Cyclone dust collector used in innocent treatment process of diseased animals

A technology of harmless treatment and cyclone dust collector, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc., can solve the problems of low dust removal efficiency, equipment failure, pipeline blockage, etc., and achieve improved treatment Efficiency, improve dust removal efficiency, and prevent pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

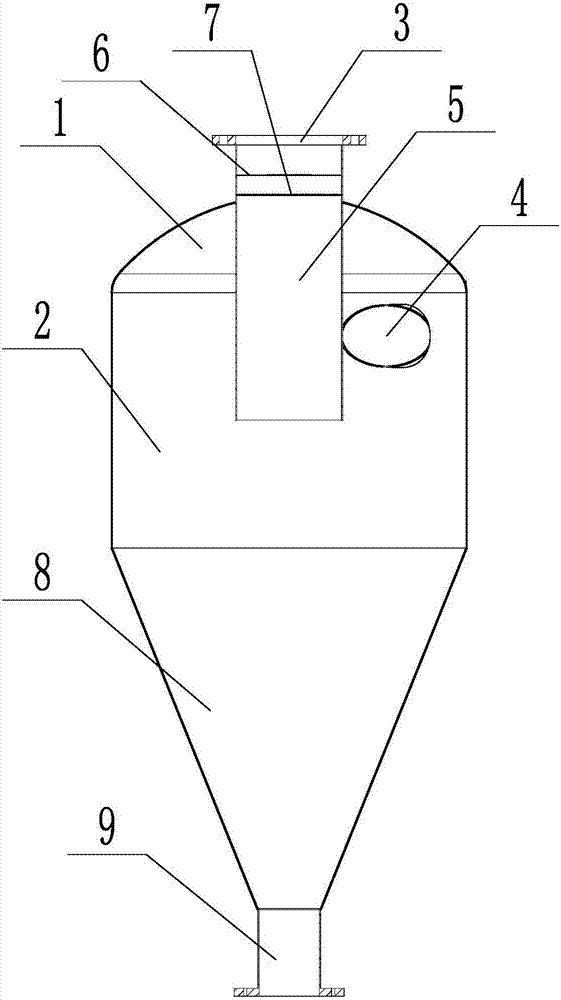

[0010] Such as figure 1 As shown, the present invention includes a sealing head 1, a cylinder body 2, an air outlet 3 and an air inlet 4, and is characterized in that an air inlet 4 is arranged on the outer wall of the cylinder body 2, and the upper end of the cylinder body 2 is connected to the The head 1 is connected, the top of the head 1 is provided with a pipeline 5 that runs through the cylinder 2, the upper end of the pipeline 5 is provided with an air inlet 4, and the inner wall of the pipeline 5 is provided with a fine mesh 7, so The bottom of the fine filter 7 is provided with a coarse filter 7 close to the inner wall of the pipeline 5, the bottom of the cylinder 2 is connected to the conical cylinder 8, and the bottom of the conical cylinder 8 is provided with a dust collection port 9 .

[0011] Working principle: The high-temperature steam containing material dust particles is introduced into the cylinder 2 of the dust collector from the air inlet 4, and a downward r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap