A kind of multi-color TPO automobile interior material and preparation method thereof

A technology for automotive interior and coating materials, applied in the field of multi-color TPO automotive interior materials and their preparation, can solve problems such as monotony, not meeting the personalized requirements of young people's interiors, etc., and achieves good scratch resistance, The effect of good hand feeling and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

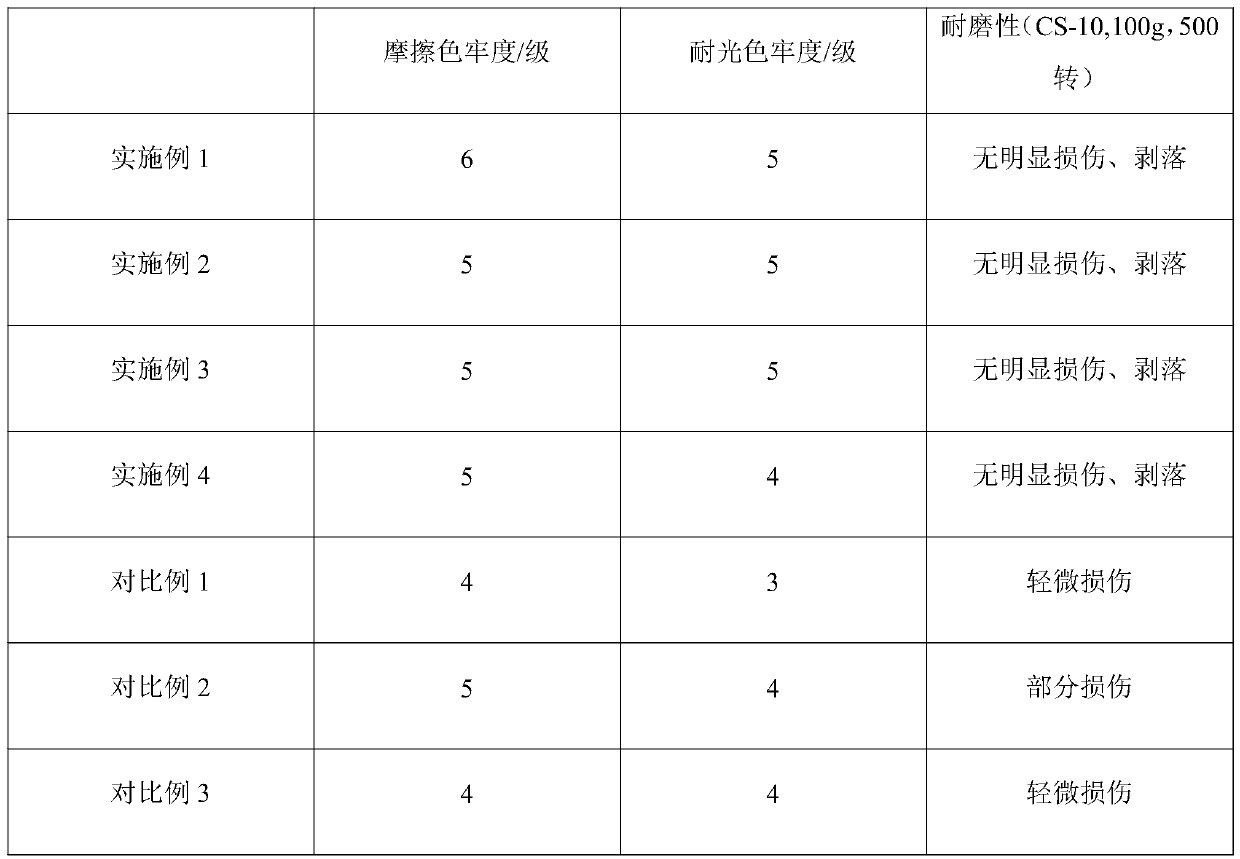

Examples

Example Embodiment

[0028] Example 1

[0029] A multi-color TPO automotive interior material, which sequentially includes a polyolefin sponge layer, a multi-color TPO skin layer and a water-based polyurethane coating from bottom to top; the multi-color TPO skin layer is composed of at least two monochromatic TPO skins. Each single color TPO skin includes the following components in parts by weight: 30 parts of high-density polyethylene, 30 parts of polypropylene, 8 parts of ethylene-acrylic acid copolymer, 40 parts of EPDM rubber, rosin resin 18 parts, 5 parts of wollastonite, 3 parts of color masterbatch, 1 part of hindered amine, 1 part of hindered phenol, 1 part of magnesium hydroxide; the content of toner in the color masterbatch is 50wt%.

[0030] The preparation method of the above-mentioned multi-color TPO automotive interior materials includes the following steps:

[0031] 1) Preparation of single-color TPO skin: mix the components of the TPO skin layer uniformly, and then add them to the extruder

Example Embodiment

[0036] Example 2

[0037] A multi-color TPO automotive interior material, which sequentially includes a polyolefin sponge layer, a multi-color TPO skin layer and a water-based polyurethane coating from bottom to top; the multi-color TPO skin layer is composed of at least two monochromatic TPO skins. Each single color TPO skin includes the following components in parts by weight: 20 parts of high-density polyethylene, 40 parts of polypropylene, 5 parts of ethylene-acrylic acid copolymer, 50 parts of EPDM rubber, rosin resin 15 parts, 3 parts of talc powder, 6 parts of color masterbatch, 1 part of hindered amine, 2 parts of aromatic amine, 2 parts of aluminum hydroxide; the content of color powder in the color masterbatch is 45% by weight.

[0038] The preparation method of the above-mentioned multi-color TPO automotive interior materials includes the following steps:

[0039] 1) Preparation of single-color TPO skin: mix the components in the TPO skin layer uniformly, enter the extruder

Example Embodiment

[0044] Example 3

[0045] A multi-color TPO automotive interior material, which sequentially includes a polyolefin sponge layer, a multi-color TPO skin layer and a water-based polyurethane coating from bottom to top; the multi-color TPO skin layer is composed of at least two monochromatic TPO skins. Each single-color TPO skin includes the following components in parts by weight: 40 parts of high-density polyethylene, 20 parts of polypropylene, 10 parts of ethylene-acrylic acid copolymer, 30 parts of EPDM rubber, terpene 20 parts of resin, 8 parts of barium sulfate, 2 parts of color masterbatch, 1 part of hindered amine, 3 parts of hindered phenol, 2 parts of red phosphorus; the content of toner in the color masterbatch is 45% by weight.

[0046] The preparation method of the above-mentioned multi-color TPO automotive interior materials includes the following steps:

[0047] 1) Preparation of single-color TPO skin: mix the components in the TPO skin layer uniformly, enter the extruder t

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap