Method for using tool for drilling inclined hole

A technology for drilling oblique holes and tooling, which is applied in the field of tooling and fixtures, can solve the problems of unstable positioning of workpiece 1 and unsatisfactory machining accuracy, and achieves the effects of simple structure, high machining accuracy, and economical and practicality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

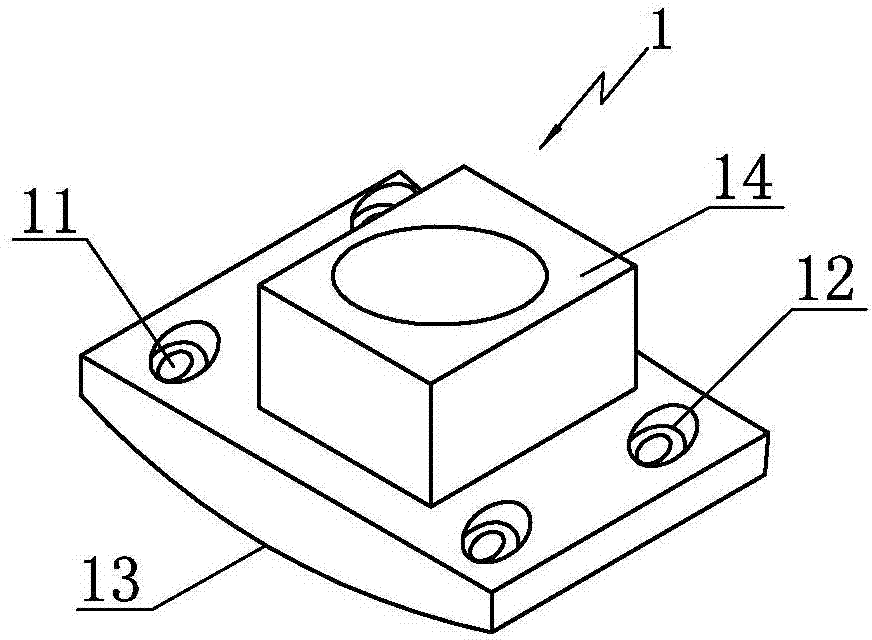

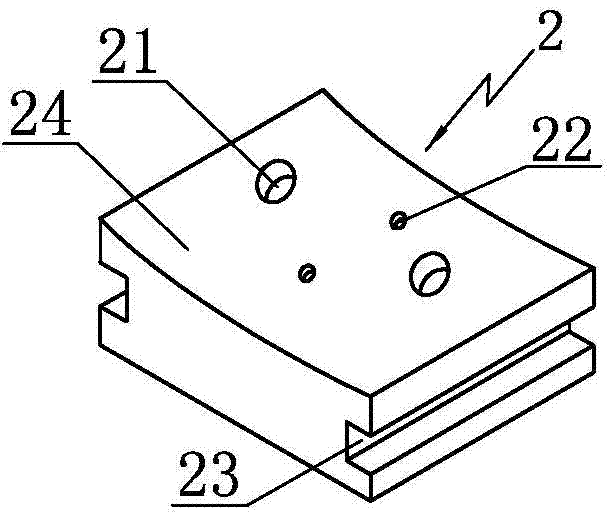

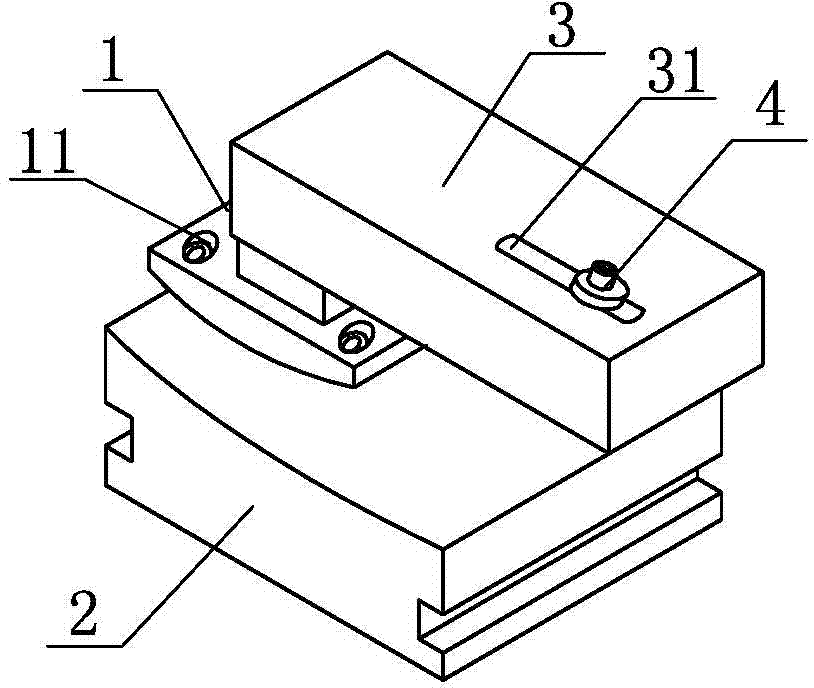

[0015] like Figure 1 to Figure 4 As shown, the present invention includes base plate 2 and briquetting block 3, base plate 2 has arc surface 24, and the arc of arc surface 24 is the same as that of workpiece 1 bottom surface 13, so it can ensure that the bottom surface 13 of workpiece 1 is compared with arc surface 24 The large contact area is conducive to the stable positioning of the workpiece 1; there are two large positioning holes 21 and two small positioning holes 22 on the arc surface 24, and the large positioning holes 21 and the small positioning holes 22 are both oblique and in the same direction. The positioning pin 5 is placed in the small positioning hole 22 to locate the workpiece 1. The two side walls of the base plate 2 have positioning grooves 23, which can fix the base plate 2 on the workbench; It is beneficial to adjust t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap