Novel integral gear shift handle mechanism

A shift handle, an integrated technology, applied in the direction of mechanical equipment, engine components, transmission device control, etc., can solve the problems of easy looseness at the interface, inconvenient use, and remote shift handles, etc., to achieve outstanding substantive features and increase Overall strength, strong and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

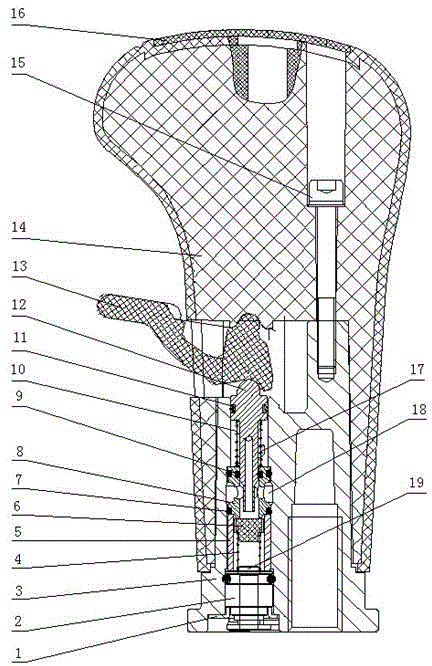

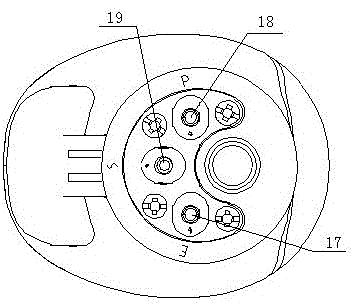

[0014] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0015] It can be seen from the accompanying drawings that a new type of integrated shift handle mechanism includes a shift handle for adjusting different gear positions, and the shift handle is provided with a switching valve for realizing high and low gear conversion of the transmission. The switching valve includes a valve body 3 and a valve core 12, and the valve body 3 is fixed on the handle valve casing 14 through a hexagon socket head screw 15; the valve core 12 is provided with a sealing ring III11, and the valve body 3 and the valve core Between 12, there is also a valve sleeve 8 which plays a sealing role. The valve sleeve 8 is provided with a sealing ring II9. The valve sleeve 8 cooperates with the sealing ring to realize the sealing of the valve core 12. The spool 12 is co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap