Carbon-based resistive flexible pressure sensor

A pressure sensor and resistive technology, which is applied in the field of new sensors, can solve the problems that cannot meet the needs of high-frequency pressure signal measurement, and achieve the effects of high sensitivity, good stability and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

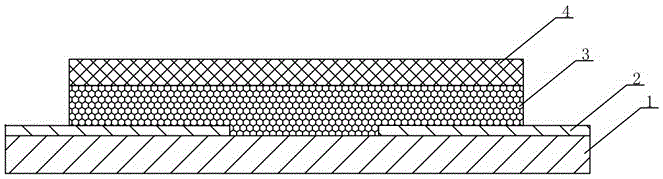

[0041] refer to figure 1 , which is a film structure of the present invention as a whole, including a four-layer structure film, a flexible polyimide film layer 1, a silver electrode layer 2, a composite film layer 3 of flexible graphene and graphene oxide, and a graphene oxide film insulating protective layer 4 . The fabrication and assembly process of the present invention is as follows:

[0042] Firstly, the substrate of the pressure sensor is made: through mature ion exchange and inkjet printing technology, a 2μm thick silver electrode layer is grown on both ends of a 50μm thick clean polyimide film.

[0043]Then make the upper functional layer of the pressure sensor: mix graphene and graphene oxide at a ratio of 5:1, and prepare a suspension with a concentration of 1.5mg / ml, and prepare a pure graphene oxide suspension at the same time solution, the concentration is 1.5mg / ml. Then the two kinds of suspensions were continuously suction-filtered by sequential vacuum fil

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap