Mould and method for manufacturing hydrogen fuel cell module used as demonstration teaching aid and cell module

A fuel cell and battery module technology, which is applied in the direction of educational appliances, teaching models, instruments, etc., can solve problems such as time-consuming, long production time, and low production efficiency, and achieve the effects of improving production efficiency, adding functions, and enriching types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

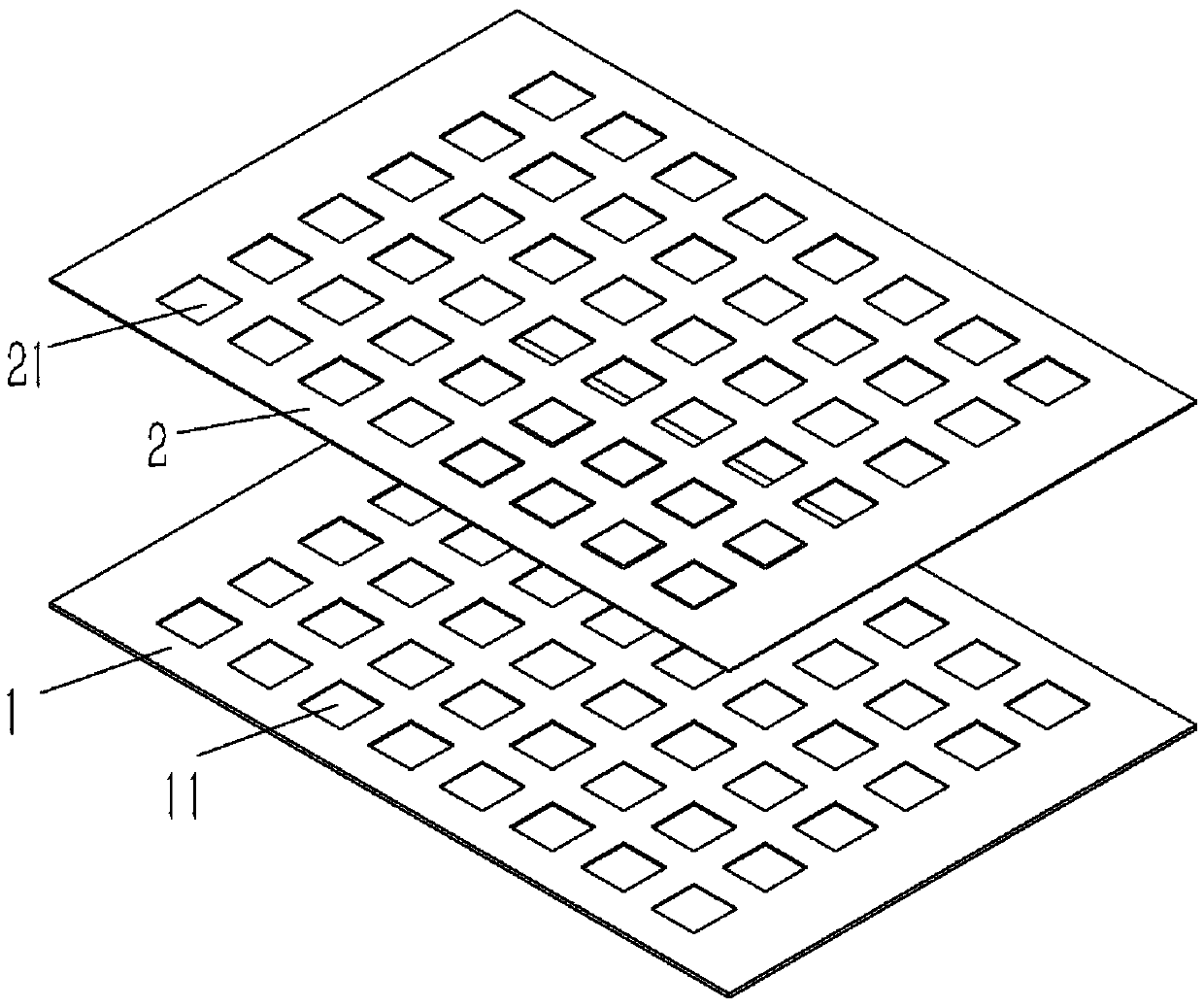

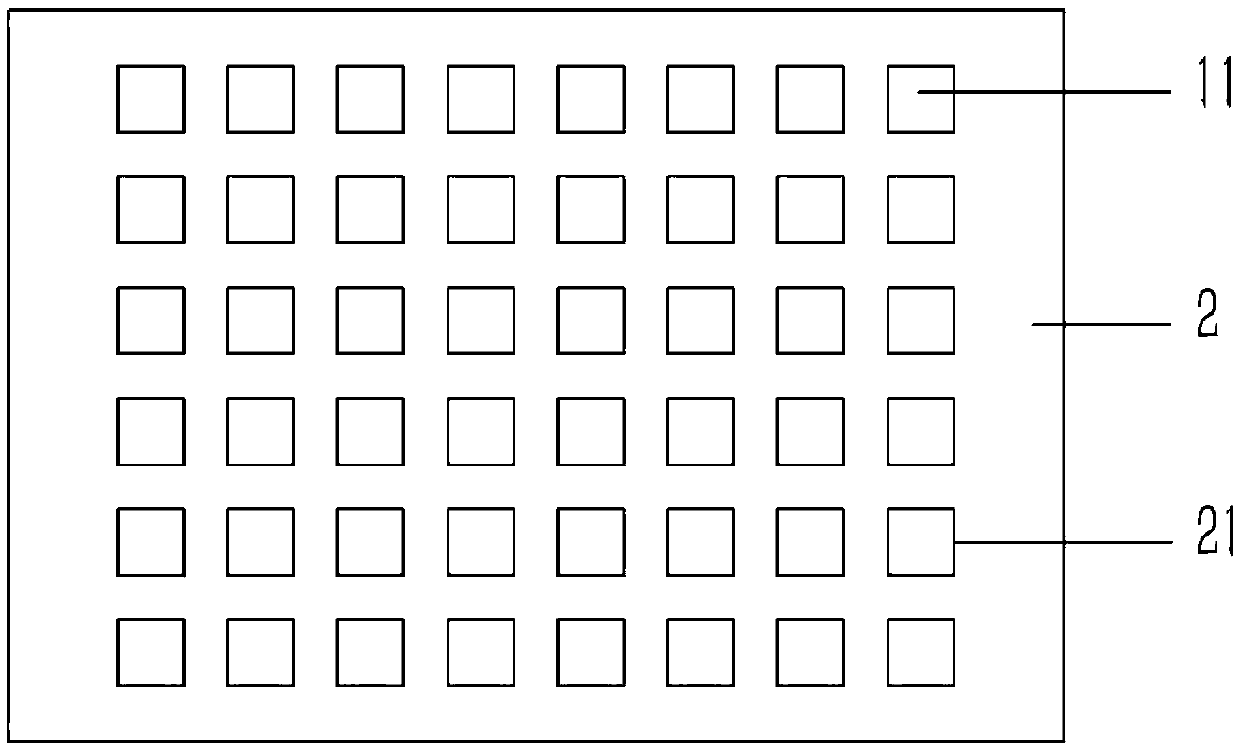

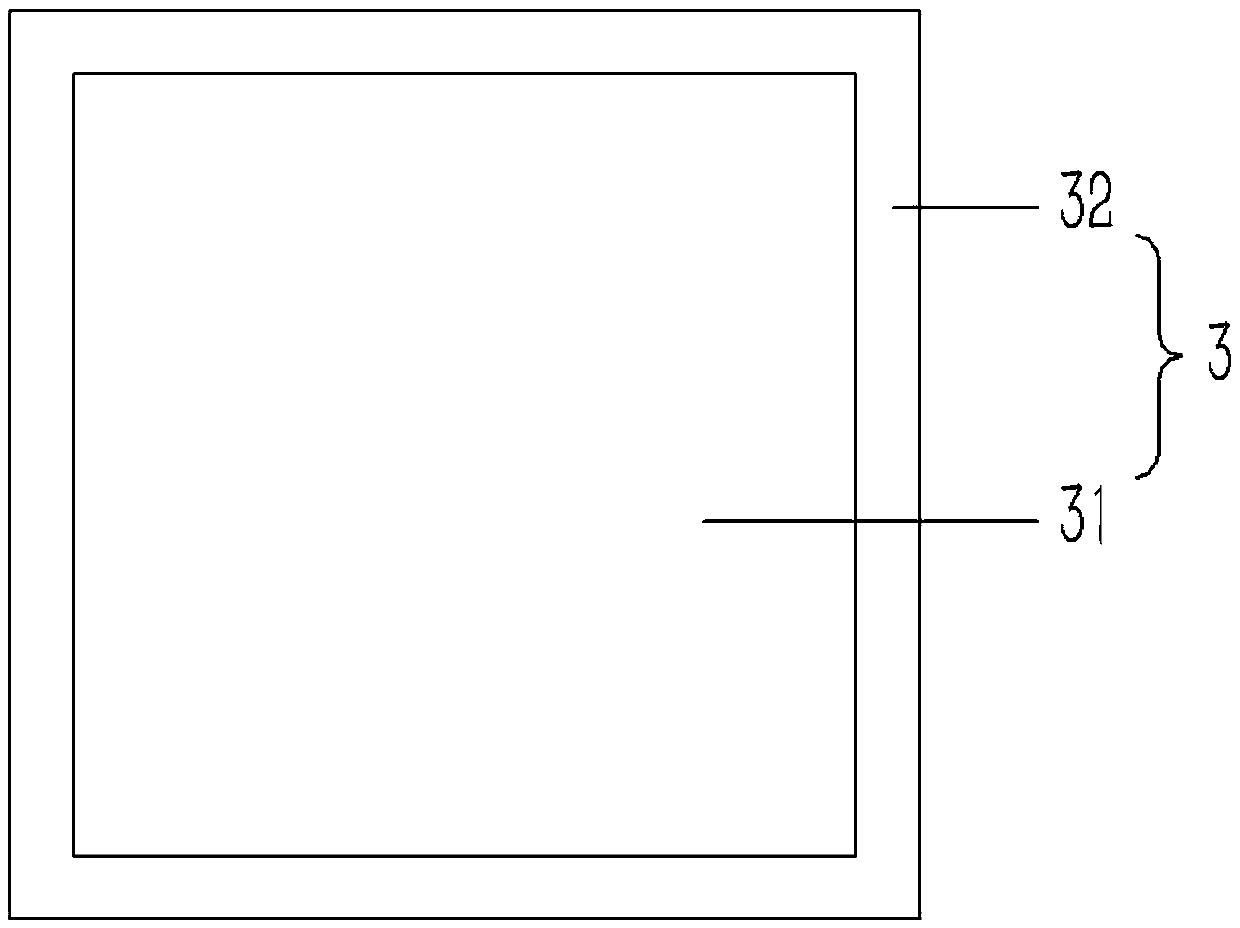

[0025] Example: see Figures 1 to 6 As shown, the mold for making a hydrogen fuel cell module for demonstration teaching aids includes a lower template 1 and an upper template 2. Several rectangular positioning grooves 11 are formed on the upper end surface of the lower template 1, and several rectangular positioning grooves 11 are formed on the upper template 2. The rectangular positioning hole 21 opposite to the positioning groove 11 of the template 1, one side of the upper template 2 and one side of the lower template 1 are fixed together.

[0026] The positioning grooves 11 are linearly and uniformly distributed on the lower template 1, and the positioning holes 21 are linearly and uniformly distributed on the upper template 2; equal.

[0027] The length and width of the lower template 1 are respectively equal to the length and width of the upper template 2 , and the depth of the positioning groove 11 on the lower template 1 is equal to the thickness of the upper template 2

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap