Single motor input optical fiber grinding machine core assembly

A technology of input optical fiber and single motor, which is applied in the direction of grinding machine tools, grinding devices, grinding tools, etc., can solve the problems of poor synchronization, large deceleration space, and shortened life, so as to improve revolution stability, ensure parallelism and coaxiality degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

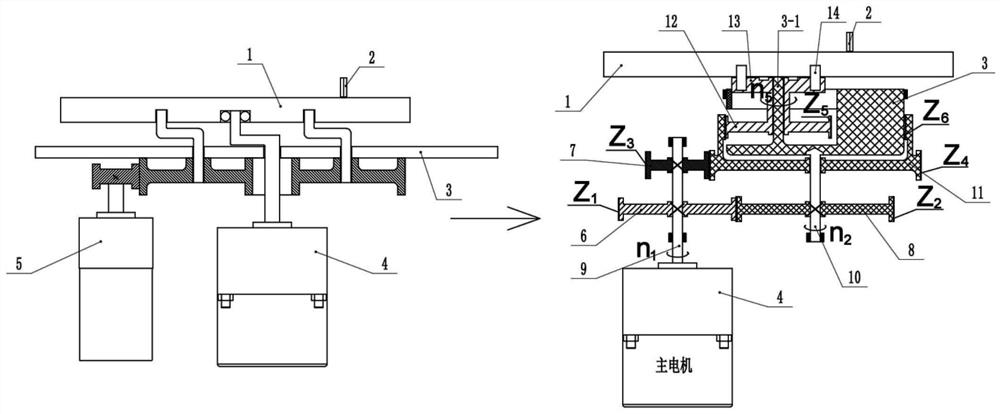

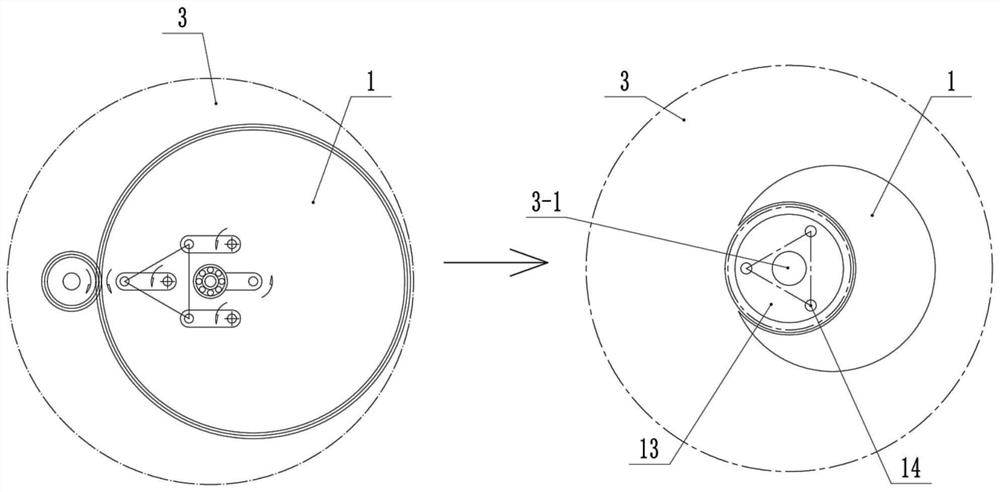

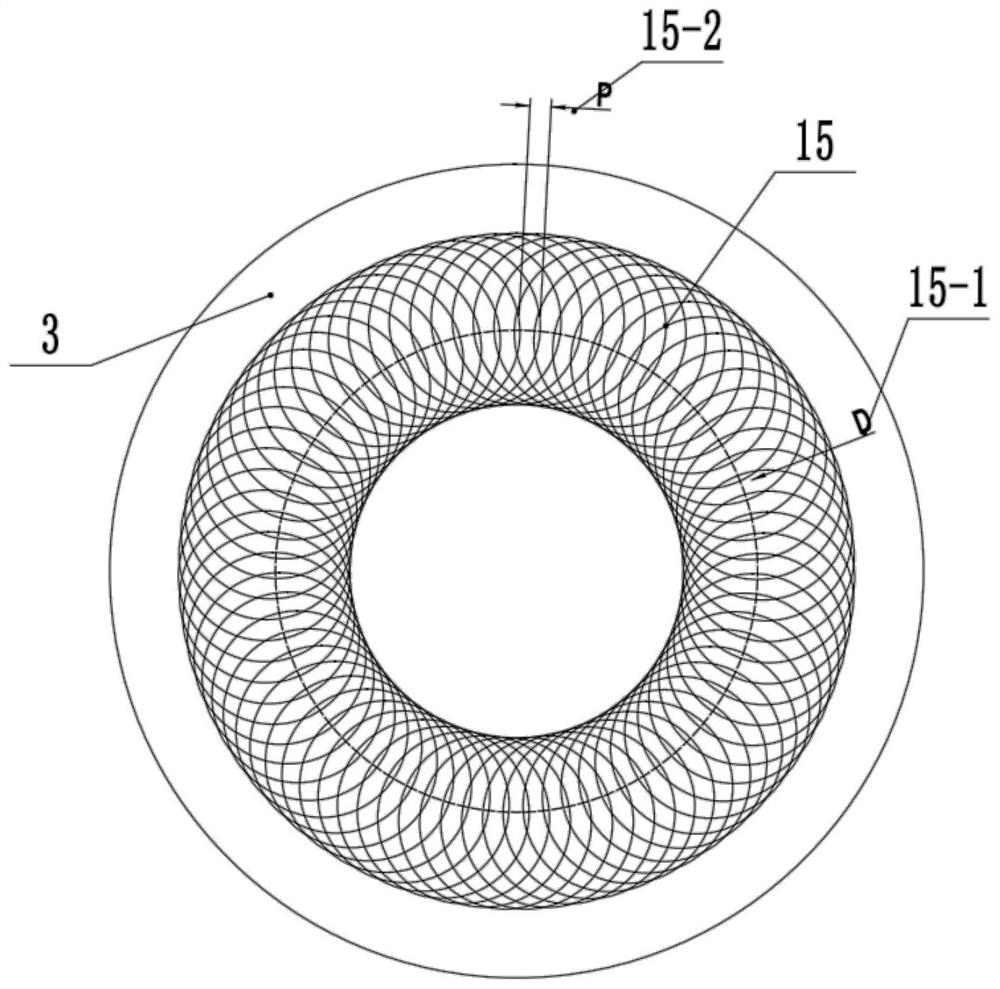

[0018] like Figure 1-3 As shown, the device mainly includes a grinding chassis 1, a grinding auxiliary disc 3, a main motor 4, and a grinding track 15. An optical fiber ceramic ferrule 2 to be ground is installed on the top of the grinding chassis 1, and a grinding connection is connected to the bottom of the grinding chassis 1. disc 13, the grinding connecting disc 13 is connected with the main motor 4 for speed regulation, the original grinding structure, the auxiliary motor 5 drives the grinding auxiliary disc 3 to rotate, and the grinding auxiliary disc 3 is installed at the bottom of the grinding chassis 1 , the grinding chassis 1 produces the grinding track 15 when grinding the fiber optic ceramic ferrule 2, the main parameters of the grinding track 15 include a helical pitch 15-1 and a grinding main diameter 15-2; the main motor 4 outside Even with the main input shaft 9, the main input shaft 9 is sequentially installed with a first-stage gear A6 and a first-stage gear B7

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap