System and method for reusing denitration catalyst regeneration wastewater in catalyst recovery process

A technology for denitrification catalysts and regenerated wastewater, applied in chemical instruments and methods, gaseous effluent wastewater treatment, water/sewage multi-stage treatment, etc., can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example

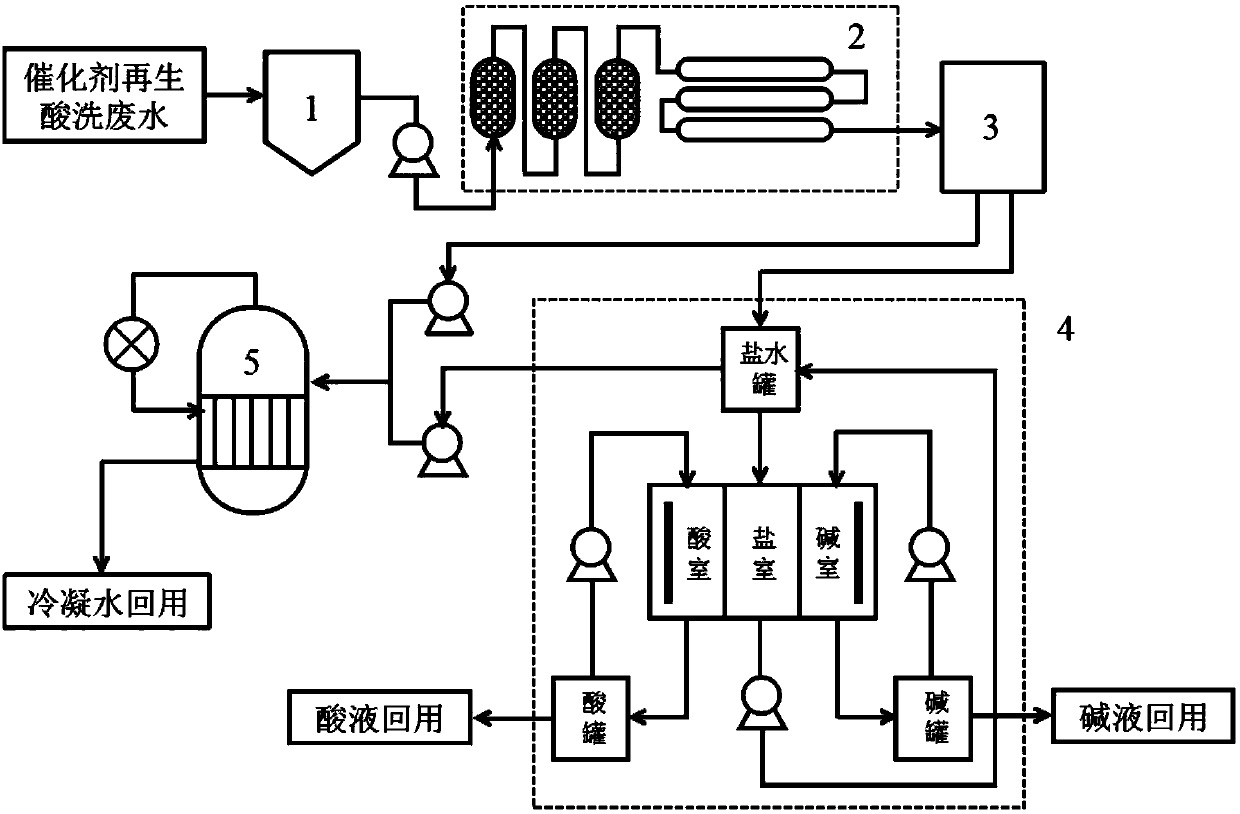

[0035] Such as figure 1 As shown, the system for reusing the denitrification catalyst regeneration wastewater in the catalyst recovery process in this embodiment mainly includes a coagulation sedimentation tank 1, a membrane concentration unit 2, a concentrated brine tank 3, a sodium sulfate electrolysis unit 4, and an evaporation crystallization unit 5.

[0036] The wastewater from the denitration catalyst pickling process section contains a certain amount of suspended solids, which are mainly ash residues and partially broken catalysts that have not been completely cleaned and removed in the previous steps. The pH value of the wastewater is about 1, and contains heavy metal ions such as vanadium and arsenic.

[0037] The pickling wastewater is discharged into the coagulation sedimentation tank 1, and a sodium hydroxide solution with a mass fraction of 40% is added through the sodium hydroxide dosing device to adjust the pH of the mixed solution to 7. A 10% mass fract

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap