Anhydrous deodorant aerosol equipped with a hollow dispensing head

A technology of dispensing head and dispensing hole is applied in the field of dispensing head to achieve the effect of simple structure and reliable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

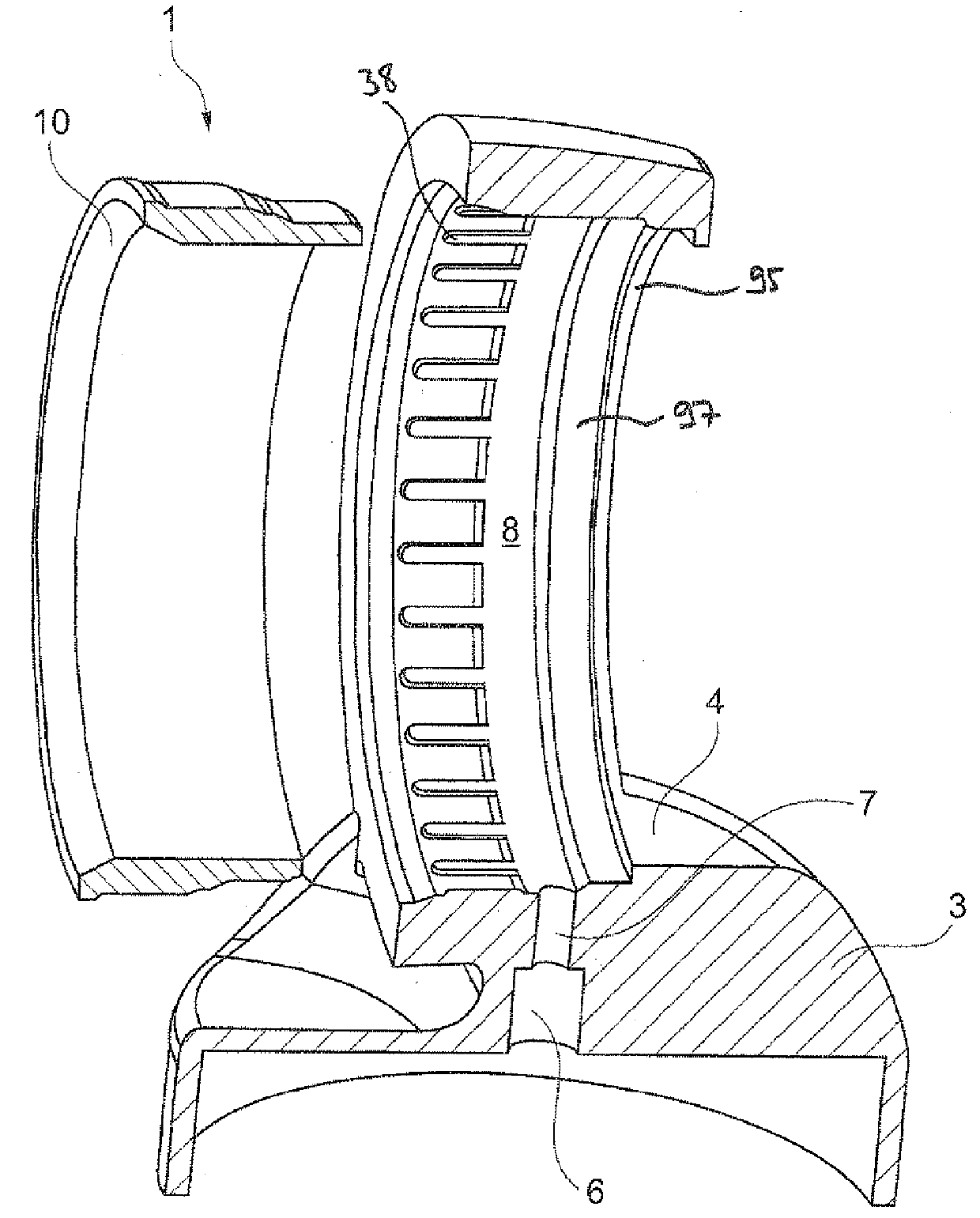

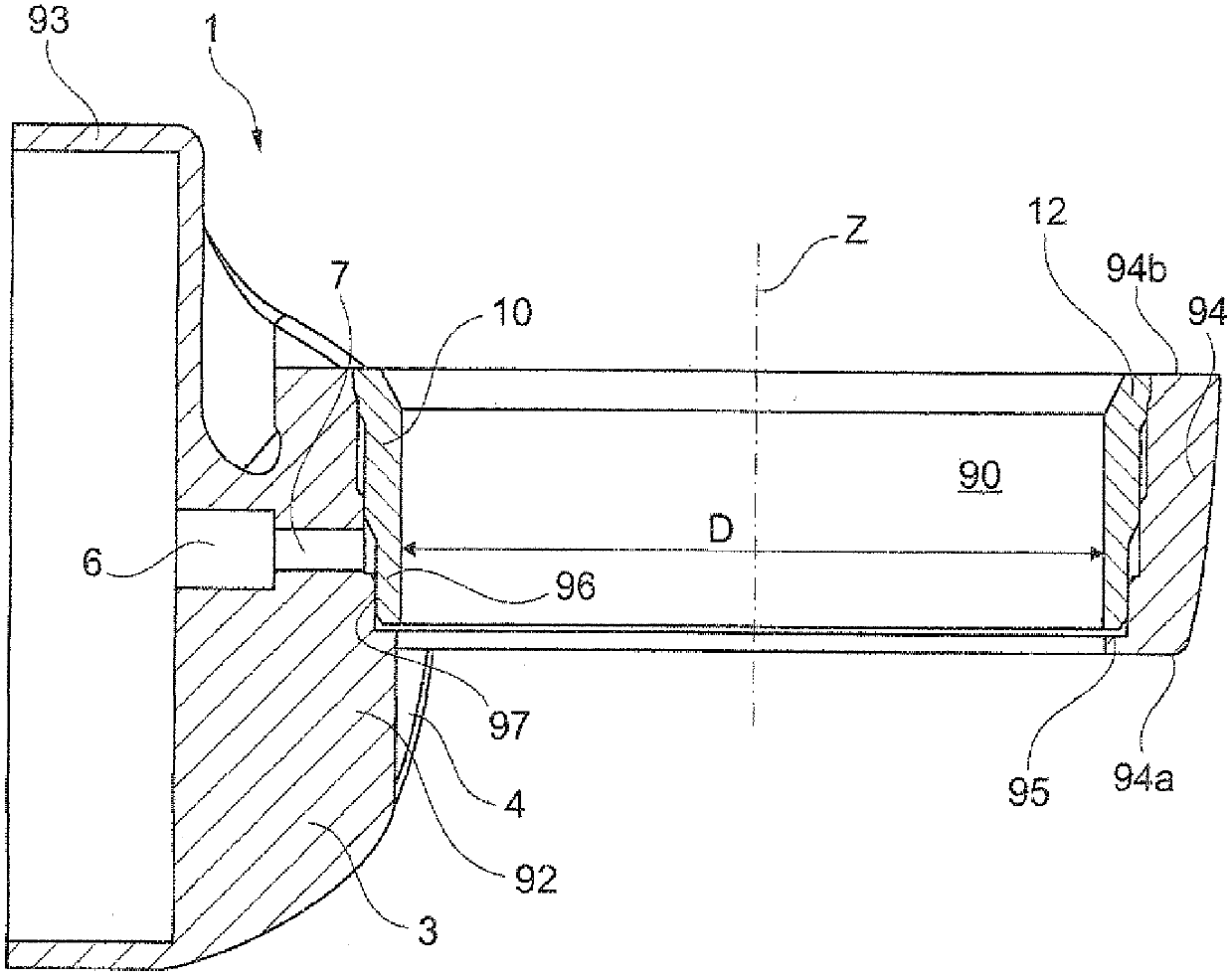

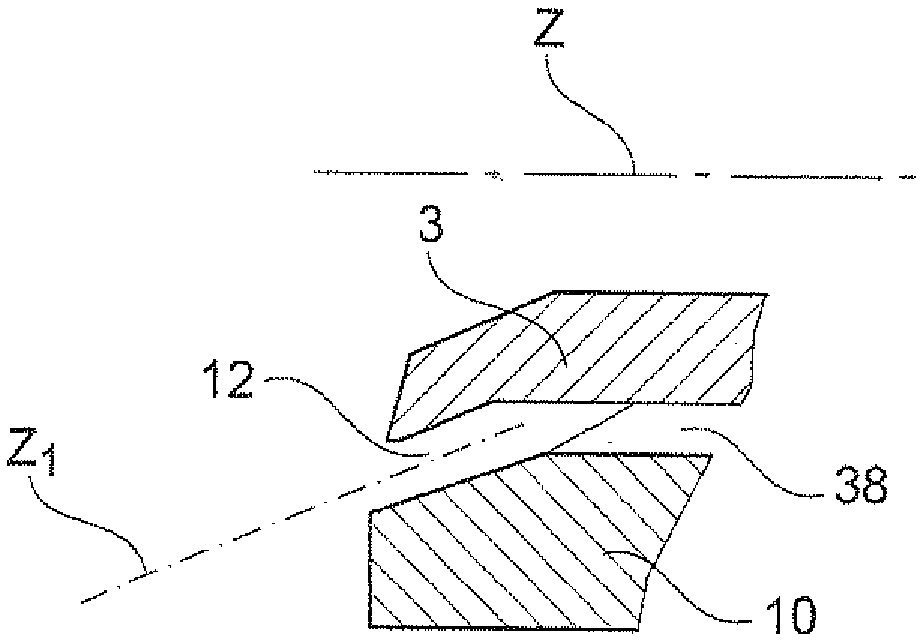

[0150] Figure 1 to Figure 3 The shown dispensing head 1 is intended to fit on a container not shown, which is provided with a hollow valve stem or pump rod through which the product to be dispensed contained in the container is directed towards the dispensing head 1 .

[0151] The container can in particular be a pressurized container of the aerosol canister type containing a propellant gas, for example compressed air or liquefied gas.

[0152] The container can be provided with a valve, and the opening of the valve can take place, for example, by insertion of the hollow rod or alternatively by turning it over. In case the container is equipped with a pump, the actuation of the pump can take place, for example, by the insertion of a hollow rod along its longitudinal axis.

[0153] The dispensing head 1 comprises a body 3 which can be made in one piece from a single piece, or comprise a plurality of elements which are manufactured separately and assembled together.

[0154] lik

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap