, and achieve the effect of high fluidity and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

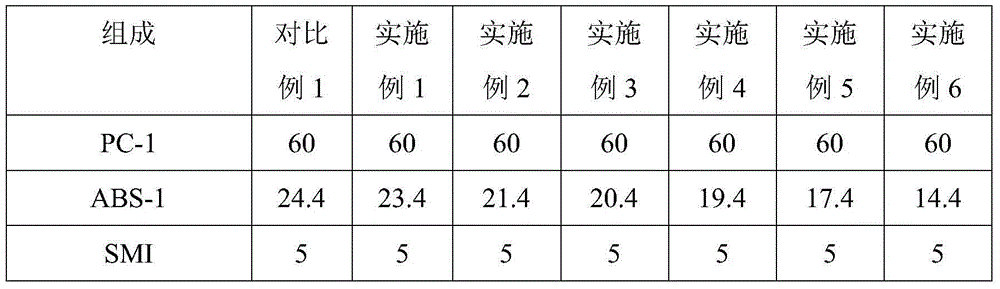

[0032] Comparative Example 1 and Examples 1-6:

[0033] The dried PC-1, ABS-1, SMI, MBS, non-spraying high-gloss masterbatch and antioxidant are mixed uniformly according to the composition ratio in Table 1, and then passed through a twin-screw extruder (screw diameter 35mm, length to diameter ratio L / D=36) In the main barrel, the main barrel has nine sections to control the temperature (from the feeding port to the machine head outlet) as 200℃, 230℃, 255℃, 255℃, 255℃, 255℃, 255℃, 255℃, 240℃ , The twin-screw speed is 300 rpm, and the extruded material is cooled in a water tank and then pelletized to obtain the product. The above products were dried in a blast oven at 95°C for 5 hours, and then injected into a standard sample and a standard light plate (150*100*3.2mm) by a plastic injection molding machine, and the injection temperature was 250°C. The molded sample and light plate are immediately placed in a glass desiccator and placed at room temperature for at least 24 hours fo

Example

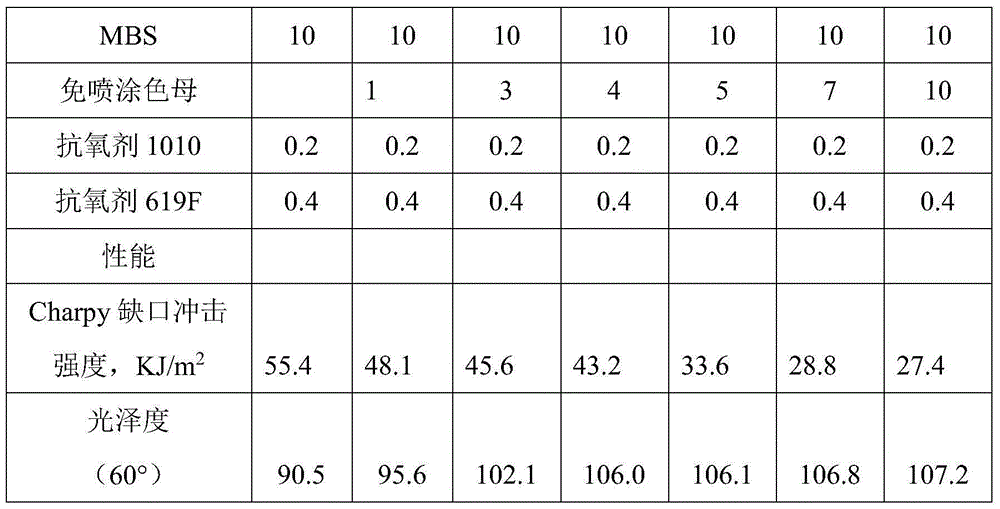

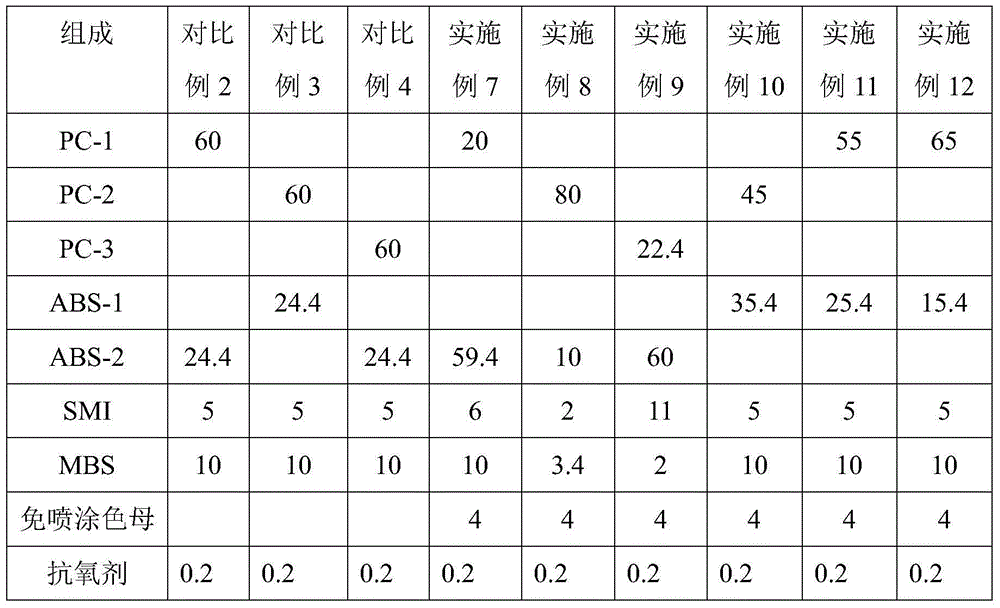

[0038] Comparative Examples 2-4 and Examples 7-12. According to the processing technology of Examples 1-6, PCs with different molecular weights and ABS with different preparation methods were used respectively, and the above-mentioned experiments were used to optimize the toughness and gloss without spraying. For the content of high-gloss color masterbatch, a PC / ABS resin mixture was prepared according to the composition and ratio in Table 2. The performance test and gloss are shown in Table 2.

[0039] Table 2 Composition and performance of PC / ABS composition

[0040]

[0041]

[0042] From the performance test results of the above comparative examples and examples, it can be seen that the use of different molecular weight PCs (PC-1,2,3) and ABS with different synthesis methods can produce spray-free, high-gloss, high-impact PC / ABS composites Materials, using different molecular weight PCs and different synthesis methods of ABS can produce spray-free, high-gloss, high-impact PC

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap