Rotation material taking structure of die bonder

A die-bonding machine and die-bonding technology, which is used in conveyor objects, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of complex structure and high cost, and achieve the effect of ingenious structure, cost saving and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

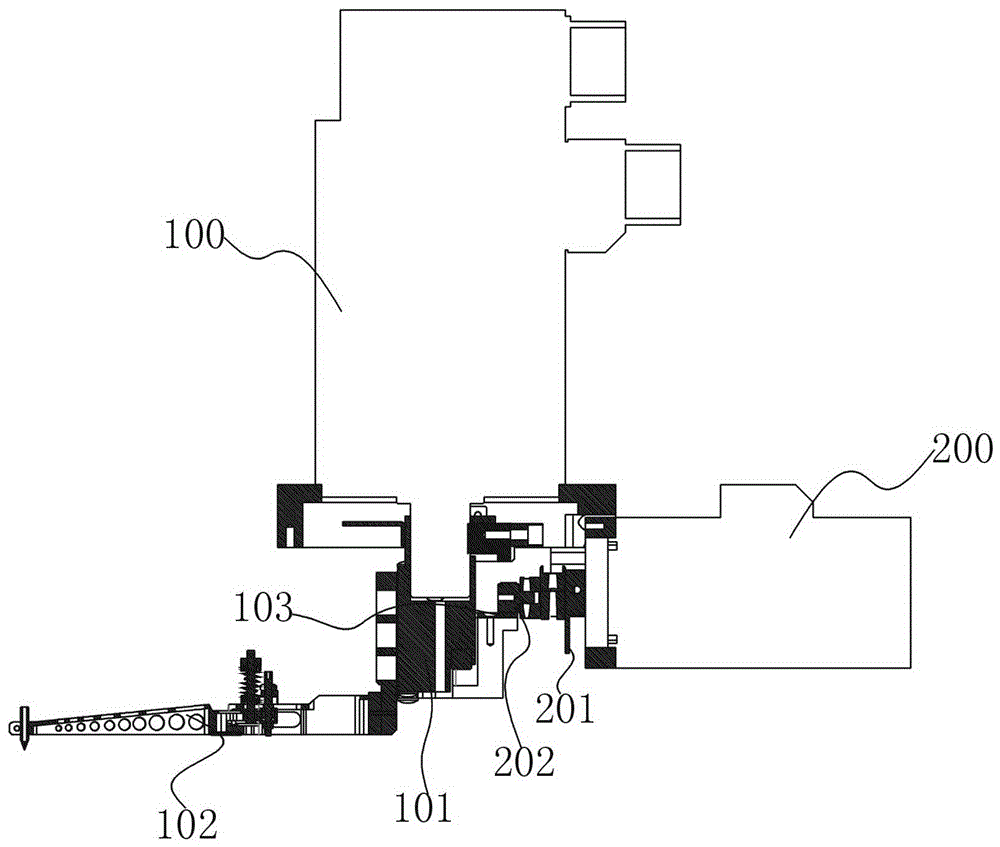

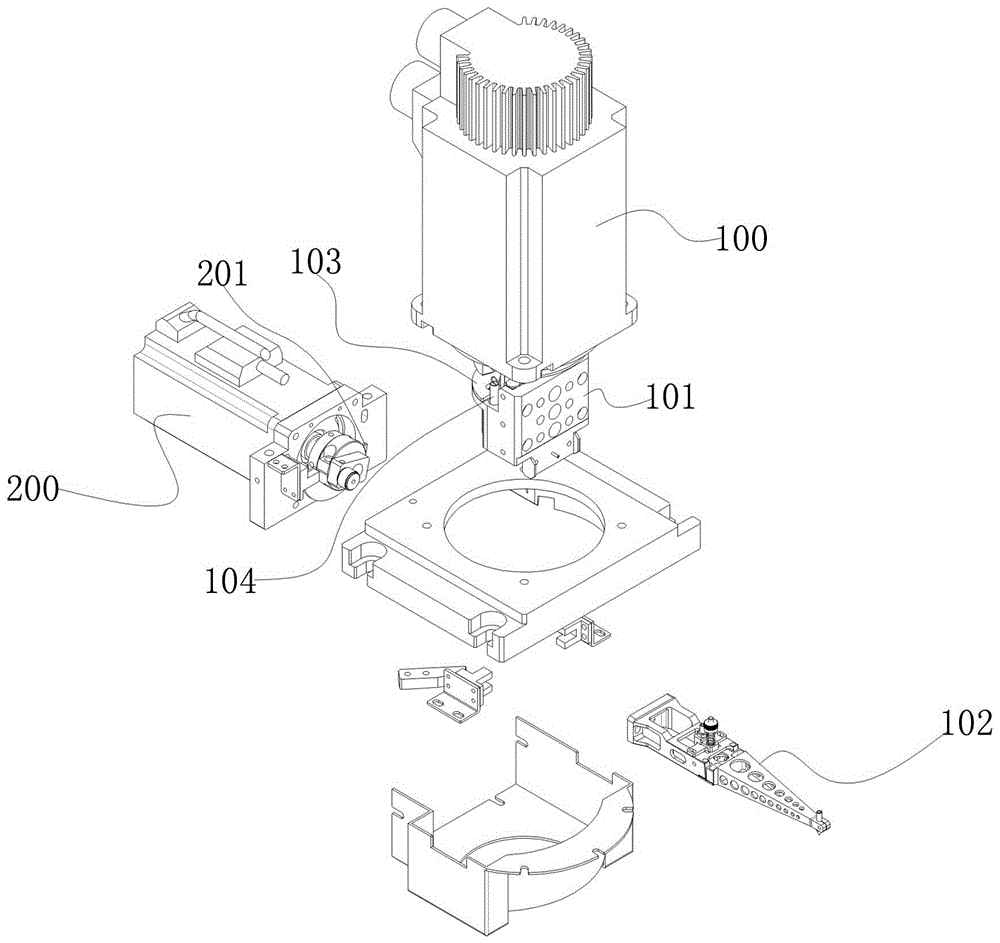

[0011] to combine figure 1 and figure 2 , which describes the specific implementation of the present invention in detail, but does not limit the claims in any way.

[0012] In the implementation of the present invention, the rotary reclaiming structure of the solid crystal machine includes a vertically arranged rotating motor 100, and a horizontally arranged lifting motor 200 is provided below the rotating motor 100; the motor of the lifting motor 200 A needle bearing 202 and a rotation induction piece 201 are arranged on the shaft, and the needle bearing 202 is connected with a lifting seat 101, which is arranged on the motor shaft of the rotating motor 100 and is driven to rotate by the rotating motor 100; the lifting seat 101 is connected with a crystal-bonding bracket 102 . The lifting seat 101 is provided with a wear-resistant plate 103, and a return spring 104 is arranged between the lifting seat 101 and the rotating motor 100, which is used to assist the lifting seat 10

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap