Semi-automatic lifting device convenient for moving battery into battery rack and control method of semi-automatic lifting device

A lifting device and control method technology, applied to lifting devices, lifting frames, lifting equipment safety devices, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effects of reducing process time, reducing friction, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

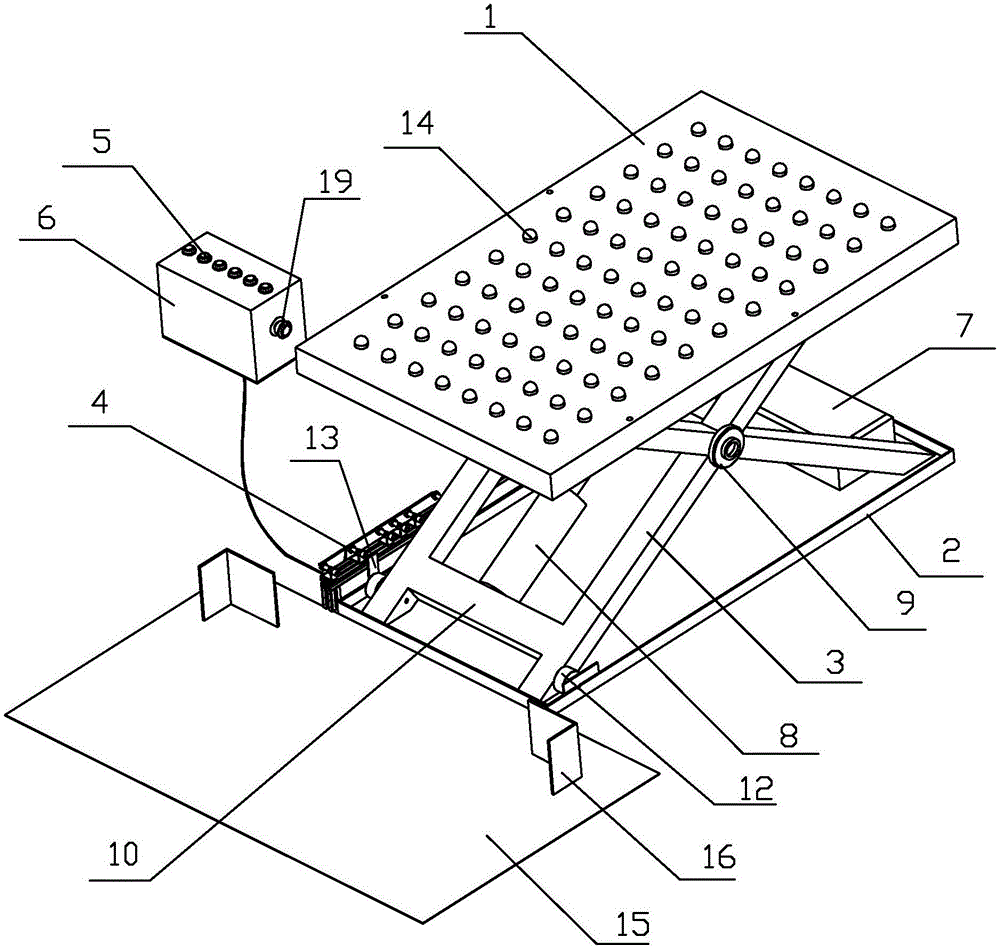

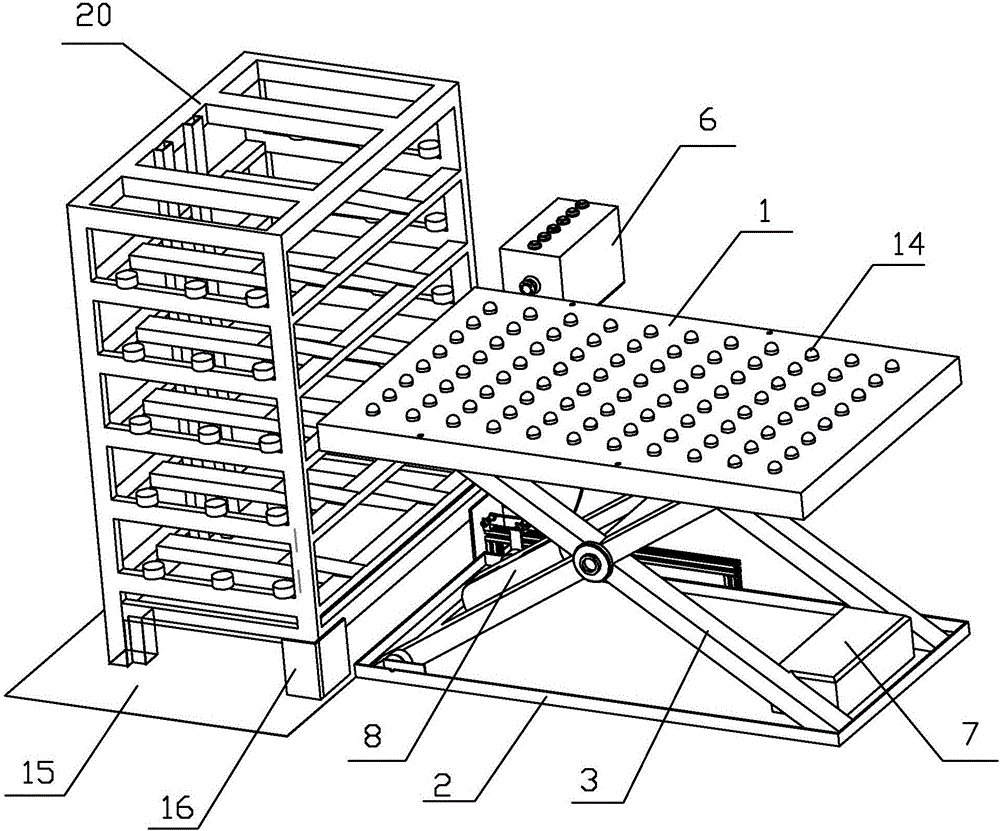

[0019] Embodiment: the semi-automatic lifting device that is convenient to the battery of the present embodiment is moved into the battery rack, as shown in Fig. 1, figure 2As shown, it includes a lifting platform 1, a bottom frame 2, a support 3 cross-connected by a rotating shaft, a driving mechanism, six proximity sensors 4 and an electrical control cabinet 6 with six control buttons 5 installed. A plurality of rolling bulls-eye universal balls 14 are embedded on the top surface of the lifting platform 1 , and the bulls-eye universal balls 14 are arranged in a matrix structure and cover the entire lifting platform 1 . The bottom of the support 3 is located in the bottom frame 2, the front foot on the top of the support 3 is slidingly connected to the slide rail on the back of the lifting platform 1 through pulleys, the rear foot on the top of the support 3 is fixed to the back of the lifting platform 1, and the rear foot at the bottom of the support 3 is connected to the botto

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap