Preparation method of LED chip and LED chip prepared by adopting method

A technology of LED chips and anti-reflection coatings, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems that the ITO transparent conductive layer is easily damaged and polluted, and affect the brightness of LEDs, so as to reduce the risk of the current blocking layer and avoid Damage and contamination, the effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

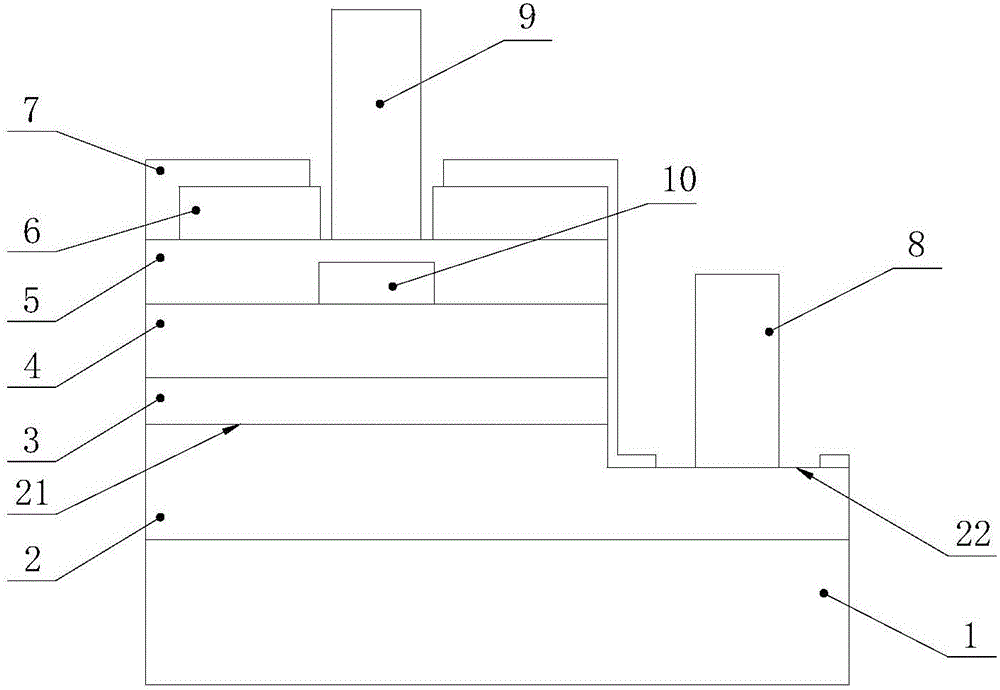

[0032] see figure 1 , a kind of LED chip of the present invention, this LED chip comprises substrate 1, epitaxial layer and electrode successively in thickness direction, and epitaxial layer comprises N-type semiconductor layer 2, light emitting layer 3 and P-type semiconductor layer 4, N-type semiconductor layer 2 is a stepped structure including an upper stepped portion 21 and a lower stepped portion 22, the light emitting layer 3 and the P-type semiconductor layer 4 are sequentially arranged above the upper stepped portion 21, and an ITO transparent conductive layer is also provided on the P-type semiconductor layer 4 5. The electrodes include an N electrode 8 arranged on the lower step portion 22 and a P electrode 9 arranged on the ITO transparent conduct

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap