Pulse bag-type dust collector on-line detection device

A bag-type dust collector and detection device technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve data management and adjustment, dust removal box wind speed, dust concentration can not be detected, affect the pulse problems such as the service life of the bag filter to achieve the effect of improving the dust removal efficiency and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

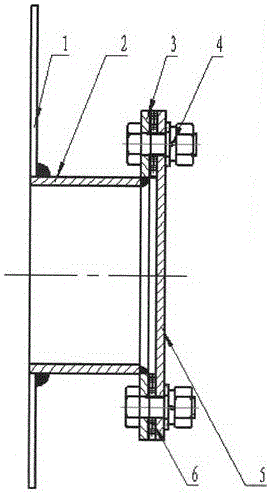

[0009] The embodiments are described in detail with reference to the above drawings, such as figure 1 As shown, one end of the steel pipe 2 protrudes into the interior of the dust collector box 1, and the joint between the two is welded. The other end of the steel pipe is equipped with a sealing ring 6 between the lower flange 3 and the upper flange 5 and is fastened with bolts 4. seal.

[0010] The steel pipe 2 is a hollow core, and at least two steel pipes extend into the inside of the dust collector box 1. The steel pipe is a detection path for detecting the wind speed and dust concentration inside the dust removal box. One steel pipe is located at the air inlet of the dust removal box, and the other A steel pipe is located at the air outlet of the dust box.

[0011] When the dust collector is working, remove the bolts, upper and lower flanges and sealing rings, and extend the anemometer and concentration detector from the steel pipe into the dust removal box. The wind spe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap