Two-core twisted-pair cable

A twisted pair cable and main core technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of low shielding performance, insufficient wire core, weak resistance to dragging, etc., and achieve the firmness of the cable core , long service life, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

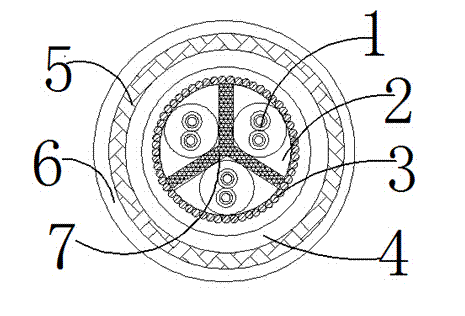

[0010] like figure 1 As shown, a two-core twisted cable includes a main core 1, a tape layer 2, a waterproof layer 3, a shielding layer 4, and a protective sheath 6. The main core 1 is composed of three groups, which are insulated by two tinned The wire core is twisted, and the tin-plated insulated wire core is composed of a pure copper inner conductor, an inner crust layer and an outer conductor braided by copper-aluminum wire, and a reinforcing plate 7 is arranged inside the tape layer 2, so The cross-section of the reinforcing plate 7 is composed of three insulating plates intersecting at one end, and the cladding layer 2 is evenly divided into three panes, the main wire core 1 is respectively located inside the three panes, and the shielding layer 4 is It consists of an inner shield cross-linked with an outer shield.

[0011] As a preferred solution of the present invention, a metal layer 5 is provided between the shielding layer 4 and the protective sheath 6 of the present

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap