Lightweight differential assembly

A differential and lightweight technology, which is applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of increasing the axial length of the half shaft, increasing the weight of the left case of the differential, and increasing the weight of the right differential. Problems such as increased shell weight, to achieve the effect of increasing axial length, shortening length, reducing weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated in conjunction with the accompanying drawings.

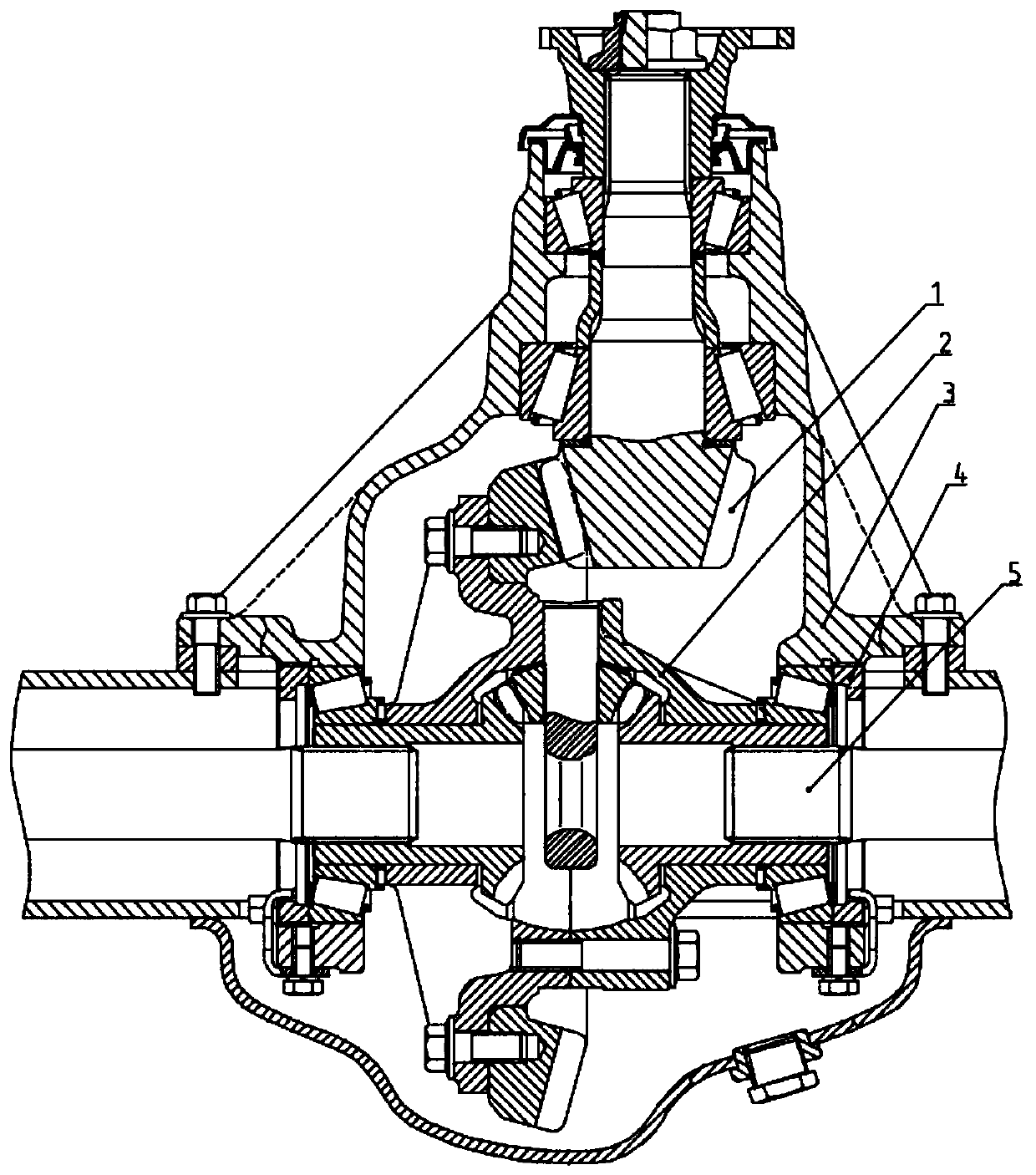

[0015] Such as figure 1 As shown, the lightweight differential assembly structure of the present invention is applied to the view of the rear axle assembly. The bevel teeth of the driven bevel gear 11 in the differential assembly 2 mesh with the bevel teeth of the driving bevel gear 1; Fitting; the end face of the adjusting ring 4 fits with the end faces of the two tapered roller bearings 6 in the differential assembly 2; the spline hole of the side gear 9 in the differential assembly 2 and the spline shaft of the half shaft 5 connect.

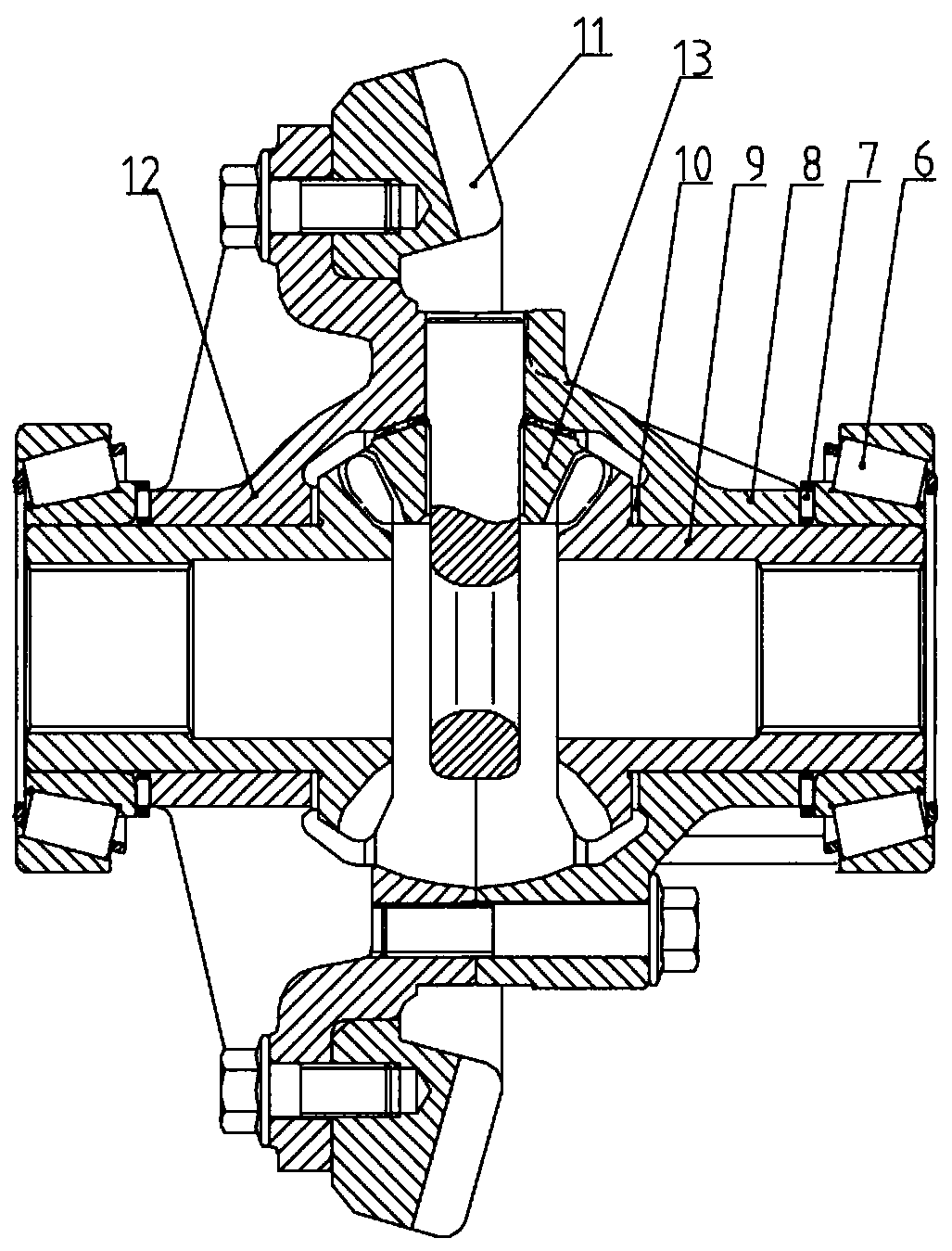

[0016] Such as figure 2 As shown, the shaft diameter of the side gear 9 matches the round hole of the differential right case 8, and the side gear spacer 10 is used between the shoulder plane of the side gear 9 and the plane of the differential right case 8, and the half shaft The bevel teeth of the shaft gear 9 mesh with the bevel teeth

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap