Weight control method for electrophoretic deposition ceramic green body

An electrophoretic deposition and weight control technology, applied in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of difficult control of the weight of ceramic green bodies, less tool equipment and programming, etc., to achieve easy programming control and simple programming. , the effect of convenient integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

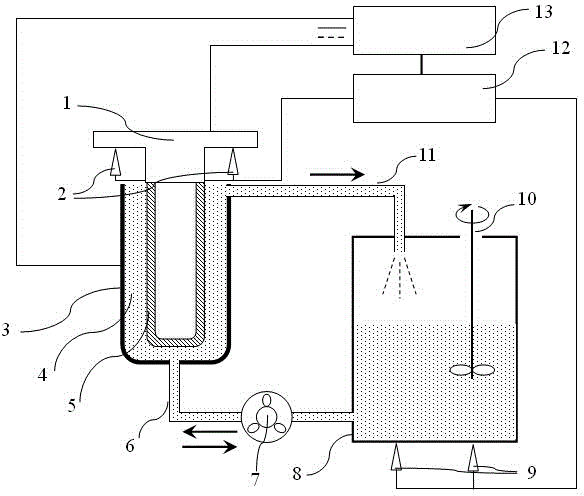

[0024] Below in conjunction with the appendix of the present invention figure 1 , to further describe the method for controlling the weight of the electrophoretic deposition ceramic green body provided by the invention, its specific steps and principles are described as follows:

[0025] (1) First turn on the two-way pump 7 to reverse, pump the slurry in the electrophoresis tank 3 back to the slurry tank until all the slurry in the electrophoresis tank 3 is pumped out, and weigh the weight of the slurry in the slurry tank (The mass of the slurry tank is not included, and the total weight is obtained by subtracting the tare weight of the slurry tank).

[0026] (2) Put the tray mold 1 into the electrophoresis tank 3, and weigh the tray mold 1 (The tray mold is formed by connecting the tray and the mold, the ceramic green body is deposited on the mold, and the tray is used to fix the mold for easy weighing).

[0027] (3) Turn on the two-way pump 7 to rotate forward and deliver t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap