Rubber composition with low rolling resistance and vulcanized rubber and preparation method and application thereof

A technology of rubber composition and low rolling resistance, applied in rolling resistance optimization, transportation and packaging, special tires, etc., can solve problems such as complex process, high cost, and difficulty in industrial production, and achieve high wet skid resistance and low rolling resistance Resistance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

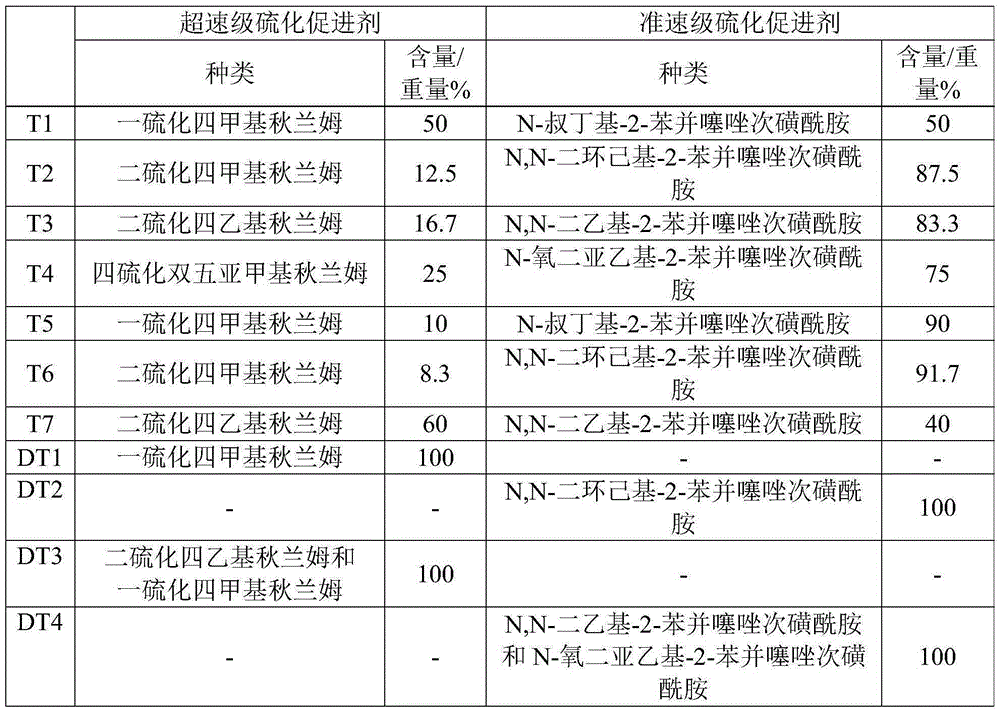

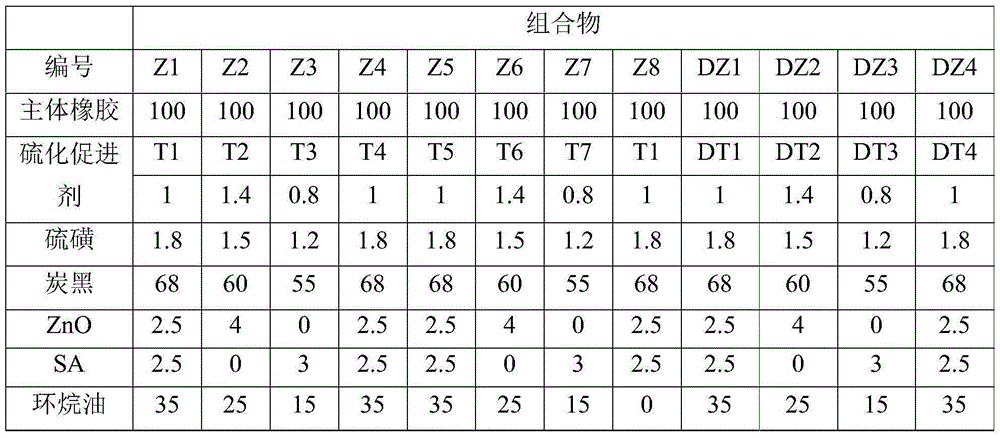

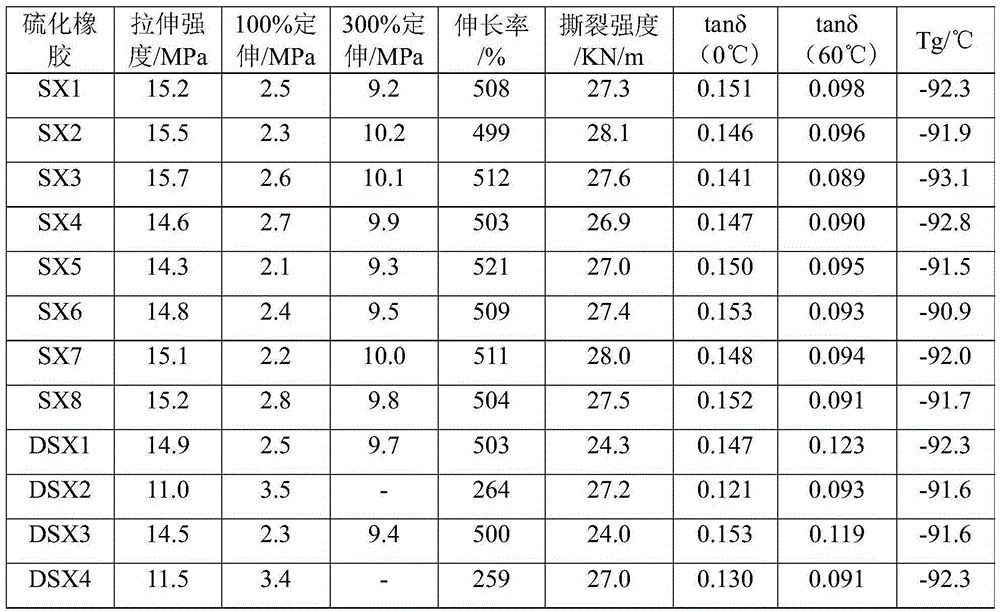

Method used

Image

Examples

preparation example Construction

[0035] In the method for preparing vulcanized rubber provided by the present invention, the type and content of each component in the rubber composition can be reasonably selected according to the above, which will not be repeated here.

[0036] In the method for preparing vulcanized rubber provided by the present invention, the mixing method and conditions can be selected conventionally in the art. For example, the mixing can be performed in an open mill or an internal mixer.

[0037] Preferably, the vulcanization conditions include a vulcanization temperature of 140-160° C., a vulcanization pressure of 5-15 MPa, and a vulcanization time of 10-50 minutes.

[0038] According to a preferred embodiment, the method for preparing vulcanized rubber can be carried out as follows:

[0039](1) In the internal mixer, add the main rubber, and mix at the initial temperature of 50-80°C for 30-60s;

[0040] (2) Add 1 / 2-3 / 4 weight of all reinforcing agents and all activators and mix for

Embodiment 1

[0065] The preparation method of the vulcanized rubber SX1 of the present embodiment is carried out as follows:

[0066] (1) In an internal mixer, at a speed of 90rpm, knead nickel-based butadiene rubber BR9000 at an initial temperature of 80°C for 30s;

[0067] (2) Add the reinforcing agent accounting for 3 / 4 of the weight of the total reinforcing agent and all the activators and knead for 2.5 minutes;

[0068] (3) Add the remaining reinforcing agent, the remaining components in the rubber composition Z1 except for the vulcanizing agent and the vulcanization accelerator, and after the temperature of the rubber material reaches 150° C., mix at this temperature for 6 minutes and then unload the rubber material;

[0069] (4) Pass the rubber material three times on an open mill with a roller distance of 5mm and a roller temperature of 50±5°C, and park the obtained mixed rubber for 4h;

[0070] (5) Mix the compound rubber obtained in step (4) with the vulcanizing agent and the vul

Embodiment 2

[0075] The preparation method of the vulcanized rubber SX2 of the present embodiment is carried out as follows:

[0076] (1) In the internal mixer, under the rotating speed of 90rpm, the rare earth butadiene rubber CB24 was mixed at the initial temperature of 60°C for 45s;

[0077] (2) adding the reinforcing agent accounting for 3 / 5 of the weight of the total reinforcing agent and all the activators and mixing for 2 minutes;

[0078] (3) Add the remaining reinforcing agent, the remaining components in the rubber composition Z2 except the vulcanizing agent and the vulcanization accelerator, and unload the rubber compound when the temperature of the rubber compound reaches 170°C;

[0079] (4) Pass the rubber material through an open mill with a roller distance of 5mm and a roller temperature of 50±5°C for three times, and park the obtained mixed rubber for 5h;

[0080] (5) mixing the mixed rubber obtained in step (4) with a vulcanizing agent and a vulcanization accelerator at an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap