A rudder blade installation tool

A technology for installing tooling and rudder blades, applied in the field of ships, can solve the problems of easy dumping, manual movement, time-consuming and labor-intensive, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] preferred embodiment

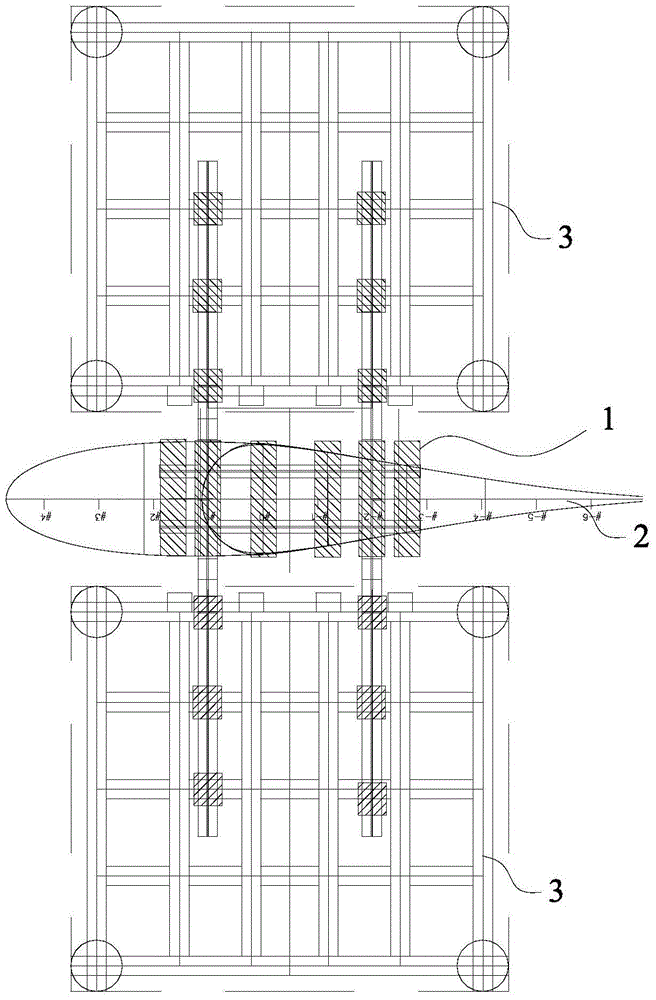

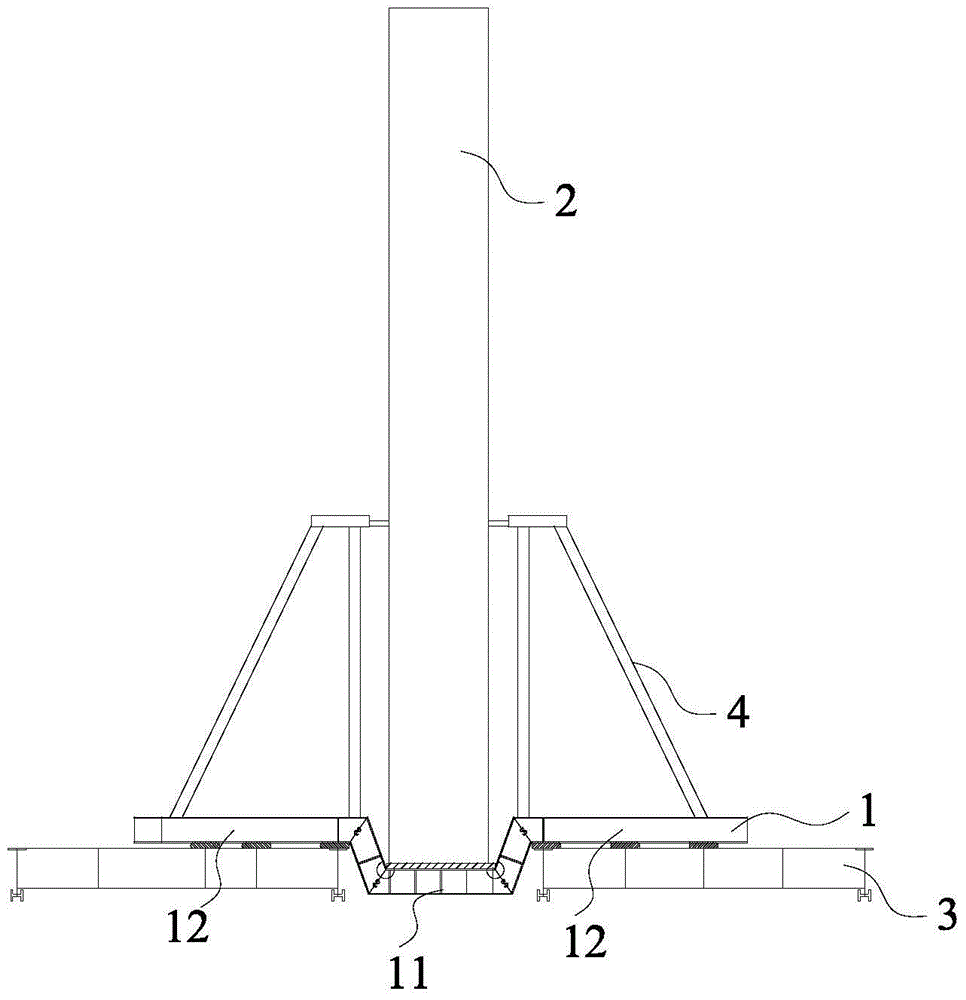

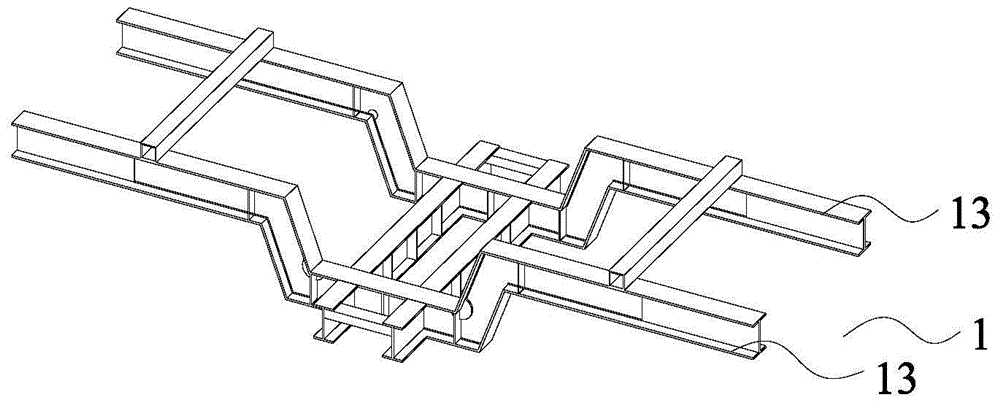

[0028] This embodiment discloses a rudder blade installation tool, such as Figure 1 to Figure 7 As shown, the rudder blade installation tooling includes a support platform 1, the support platform 1 is fixedly connected with the stern operation platform 3, the support platform 1 is provided with a recess 11, and the plane height of the recess 11 is lower than the plane height of the stern operation platform 3, The bottom of the rudder blade 2 is disposed in the recess 11 , and the stern working platform 3 is used for translating and / or jacking up the supporting platform 1 . In this embodiment, the rudder blade installation tool is provided with a support platform 1 on the basis of the stern operation platform 3, and the support platform 1 is provided with a recess 11 lo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap