Analysis method of medium and short chain inulin based on acid hydrolysis

An analysis method, the technology of short-chain inulin, applied in the field of chemical analysis, can solve the problems of environmental pollution, hydrolysis, difficult recovery, etc., and achieve the effect of high reaction efficiency, high precision, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

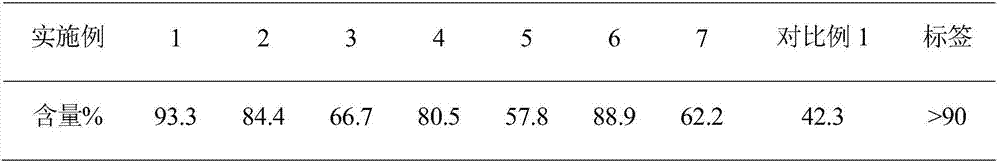

[0038] Example 1:

[0039] A method for analyzing short- and medium-chain inulin based on acid hydrolysis, including the following steps:

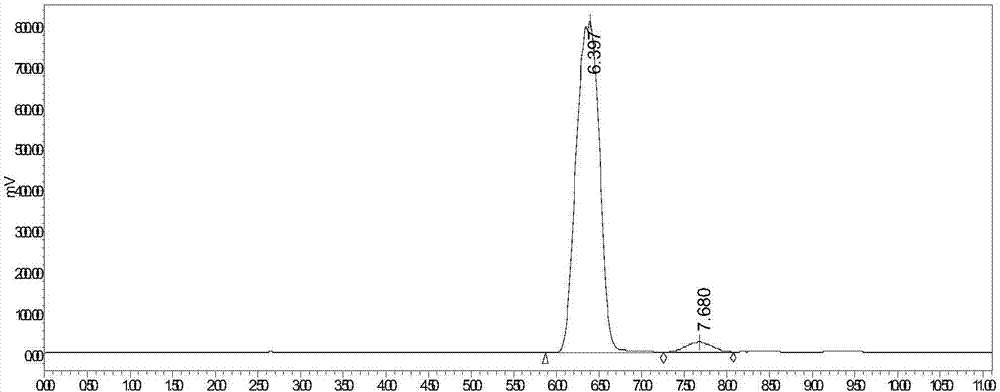

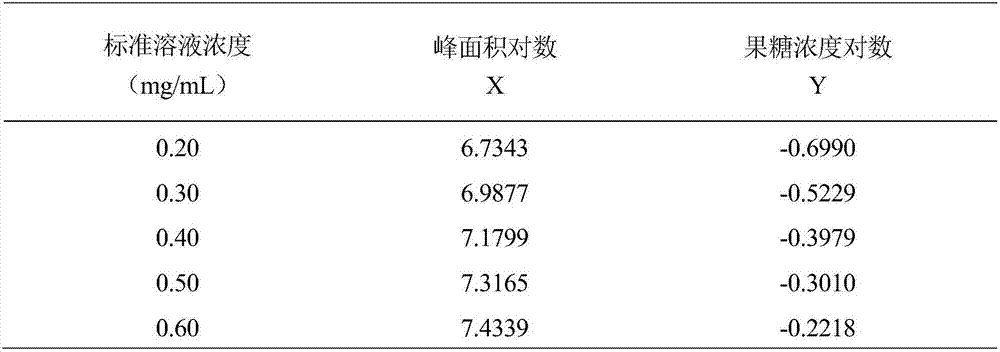

[0040] 1. Preparation of fructose standard solution: configure fructose standard (purity 99%) into a gradient solution of 0.20-0.60 mg / mL to be tested. Draw a standard curve with the concentration of fructose as the abscissa and the peak area of the liquid phase as the ordinate.

[0041] 2. Acid hydrolysis of inulin: Weigh 4.5 mg of short- and medium-chain inulin extract into an ampoule, add 3 mL of trifluoroacetic acid TFA with a concentration of 1 mol / L, seal it with a blowtorch, and react at 90°C for 60 minutes to hydrolyze the sample complete.

[0042] 3. Deacidification of the hydrolyzed solution: transfer the hydrolyzed sample solution to a micro-rotating flask, add 20 mL of methanol, and rotate it for 20 minutes at 40°C and a speed of 250r / min to remove the residual trifluoroacetic acid in the hydrolysate. After the solution is evapo

Example Embodiment

[0044] Example 2:

[0045] A method for analyzing short- and medium-chain inulin based on acid hydrolysis, including the following steps:

[0046] 1. Preparation of fructose standard solution: same as Example 1.

[0047] 2. Acid hydrolysis of inulin: Weigh 4.5 mg of short- and medium-chain inulin extract into an ampoule, add 3 mL of trifluoroacetic acid TFA with a concentration of 0.5 mol / L, seal with a blowtorch, and react at 90°C for 60 minutes to make the sample The hydrolysis is complete.

[0048] 3. Deacidification of the hydrolyzed solution: transfer the hydrolyzed sample solution to a micro-rotating flask, add 15 mL of methanol, and spin-evaporate for 10 minutes at 40°C and a rotation speed of 200r / min to remove the residual trifluoroacetic acid in the hydrolysate. After the solution is evaporated to dryness, add 10mL of water to reconstitute it, and store at 4℃;

[0049] 4. HPLC-ELSD detection: same as Example 1.

Example Embodiment

[0050] Example 3:

[0051] A method for analyzing short- and medium-chain inulin based on acid hydrolysis, including the following steps:

[0052] 1. Preparation of fructose standard solution: same as Example 1.

[0053] 2. Acid hydrolysis of inulin: Weigh 4.5 mg of short- and medium-chain inulin extract into an ampoule, add 3 mL of trifluoroacetic acid TFA with a concentration of 1.5 mol / L, seal with a blowtorch, and react at 90°C for 60 minutes to make the sample The hydrolysis is complete.

[0054] 3. Deacidification of the hydrolyzed solution: transfer the hydrolyzed sample solution to a micro-rotating flask, add 30 mL of methanol, and rotate it for 30 minutes at 40°C and a speed of 300r / min to remove the residual trifluoroacetic acid in the hydrolysate. After the solution is evaporated to dryness, add 10mL of water to reconstitute it, and store at 4℃;

[0055] 4. HPLC-ELSD detection: same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap