Photovoltaic assembly outdoor testing device and method of programmable compensation design

A photovoltaic module and testing device technology, applied in the field of testing, can solve the problems of insufficient power supply, short-circuit current of photovoltaic cells, large volume and power of four-quadrant power supply, etc., to achieve reliable long-term volt-ampere characteristic testing, fast and efficient Volt-ampere characteristic curve test, power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

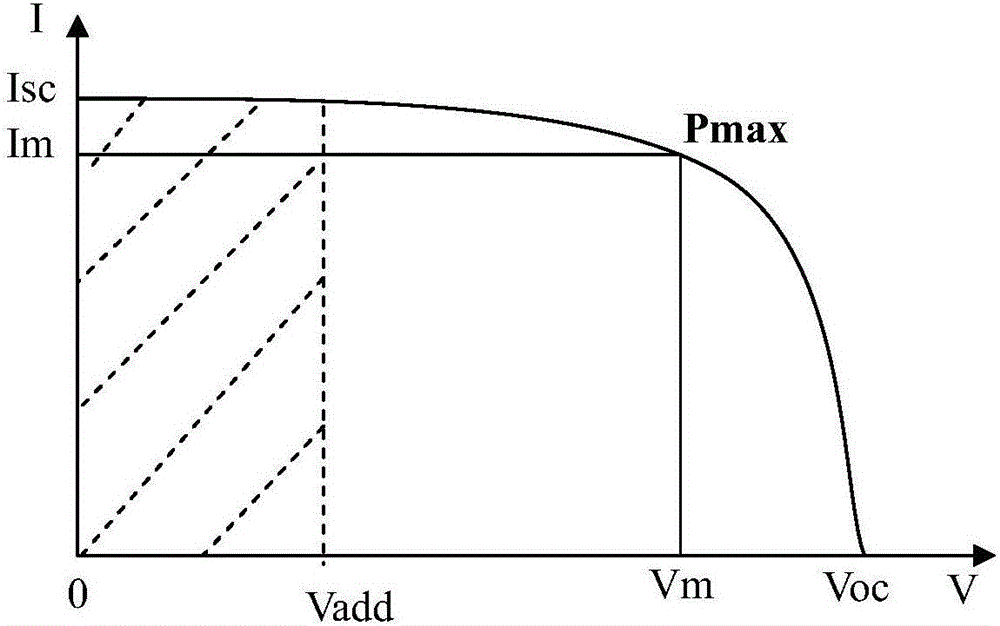

[0031] Such as figure 1 As shown in the middle shaded area, Vadd represents the minimum voltage drop in the photovoltaic module test circuit. If no compensation power supply is added, when the test load gradually decreases and the photovoltaic module voltage drops to the Vadd position shown in the figure, the battery voltage will follow due to the increase in current. The photovoltaic cell cannot output current if it fails to meet the driving voltage requirements at both ends of the test circuit load. The magnitude of the Vadd voltage is related to the short-circuit current of the photovoltaic module and the minimum resistance of the test circuit. The present invention strictly controls the loop resistance through the selection and design of the load, but considering the current status of device technology, the minimum loop resistance will reach more than 200mΩ, considering the design of about double the margin, the test loop resistance is planned to reach 400mΩ. The short-circu

Embodiment 2

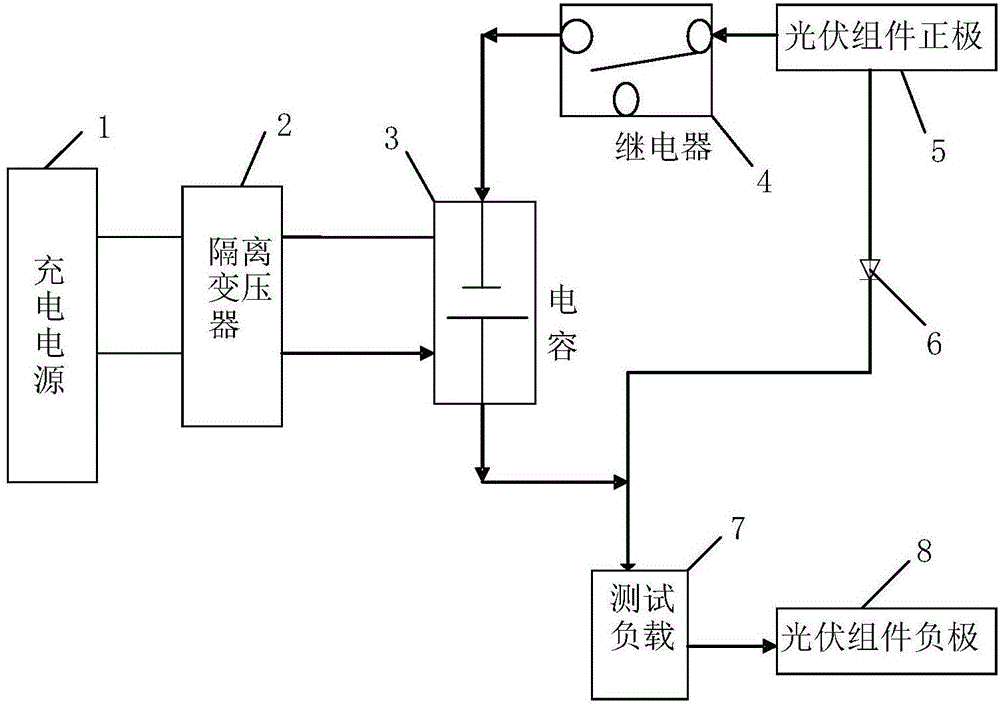

[0035] On the basis of the above-mentioned embodiments, the present invention also mentions a method for outdoor testing of photovoltaic modules. Before the test, the value of the test load resistance 7 is adjusted to the maximum, and the relay 4 is disconnected to separate the compensation power supply capacitor 3 from the photovoltaic module under test. The capacitor is fully charged by the charging power supply 1, and the isolation transformer 2 plays the role of isolation. When the test starts, the charging power supply 1 is disconnected, and the test load 7 is adjusted to make its resistance change from large to small, then the output current of the photovoltaic module increases and the output voltage decreases. When the output voltage is lower than the set voltage Vadd, the relay 4 is turned on, the compensation power supply capacitor 3 starts to discharge, and maintains until the output voltage of the photovoltaic module is 0V, and the relay 4 is disconnected to complete th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap