Refining method for high-purity bepotastine besilate

A technology of bepotastine bepotastine and its refining method, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve problems such as impurity A cannot be effectively removed, impurity cannot be effectively removed, and cannot be recycled and refined. , to achieve the effects of low production cost, cost saving and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

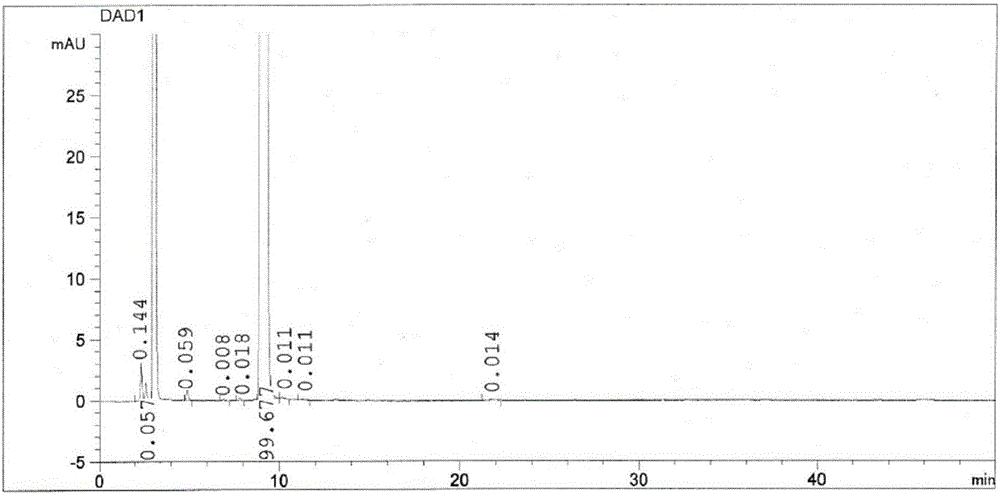

Embodiment 1

[0057] The refining method of high-purity bepotastine bepotastine in the present embodiment comprises the following steps:

[0058] 1. Add 20 g of crude bepotastine besilate to 200 ml of acetonitrile, heat to 80°C, stir to dissolve and filter, cool the filtrate to 25-30°C, stir and crystallize for 6 hours, filter, and dry the filter cake at 60°C under reduced pressure After 4 hours, 18.3 g of the primary refined product was obtained, with a yield of 91.5% and a purity of 99.89%.

[0059] 2. Add 18g of the primary refined product to 90ml of water, heat to 30-40°C, stir to dissolve, cool to -1-5°C, stir and crystallize for 6h, filter, and dry the filter cake at 40°C for 12h under reduced pressure to obtain benzenesulfonate Bepotastine pure product 16.3g, yield 90.6%, purity 99.99%.

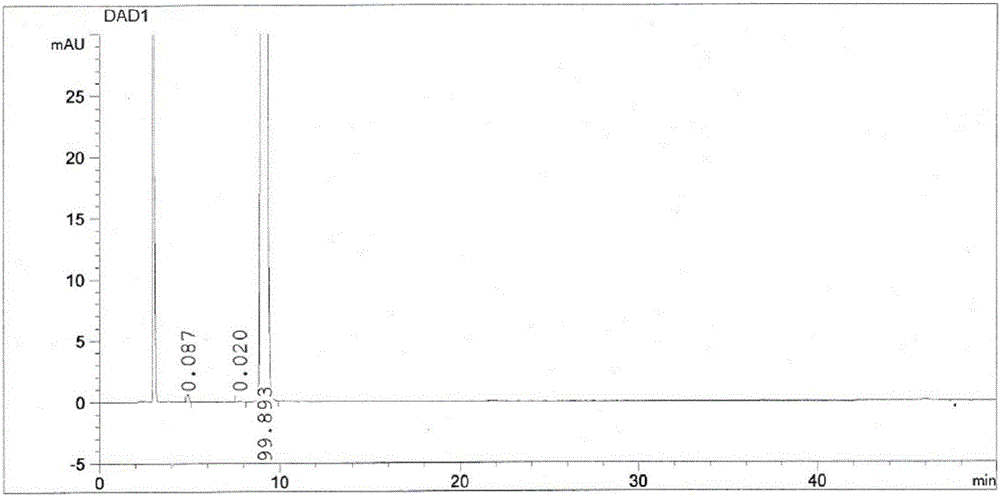

Embodiment 2

[0061] 1. Add 20 g of crude bepotastine besilate to 300 ml of acetonitrile, heat to 60°C, stir to dissolve and filter, cool the filtrate to 10-20°C, stir and crystallize for 8 hours, filter, and dry the filter cake at 50°C under reduced pressure After 5 hours, 18.4 g of the primary refined product was obtained, with a yield of 92% and a purity of 99.90%.

[0062] 2. Add 18g of the primary refined product to 35ml of water, heat to 70°C, stir to dissolve, cool down to -1-5°C, stir and crystallize for 4h, filter, and dry the filter cake at 50°C for 10h under reduced pressure to obtain bezulbeta The pure product of Sting is 16.4g, the yield is 91.1%, and the purity is 99.96%.

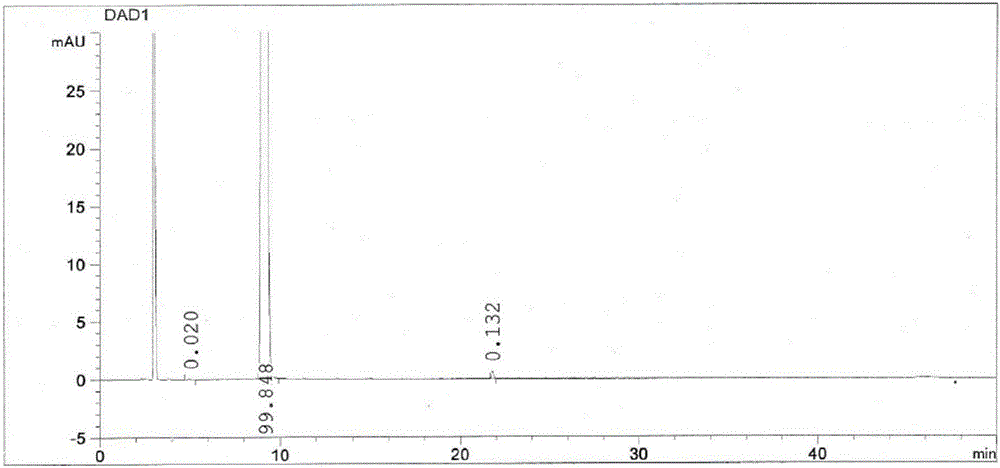

Embodiment 3

[0064] 1. Add 100g of crude bepotastine besilate to 1000ml of acetonitrile, heat to 90°C, stir to dissolve and filter, cool the filtrate to 20-30°C, stir and crystallize for 6h, filter, and dry the filter cake at 70°C under reduced pressure After 4 hours, 92.8 g of the primary refined product was obtained, with a yield of 92.8% and a purity of 99.88%.

[0065] 2. Add 92g of the primary refined product to 270ml of water, heat to 50°C, stir to dissolve, cool to -1-5°C, stir and crystallize for 5h, filter, and dry the filter cake at 55°C for 10h under reduced pressure to obtain besylate The pure product of Sting is 84.8g, the yield is 92.2%, and the purity is 99.97%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap