Aluminum phosphate sol and preparation method thereof

A technology of aluminum phosphate sol and phosphate, which is applied in chemical instruments and methods, phosphorus compounds, petroleum industry, etc., can solve the problems of equipment corrosion environment, environmental pollution, pollution, etc., and achieve improved peptization depth, improved wear resistance, The effect of decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

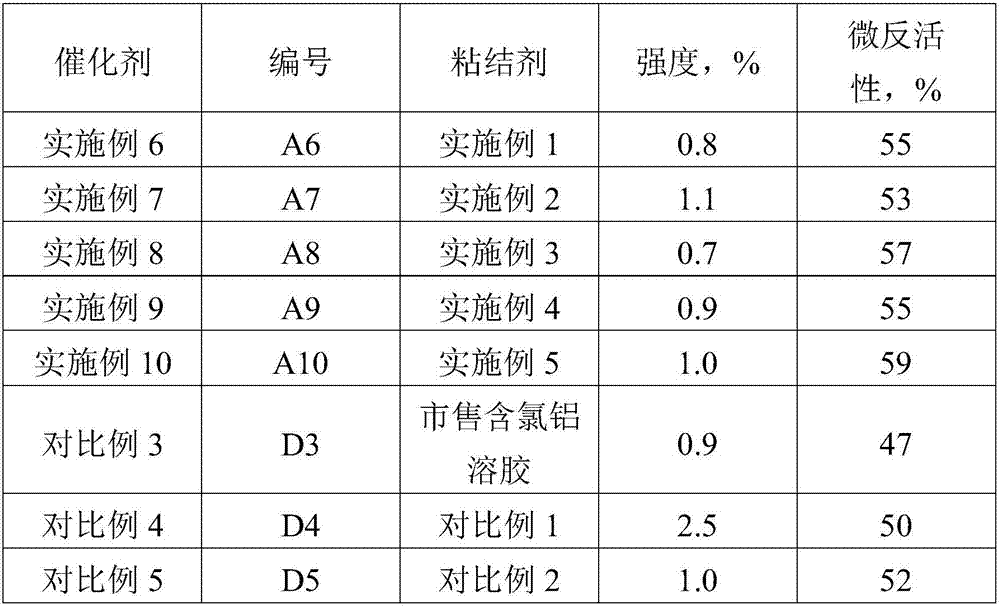

Examples

Embodiment 1

[0030]Add 2540 grams of deionized water, 1156 grams of pseudo-boehmite, 27 grams of ammonium dihydrogen citrate reagent in the reaction kettle, stir for 15 minutes, let stand for 4 hours, then stir, add 223 grams of concentrated phosphoric acid, stir for 20 minutes, The obtained sample is recorded as A1, and its Al 2 o 3 is 22.3% by weight, ammonium dihydrogen citrate is 0.6% by weight, and phosphorus is 1.6% by weight.

Embodiment 2

[0032] Add 2530 grams of deionized water, 882 grams of pseudoboehmite, and 712 grams of magnesium acetate reagent in the reaction kettle, stir for 25 minutes, let stand for 20 hours, then stir and add 846 grams of diammonium hydrogen phosphate, stir for 10 minutes and then add 2185 grams of concentrated phosphoric acid was stirred for 30 minutes, and the sample was recorded as A2, and its Al 2 o 3 is 10.6% by weight, magnesium acetate is 9.95% by weight, and phosphorus is 13% by weight.

Embodiment 3

[0034] Add 2530 grams of deionized water, 5083 grams of pseudoboehmite, and 600 grams of ammonium acetate reagent in the reaction kettle, stir for 30 minutes, stand still for 13 hours, then stir, add 1087 grams of ammonium phosphate and 2672 grams of concentrated phosphoric acid, and stir for 20 minutes , that is, the sample is recorded as A3, and its Al 2 o 3 is 35.4% by weight, ammonium acetate is 5.0% by weight, and phosphorus is 8.5% by weight.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap