Bending resistant optical fiber

A bending-resistant, optical fiber technology, applied in the direction of glass optical fiber, clad optical fiber, optical waveguide light guide, etc., can solve the problems of optical fiber breakage and unsatisfactory optical fiber bending resistance, and achieve lower use requirements, high curing and ductility , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

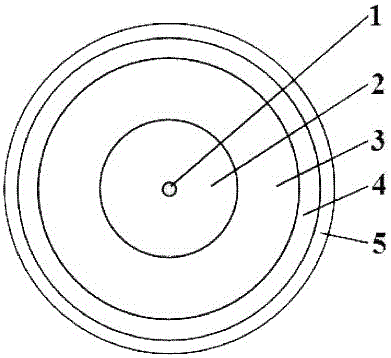

[0036] A bend-resistant optical fiber comprising a core 1, a cladding 2 outside the core, a coating 3 outside the cladding, and a colored layer 5 outside the coating, characterized in that: There is an anti-bending outer layer 4 between the coating layer and the colored layer; the cladding diameter is 123-127 μm, the core / cladding concentricity error is ≤0.6 μm, and the cladding out-of-roundness is ≤1.0%. The diameter of the layer is 210-230 μm, the diameter of the anti-bending outer layer is 225-245 μm, and the diameter of the colored layer is 240-260 μm; after the bending-resistant optical fiber is loosely wound 100 times with a bending radius of 30 mm, the additional attenuation of 1310 nm wavelength is ≤0.05 dB / Km, the additional attenuation of 1383nm wavelength≤0.05dB / Km, the additional attenuation of 1550nm wavelength≤0.1dB / Km, the additional attenuation of 1625nm wavelength≤0.1dB / Km; take any bending-resistant optical fiber with a length of not less than 10cm, and the b...

Embodiment 2

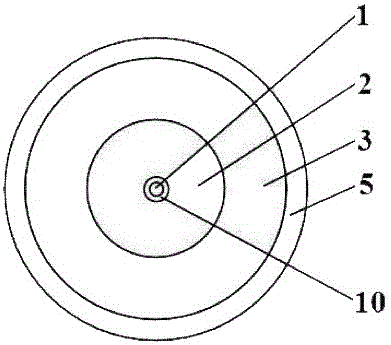

[0053] A bend-resistant optical fiber comprising a core 1, a cladding 2 outside the core, a coating 3 outside the cladding, and a colored layer 5 outside the coating, characterized in that: There is also a bending-resistant inner layer 10 between the core and the cladding; the diameter of the cladding is 123-127 μm, the concentricity error of the core / cladding is ≤0.6 μm, the out-of-roundness of the cladding is ≤1.0%, and the coating layer The diameter is 235-250 μm, the diameter of the anti-bending inner layer is 8.5-20 μm, and the diameter of the colored layer is 240-260 μm; after the bending-resistant optical fiber is loosely wound 100 times with a bending radius of 30 mm, the additional attenuation of 1310nm wavelength is ≤0.05dB / Km, 1383nm wavelength additional attenuation ≤ 0.05dB / Km, 1550nm wavelength additional attenuation ≤ 0.1dB / Km, 1625nm wavelength additional attenuation ≤ 0.1dB / Km; any bend-resistant fiber with a length of not less than 10cm is taken, and the bend...

Embodiment 3

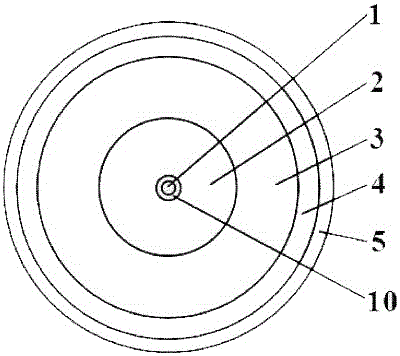

[0070] A bend-resistant optical fiber comprising a core 1, a cladding 2 outside the core, a coating 3 outside the cladding, and a colored layer 5 outside the coating, characterized in that: There is an anti-bending outer layer 4 between the coating layer and the colored layer, and an anti-bending inner layer 10 between the core and the cladding; the diameter of the cladding is 123-127 μm, and the core / cladding concentricity Error ≤ 0.6 μm, cladding out of roundness ≤ 1.0%, coating layer diameter is 210-230 μm; anti-bending inner layer diameter is 8.5-20 μm; anti-bending outer layer diameter is 225-245 μm; coloring layer diameter is 240 ~260μm; after the bend-resistant optical fiber is loosely wound 100 times with a bending radius of 30mm, the additional attenuation of 1310nm wavelength is ≤0.05dB / Km, the additional attenuation of 1383nm wavelength is ≤0.05dB / Km, and the additional attenuation of 1550nm wavelength is ≤0.1dB / Km, 1625nm wavelength additional attenuation ≤ 0.1dB / K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap