Carbon-nitrogen material loaded cobalt catalyst and method for synthesizing pimavanserin intermediate

A technology of cobalt catalyst and carbon-nitrogen material, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of poor chemical stability, unfavorable industrial applications, hidden safety hazards, etc., and achieve convenient synthesis process and reduce Synthesis cost, life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The synthesis of embodiment 1 catalyst A

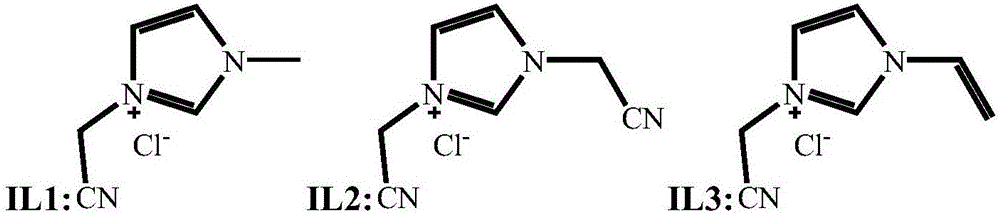

[0020] Weigh 0.249g of cobalt acetate tetrahydrate in a round bottom flask, 30ml of methanol as a solvent, then add 0.472g of IL1 (the molar ratio of metal cobalt compound to IL1 is 1:3), stir at room temperature for 30min, then slowly add 1.0g of activated carbon (Based on a Co loading of 6% by mass). Put the round-bottomed flask into an oil bath at 50° C. and heat and stir for 5 h, then remove the solvent methanol by rotary evaporation. The obtained supported pre-catalyst was vacuum-dried at 60° C. for 12 hours. The dried pre-catalyst was placed in a tube furnace and calcined at 800°C for 2h under nitrogen (heating rate 5°C / min). After naturally lowering to constant temperature, catalyst A was obtained.

Example Embodiment

[0021] The synthesis of embodiment 2 catalyst B

[0022] Weigh 0.249g of cobalt acetate tetrahydrate in a round bottom flask, 30ml of methanol as a solvent, then add 0.547g of IL2 (the molar ratio of metal cobalt compound to IL2 is 1:3), stir at room temperature for 30min, then slowly add 1.0g of activated carbon (Based on a Co loading of 6% by mass). Put the round-bottomed flask in an oil bath at 55° C. and heat and stir for 5 h, then remove the solvent methanol by rotary evaporation. The obtained supported pre-catalyst was vacuum-dried at 60° C. for 12 hours. The dried pre-catalyst was placed in a tube furnace and calcined at 800°C for 2h under nitrogen (heating rate 5°C / min). After naturally lowering to a constant temperature, catalyst B was obtained.

Example Embodiment

[0023] The synthesis of embodiment 3 catalyst C

[0024] Weigh 0.249g of cobalt acetate tetrahydrate in a round bottom flask, 30ml of methanol as a solvent, then add 0.508g of IL3 (the molar ratio of metal cobalt compound to IL3 is 1:3), stir at room temperature for 30min, then slowly add 1.0g of activated carbon (Based on a Co loading of 6% by mass). Put the round-bottomed flask into an oil bath at 50° C. and heat and stir for 6 h, then remove the solvent methanol by rotary evaporation. The obtained supported pre-catalyst was vacuum-dried at 60° C. for 12 hours. The dried pre-catalyst was placed in a tube furnace and calcined at 800°C for 2h under nitrogen (heating rate 5°C / min). After naturally lowering to a constant temperature, catalyst C was obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap