Drilling device for brake drum

A technology of drilling device and brake drum, applied in positioning device, feeding device, boring/drilling and other directions, can solve the problems of reducing the drilling efficiency of brake drum, cumbersome operation and complex overall structure, etc. The overall structure is simple and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

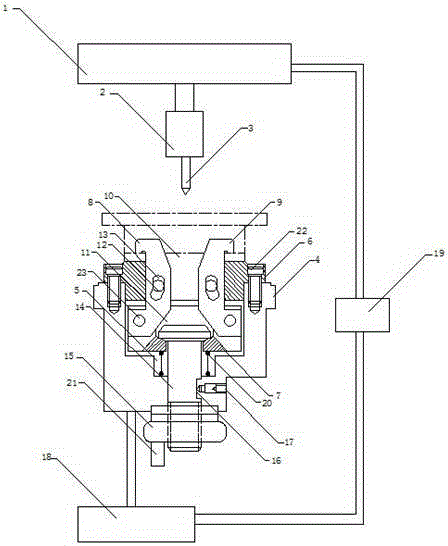

[0014] The reference signs in the drawings of the description include: press 1, motor 2, drill bit 3, base 4, step space 5, upper template 6, lower template 7, left jaw 8, right jaw 9, upper groove 10 , lower groove 11, positioning protrusion 12, guide hole 13, drive rod 14, turntable 15, chute 16, stop screw 17, sheave mechanism 18, controller 19, compression spring 20, handle 21, bolt 22, Pin shaft 23.

[0015] The embodiment is basically as attached figure 1 Shown: the drilling device of the brake drum, including the upper power device, the clamping device and the lower power device, the upper power device includes a press machine 1, a motor 2 fixedly connected to the left side of the press machine 1, and a motor 2 fixedly connected to the left side of the motor 2 Drill bit 3; the clamping device includes a base 4, a clamping mechanism and a driving mechanism, and a ste

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap