Polycrystalline cubic boron nitride and production method therefor

A technology of cubic boron nitride and hexagonal boron nitride, which is applied in the field of cubic boron nitride polycrystal and its manufacturing, can solve the problems of sintered body strength and thermal diffusivity reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0070] [First Embodiment: Cubic Boron Nitride Polycrystal]

[0071] A cubic boron nitride polycrystal according to one embodiment of the present disclosure will be described.

[0072]

[0073] The cubic boron nitride polycrystal of the present disclosure is a cubic boron nitride polycrystal containing more than 98.5% by volume of cubic boron nitride, wherein the dislocation density of the cubic boron nitride is greater than 8×10 15 / m 2 The cubic boron nitride polycrystal contains a plurality of crystal grains, and the median diameter d50 of the circle-equivalent diameters of the plurality of crystal grains is not less than 0.1 μm and not more than 0.5 μm.

[0074] The cubic boron nitride polycrystal of the present disclosure is a sintered body, but usually the sintered body is mostly intended to contain a binder, so the term "polycrystal" is used in the present disclosure.

[0075] When the cubic boron nitride polycrystal of the present disclosure is used as a tool, especi

no. 2 approach

[0168] [Second Embodiment: Manufacturing Method of Cubic Boron Nitride Polycrystal]

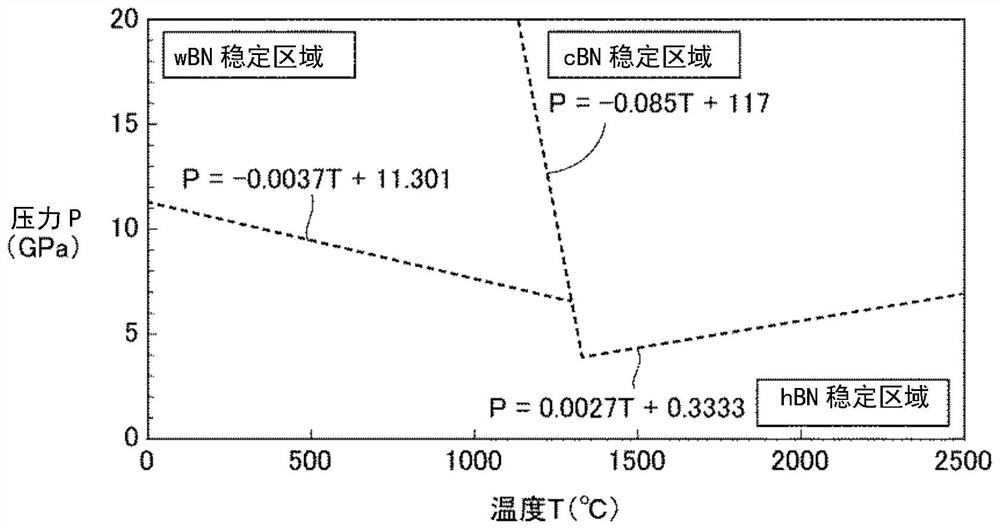

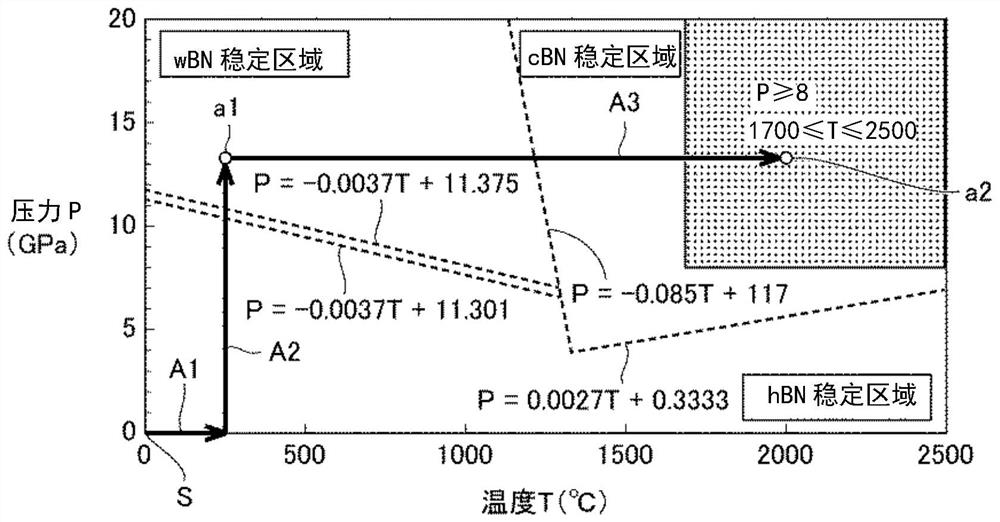

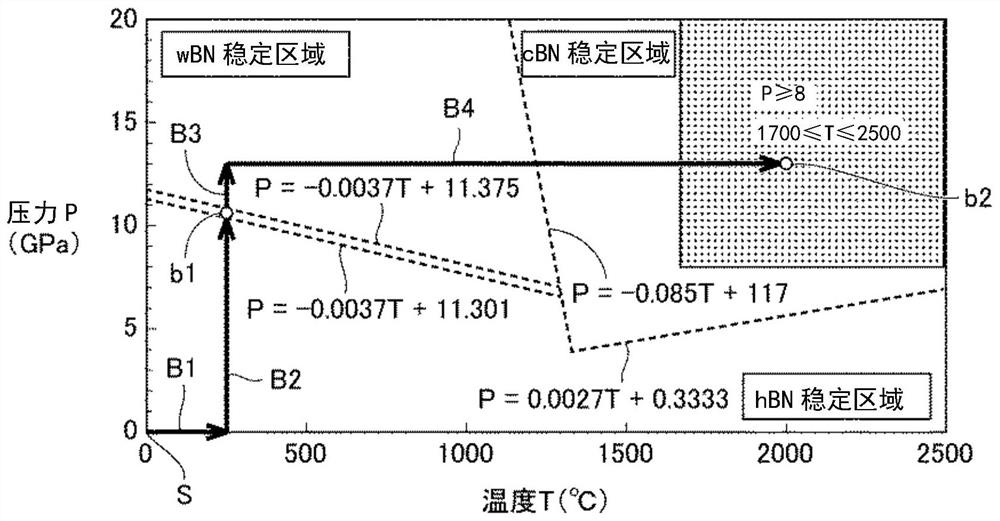

[0169] use Figure 1 to Figure 5 A method for producing the cubic boron nitride polycrystal of the present disclosure will be described. figure 1 is the pressure-temperature phase diagram of boron nitride. Figure 2 ~ Figure 4 It is a figure for demonstrating the manufacturing method of the cubic boron nitride polycrystal of this disclosure. Figure 5 It is a figure for demonstrating the conventional example of the manufacturing method of the cubic boron nitride polycrystal.

[0170] The method for producing a cubic boron nitride polycrystal of the present disclosure is the method for producing a cubic boron nitride polycrystal of the first embodiment. The manufacturing method of the cubic boron nitride polycrystal of the present disclosure includes: a first step of preparing hexagonal boron nitride powder (hereinafter, also referred to as "first step"); passing the hexagonal boron nitride po

Embodiment 1

[0259] In Example 1, the production conditions of the cubic boron nitride polycrystal, the composition (composition, median grain size, and dislocation density) of the obtained cubic boron nitride polycrystal, and the use of The relationship between tool life in the case of high-load machining of difficult-to-cut materials performed with cubic boron nitride polycrystalline tools was investigated.

[0260]

[0261] Cubic boron nitride polycrystals of Sample 1-1 to Sample 9 were prepared according to the following procedure.

[0262] (first process)

[0263] 6 g of hexagonal boron nitride powder (“Denka boron nitride” (trade name) manufactured by Denka Corporation, particle diameter: 5 μm) was prepared. The above-mentioned hexagonal boron nitride powder was filled into a capsule made of molybdenum, and set in an ultra-high pressure and high temperature generator.

[0264] (second process and third process)

[0265] [Sample 1-1, Sample 1-3, Sample 2-2, Sample 3-2, Sample 4 to S

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dislocation density | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap