Environment-friendly polyethylene/polyamide laminated barrier material and preparation method thereof

A technology of barrier material and polyamide, which is applied in the field of environment-friendly polyethylene/polyamide laminated barrier material, can solve the problems of difficulty in making containers, short production time, low cost, etc., and achieves low equipment requirements and increasingly high barrier performance. , the effect of enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

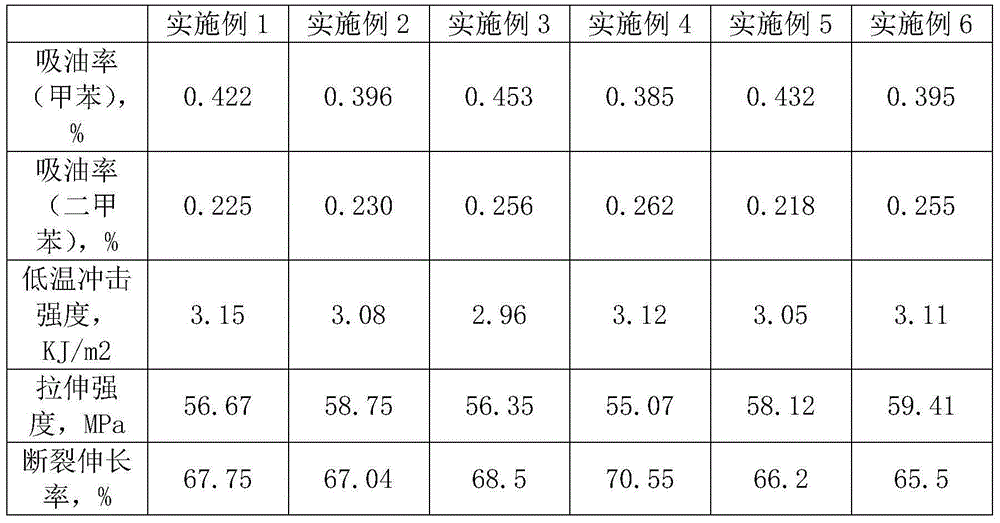

Examples

Embodiment 1

[0032] An environment-friendly polyethylene / polyamide laminate barrier material, in parts by weight, comprises the following components:

[0033] 20 parts of polyamide, 20 parts of polyethylene,

[0034] 5 parts of ethylene-acrylic acid copolymer,

[0035] 2 parts of carbon nanotubes, 1 part of catalyst,

[0036] 2 parts of stabilizer, 3 parts of lubricant.

[0037] Its preparation method comprises the following steps:

[0038] (1) Reflux the carbon nanotubes and concentrated nitric acid solution at 120° C. for 2 hours, filter, and dry in vacuum to obtain carboxylated carbon nanotubes;

[0039] (2) Add polyamide, polyethylene, and ethylene-acrylic acid copolymer into a high-speed mixer, mix and stir for 20 minutes at 8000 rpm and a temperature of 150°C, and continue to add the carboxylated compound obtained in step (1). Carbon nanotubes, catalysts, stabilizers, lubricants, and continue to stir for 20 minutes to obtain a mixed slurry;

[0040] (3) With the mixed slurry obta

Embodiment 2

[0042] An environment-friendly polyethylene / polyamide laminate barrier material, in parts by weight, comprises the following components:

[0043] 50 parts of polyamide, 30 parts of polyethylene,

[0044] 10 parts of ethylene-acrylic acid copolymer,

[0045] 5 parts of carbon nanotubes, 3 parts of catalyst,

[0046] 5 parts of stabilizer, 6 parts of lubricant.

[0047] Its preparation method comprises the following steps:

[0048] (1) Reflux the carbon nanotubes and concentrated nitric acid solution at 150° C. for 3 hours, filter, and dry in vacuum to obtain carboxylated carbon nanotubes;

[0049] (2) Add polyamide, polyethylene, and ethylene-acrylic acid copolymer to a high-speed mixer, mix and stir for 30 minutes at 10,000 rpm and a temperature of 180°C, and continue to add the carboxylated compound obtained in step (1). Carbon nanotubes, catalysts, stabilizers, lubricants, and continue to stir for 50 minutes to obtain a mixed slurry;

[0050] (3) With the mixed slurry ob

Embodiment 3

[0052] An environment-friendly polyethylene / polyamide laminate barrier material, in parts by weight, comprises the following components:

[0053] 30 parts of polyamide, 22 parts of polyethylene,

[0054] 6 parts of ethylene-acrylic acid copolymer,

[0055] 3 parts of carbon nanotubes, 1.5 parts of catalyst,

[0056] 3 parts of stabilizer, 4 parts of lubricant.

[0057] Its preparation method comprises the following steps:

[0058] (1) Reflux the carbon nanotubes and concentrated nitric acid solution at 130° C. for 2.2 hours, filter, and dry in vacuum to obtain carboxylated carbon nanotubes;

[0059] (2) Add polyamide, polyethylene, and ethylene-acrylic acid copolymer to a high-speed mixer, mix and stir for 22 minutes at 8500 rpm and a temperature of 160°C, and continue to add the carboxylated compound obtained in step (1). Carbon nanotubes, catalysts, stabilizers, lubricants, and continue to stir for 30 minutes to obtain a mixed slurry;

[0060] (3) With the mixed slurry o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap