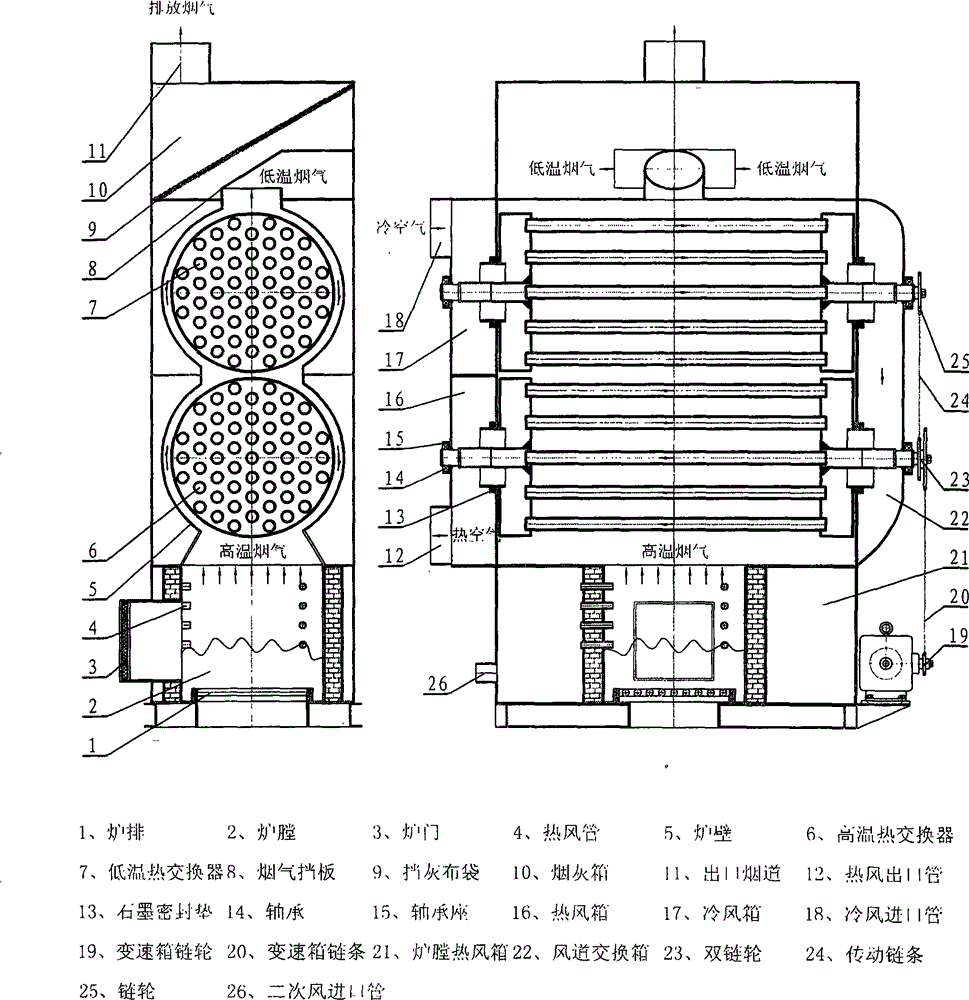

Drum type hot-blast stove

A hot blast stove and drum-type technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of short service life, high power consumption, difficult maintenance, etc., and achieve reduced volume and weight, fuel consumption The effect of sufficient combustion and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

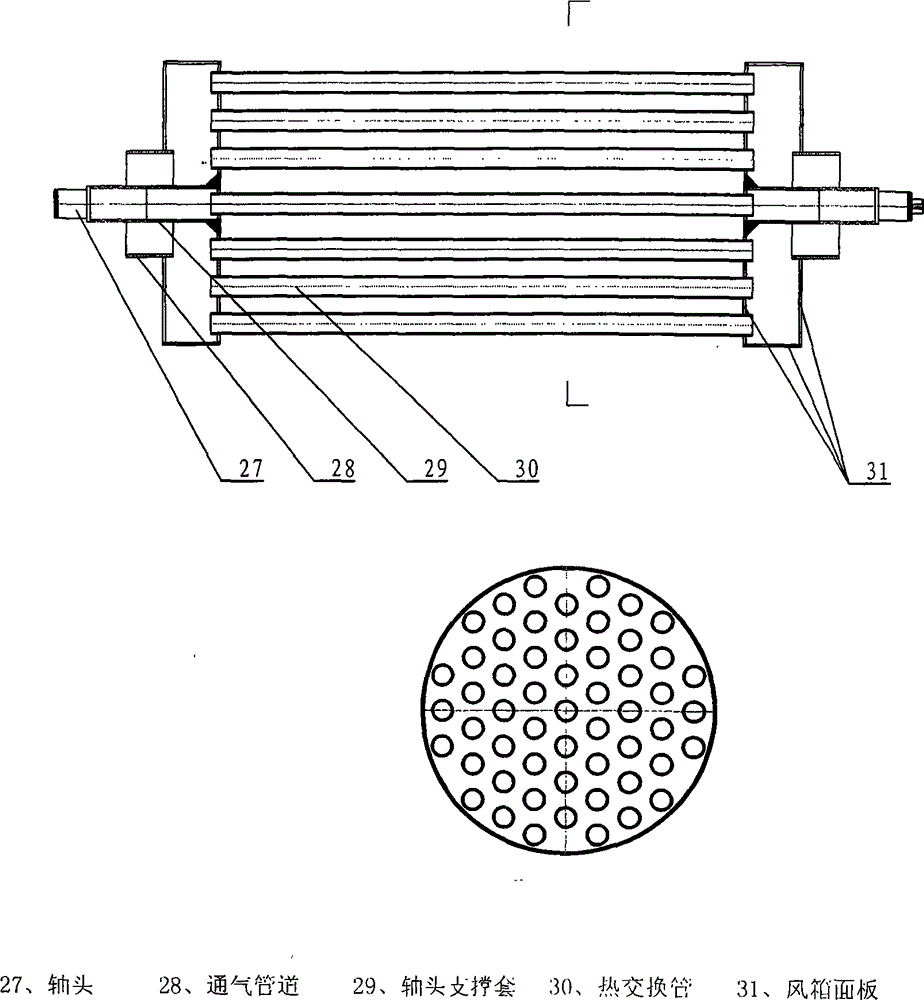

[0017] Shovel natural coal, waste crops and other biofuels into the grate 1 of the furnace 2 from the furnace door 3, turn on the small blower, let the air at room temperature enter from the secondary air inlet pipe 26, and let the high-temperature hot air in the furnace hot air box 21 pass through A plurality of hot air ducts 4 distributed around the furnace 2 are blown into the furnace 2 to allow the fuel to fully burn.

[0018] Turn on the gearbox motor power supply, let the gearbox sprocket 19 drive the high-temperature heat exchanger 6 to rotate and roll through the gearbox chain 20 and the double sprocket 23, and simultaneously the double sprocket 23 drives the low-temperature heat exchanger 6 through the transmission chain 24 and the sprocket 25 synchronously. The exchanger 7 rotates and rolls, and the angular velocity is controlled at about 6 revolutions / minute.

[0019] Turn on the big blower, let the clean cold air enter from the cold air inlet pipe 18, pass through t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap