Automatic lifting protective guard used at highway-railway intersection

A technology of automatic lifting and railway entrance, applied in the direction of the manipulation of highway barriers, etc., can solve the problems of increased railway construction costs, unsuitable road barriers, and high cost maintenance costs, so as to reduce construction costs, avoid railway construction costs, and avoid manpower. The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

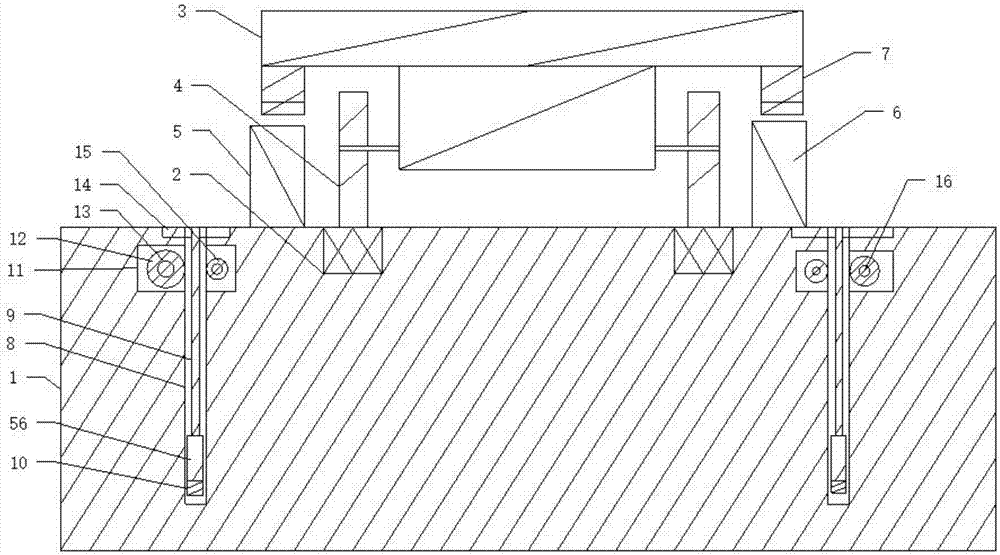

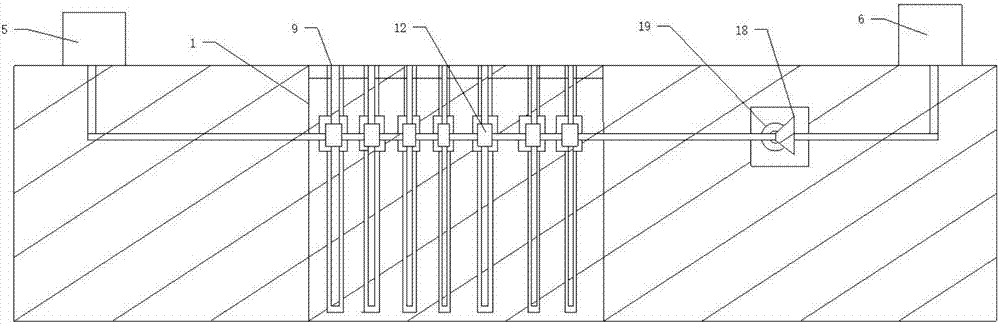

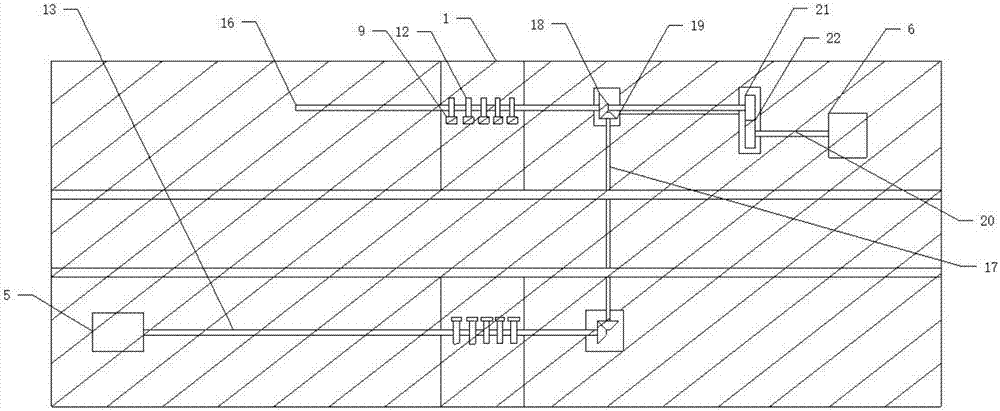

[0033] Such as Figure 1 to Figure 11 Shown, a kind of highway railroad crossing automatic lifting guardrail, comprises subgrade 1, and described subgrade 1 is provided with two corresponding tracks 2, and described track 2 is provided with a train 3, and described train 3 is provided with The wheels 4 rotating on the track 2, the two sides of the track 2 respectively include a row of first sliding holes 8 arranged on the roadbed 1, and a sliding protective railing 9 is respectively arranged in the first sliding holes 8 The two sides of the track 2 are respectively provided with a first inner chamber 11 correspondingly connected with the first slide holes 8 side by side, and the two sides of the track 2 are respectively provided with a First rotating shaft 13 and a second rotating shaft 16, described first rotating shaft 13 and described second rotating shaft 16 are respectively provided with a drive gear 12 that drives described protective railing 9 to slide, described protectiv

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap