Material packaging and bending device

A material package and slider technology, applied in the direction of folding thin materials, transportation and packaging, thin material processing, etc., to achieve the effects of avoiding package folding skew, small space occupation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

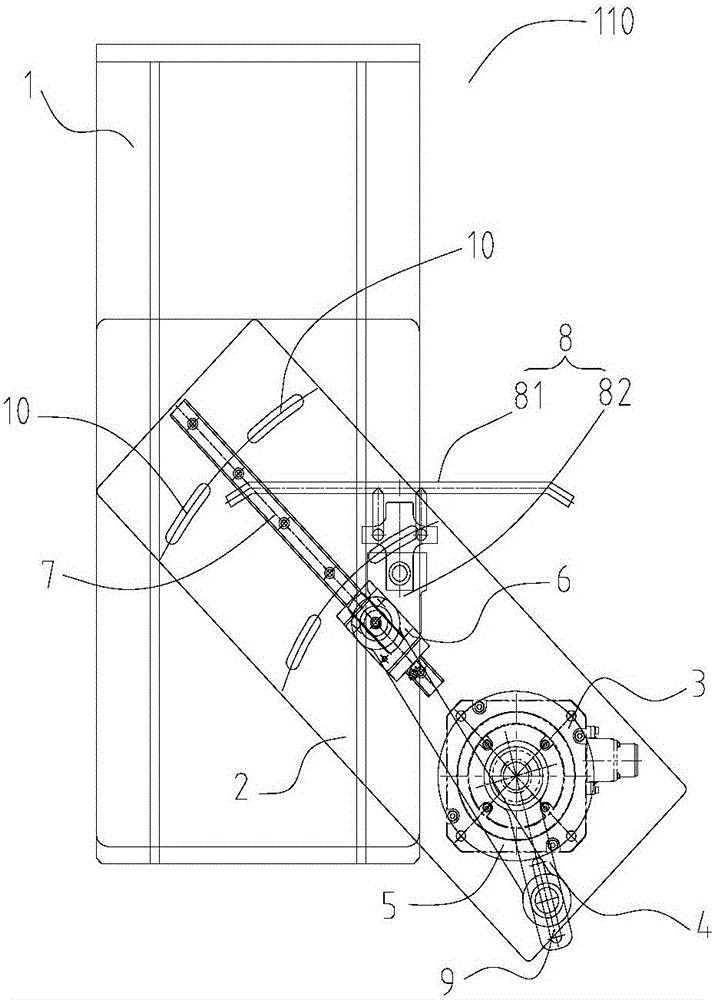

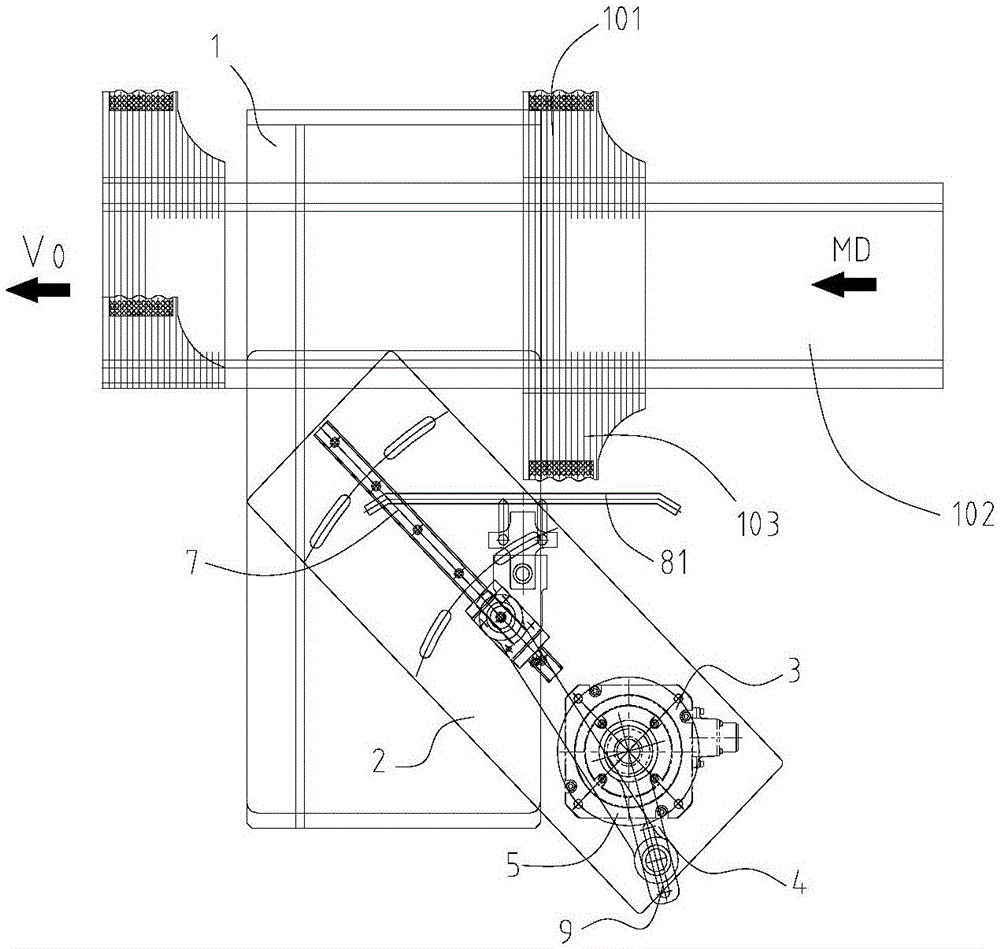

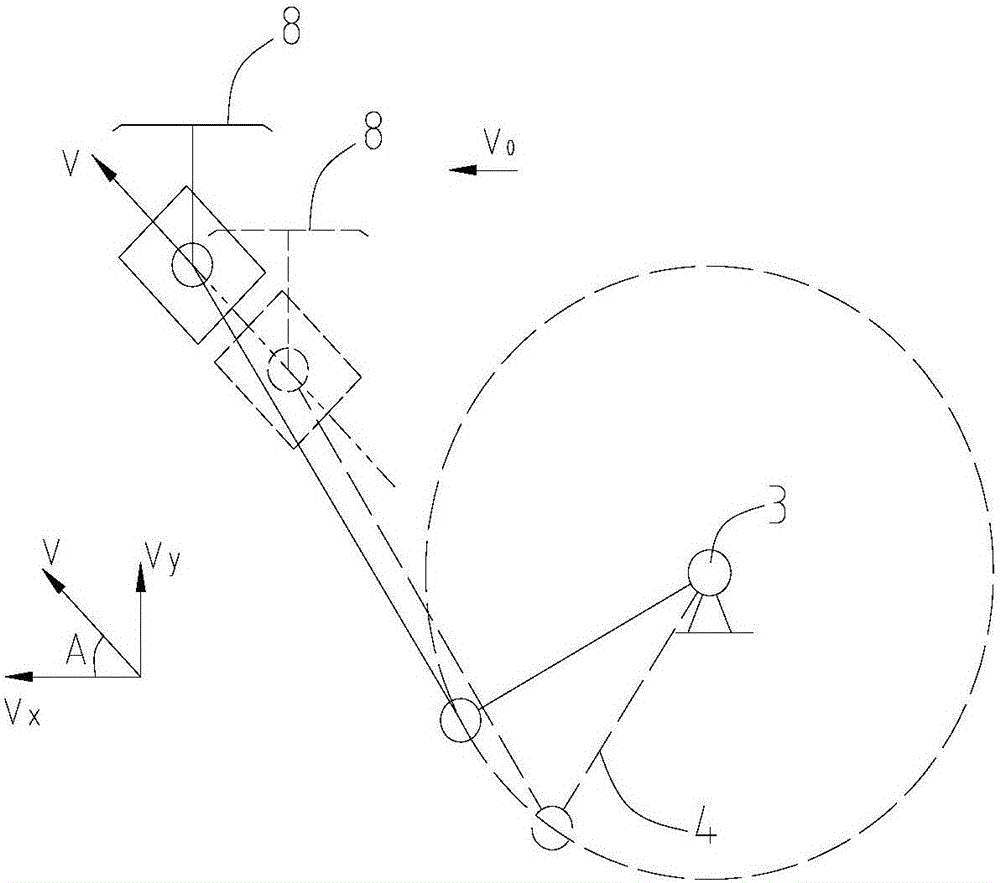

[0017] Please also refer to Figures 1 to 3 , a material wrapping device 110 for wrapping the side wings 103 of the elastic waist 101 during the movement of the absorbent body 102 equipped with the elastic waist 101 along the conveying direction MD of the absorbent body 102 . The absorbent body 102 and the elastic waistband 101 have an equal conveying speed V in the conveying direction MD 0 .

[0018] The material wrapping device 110 includes a mounting plate 1 , a base plate 2 , a servo motor 3 , a crank 4 , a connecting rod 5 , a slider 6 , a slide rail 7 and a guide component 8 .

[0019] Wherein, the connection between the mounting plate 1 and the base plate 2 is provided with several waist holes 10 which are easy to adjust the inclination angle between the sliding rail 7 and the conveying direction MD of the absorbing main body 102 . The main shaft of the servo motor 3 is connected with the crank 4 , one end of the connecting rod 5 is connected with the crank 4 , and the o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap