Voltage feedback-based white LED oscillatory efficiency drive system

A voltage feedback, high-efficiency driving technology, applied in electric light sources, electroluminescent light sources, light sources, etc., can solve the problems of high energy consumption and low driving efficiency, and achieve the effects of low power consumption, high driving efficiency, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example

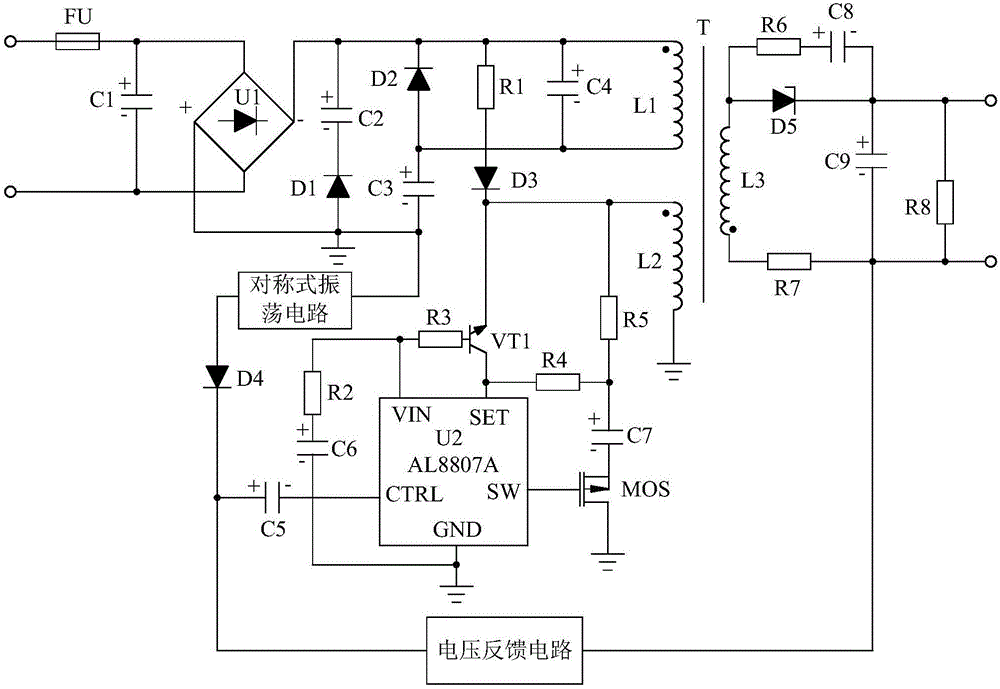

[0022] Such as figure 1 As shown, the white LED oscillation high-efficiency drive system based on voltage feedback of the present invention is mainly composed of transformer T, power supply circuit, microprocessor circuit, symmetrical oscillation circuit, high-efficiency step-down drive circuit, voltage feedback circuit and secondary output The circuit consists of seven parts.

[0023] Such as figure 1 As shown, the microprocessor circuit is connected in series between the primary inductor coil L1 of the transformer T and the power supply circuit, the symmetrical oscillation circuit is connected to the power supply circuit, and the high-efficiency step-down drive circuit is connected to the symmetrical oscillation circuit and The micro-processing circuit is connected, the secondary output circuit is connected to the secondary inductor L3 of the transformer T, and the voltage feedback circuit is connected in series between the secondary output circuit and the high-effi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap