Microbial dust suppressant and application thereof

A technology of microorganisms and dust suppressants, applied in the field of environmental science, can solve problems such as unsuitable for large-scale promotion and application, complicated operation, secondary pollution, etc., and achieve simple and convenient application methods, good ecological compatibility, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare 1kg of microbial dust suppressant according to 2.0wt% of microbial powder, 29.0wt% of calcium source, and 69.0wt% of deionized water:

[0033] (1) First, dissolve 20g of microbial powder in 690g of deionized water, mix well and dissolve;

[0034] (2) Next, obtain the microbial dust suppressant by dissolving 290g calcium chloride in the above-mentioned microbial bacterium liquid;

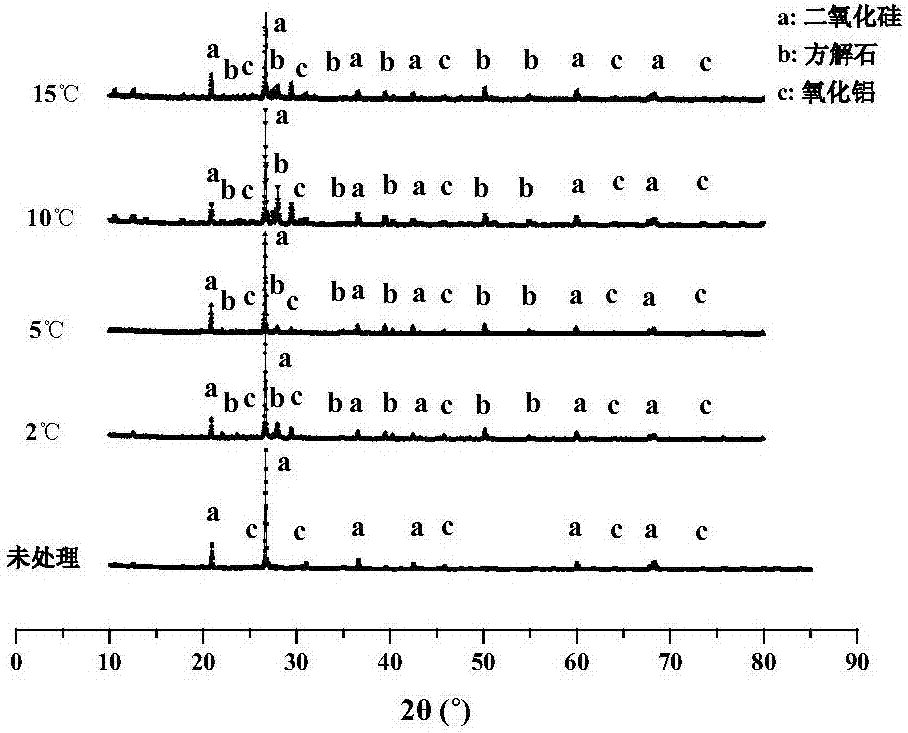

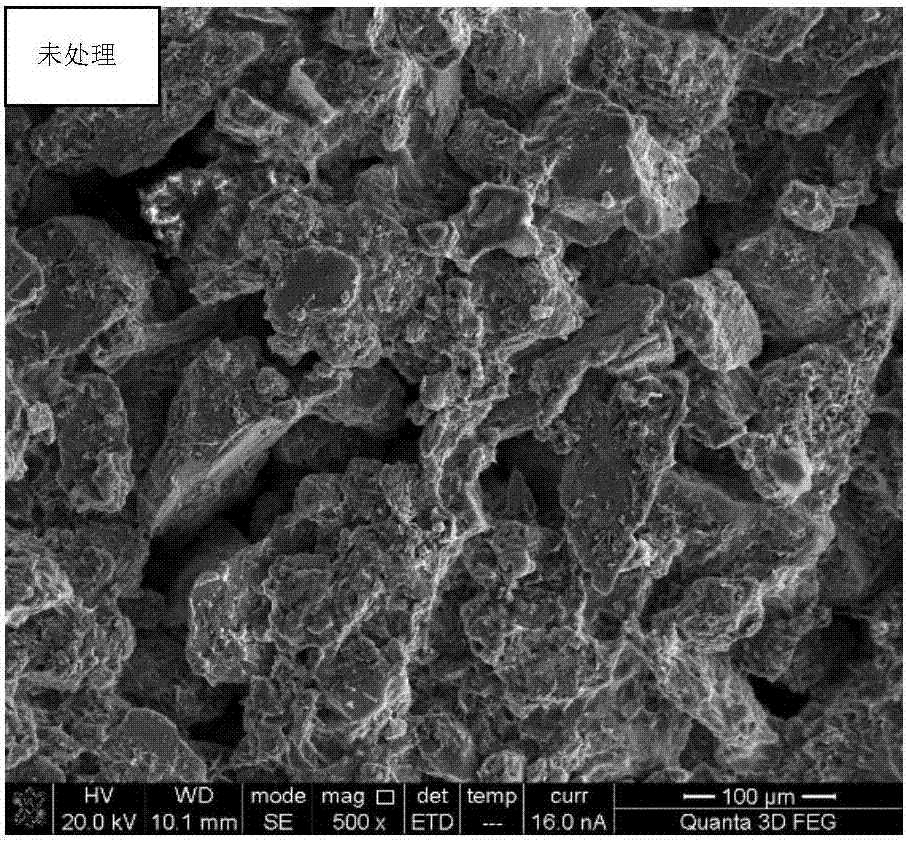

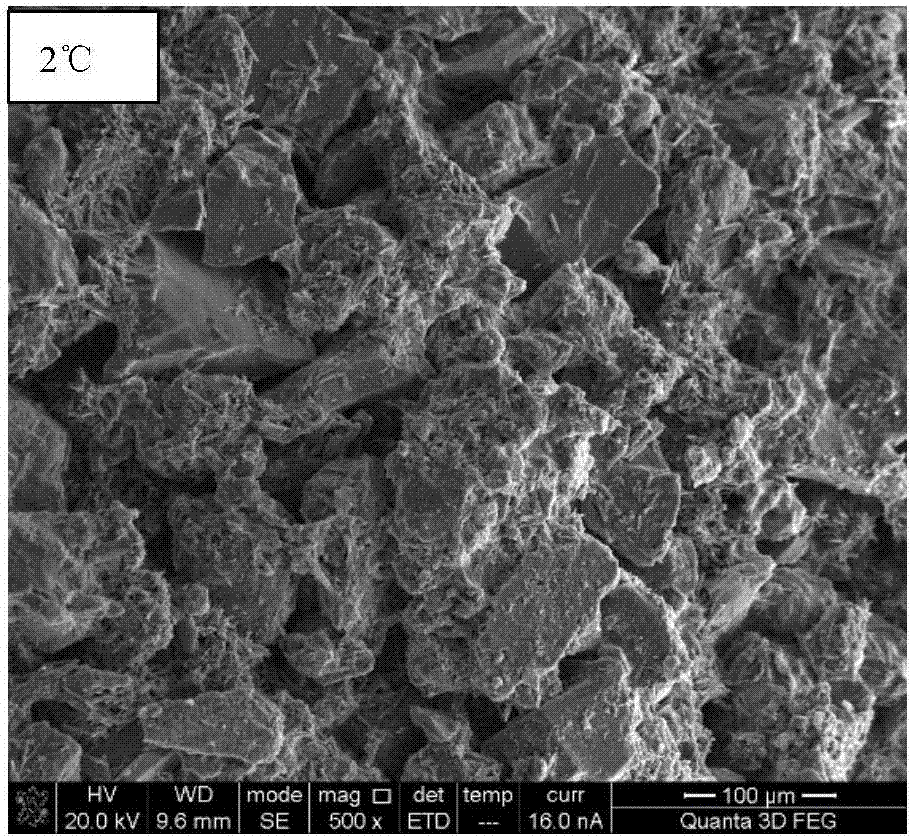

[0035] Spray the prepared microbial dust suppressant evenly on the 0.69m 2 Sandy surface. After the treatment, the dust is placed under atmospheric conditions for 7 days, the atmospheric temperature is 2°C, and the relative humidity is 50% to 70%, and then XRD, SEM, strength and wind erosion resistance tests are carried out.

Embodiment 2

[0037] Prepare 1kg of microbial dust suppressant according to 3.0wt% of microbial powder, 30.0wt% of calcium source, and 67.0wt% of deionized water:

[0038] (1) First, dissolve 30g of microbial powder in 670g of deionized water, mix well and dissolve;

[0039] (2) Next, obtain the microbial dust suppressant by dissolving 300g calcium chloride in the above-mentioned microbial bacterium liquid;

[0040] Spray the prepared microbial dust suppressant evenly on the 0.69m at an ambient temperature of 5°C 2 Sandy surface. After the treatment, the dust is placed under atmospheric conditions for 7 days, the atmospheric temperature is 5°C, and the relative humidity is 50% to 70%, and then XRD, SEM, strength and wind erosion resistance tests are carried out.

Embodiment 3

[0042] Prepare 1kg of microbial dust suppressant according to 2.5wt% of microbial powder, 29.0wt% of calcium source, and 68.5wt% of deionized water:

[0043] (1) First, dissolve 25g of microbial powder in 685g of deionized water, mix well and dissolve;

[0044] (2) Next, obtain the microbial dust suppressant by dissolving 290g calcium chloride in the above-mentioned microbial bacterium liquid;

[0045] Spray the prepared microbial dust suppressant evenly on the 0.69m at an ambient temperature of 10°C 2 Sandy surface. After the treatment, the dust is placed under atmospheric conditions for 7 days, the atmospheric temperature is 10°C, and the relative humidity is 50% to 70%, and then XRD, SEM, strength and wind erosion resistance tests are carried out.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap