Deep design system and method for parts

A design system and design method technology, applied in computing, special data processing applications, instruments, etc., to achieve the effect of improving product production efficiency, good market prospects, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

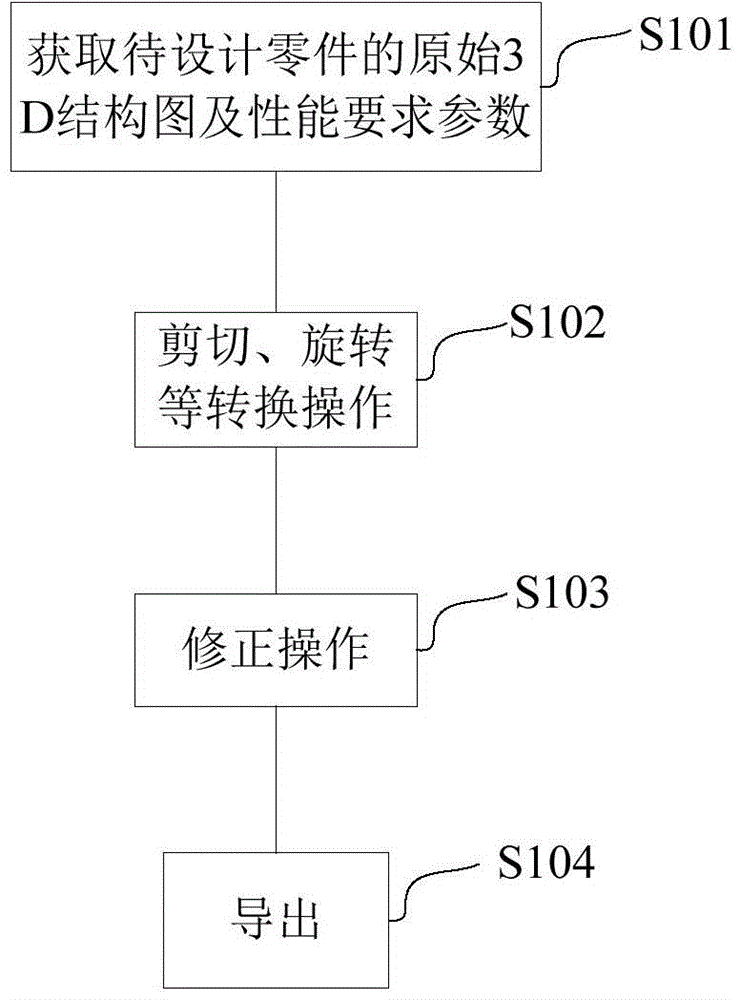

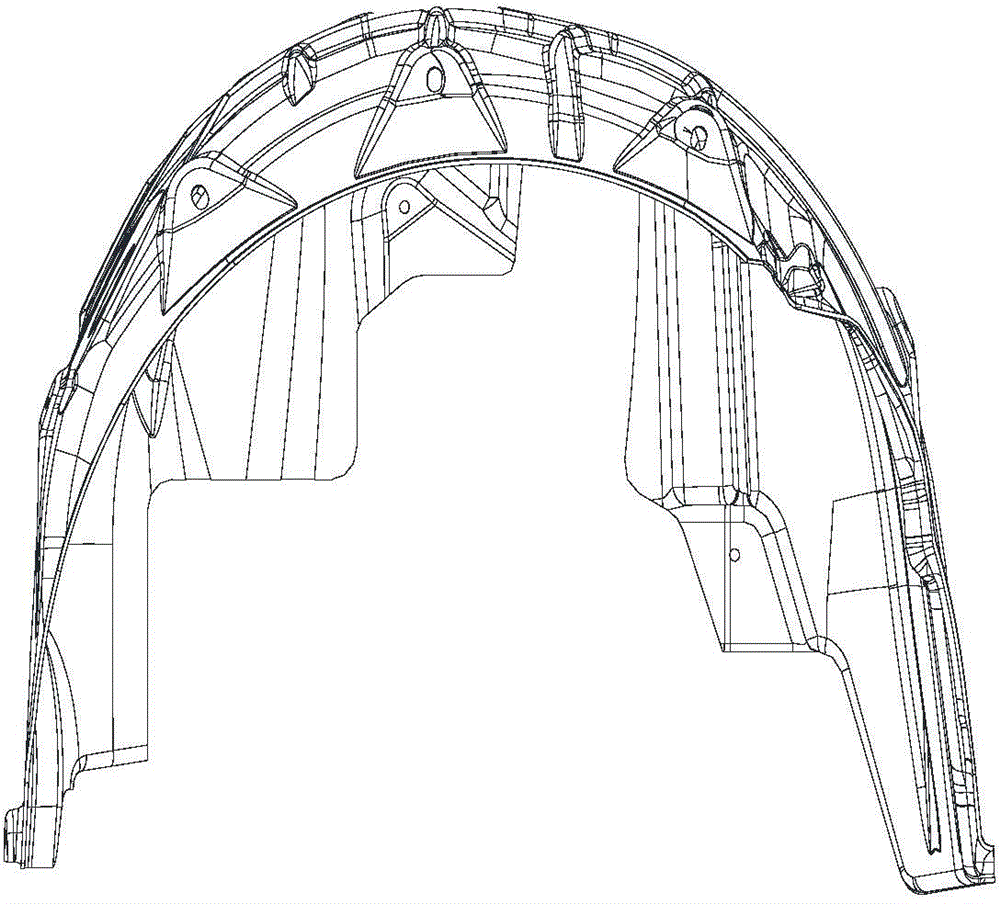

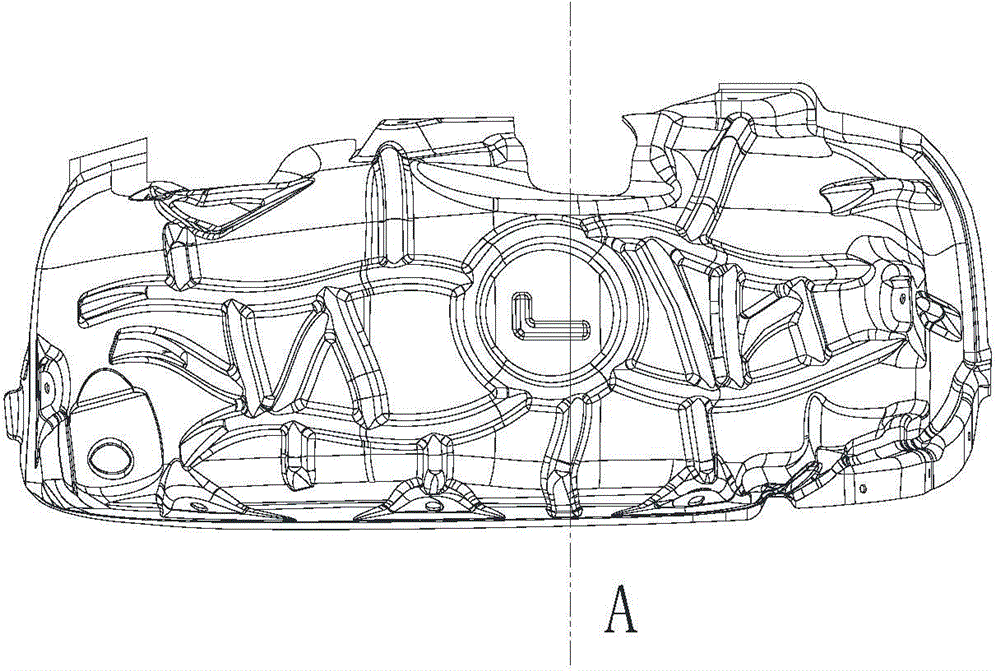

[0033] This embodiment provides a part depth design system, which runs in a computer and includes an acquisition module, a conversion module, a correction module and an export module, wherein the acquisition module is used to obtain the original 3D structure diagram and performance requirement parameters of the part to be designed; conversion The module is used to convert the original 3D structure diagram, reduce the difficulty of mold design of the part to be designed based on the performance requirement parameters, and obtain the converted 3D structure diagram; the correction module is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap