Efficient and environment-friendly slime separating device

A separation device, an environmentally friendly technology, applied in solid separation, wet separation, chemical instruments and methods, etc., to prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

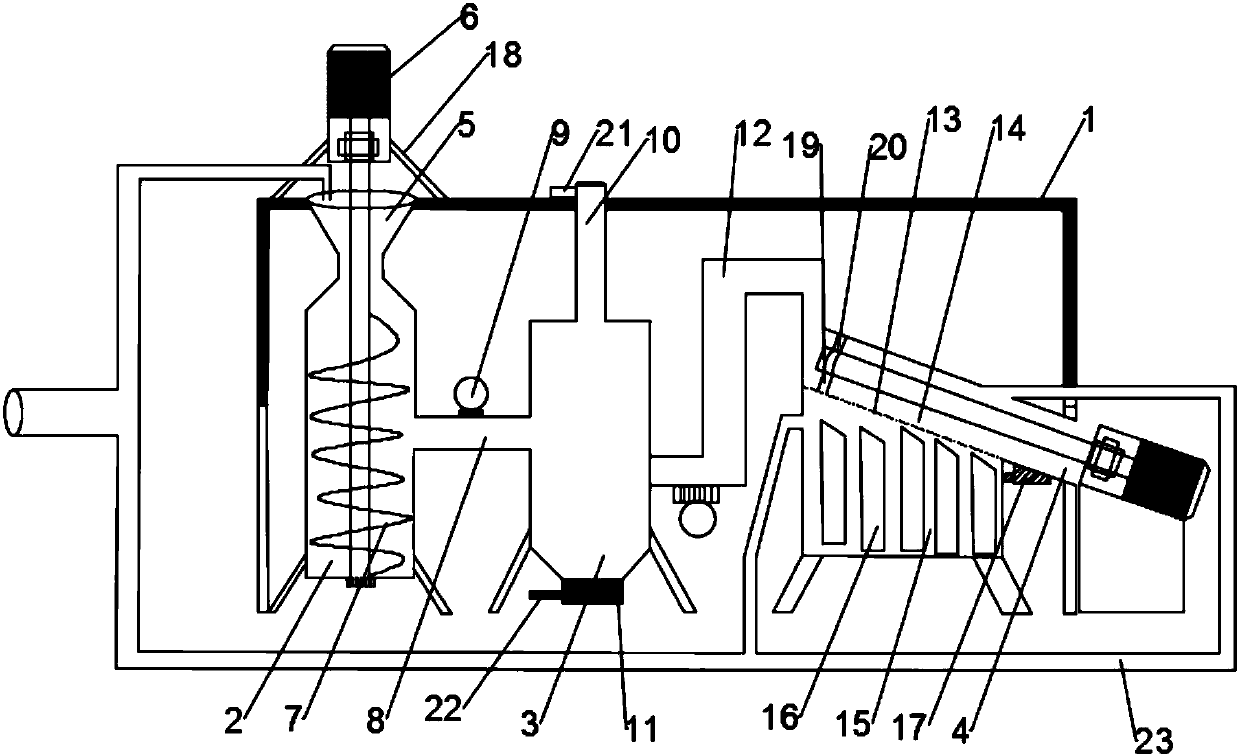

[0020] Examples:

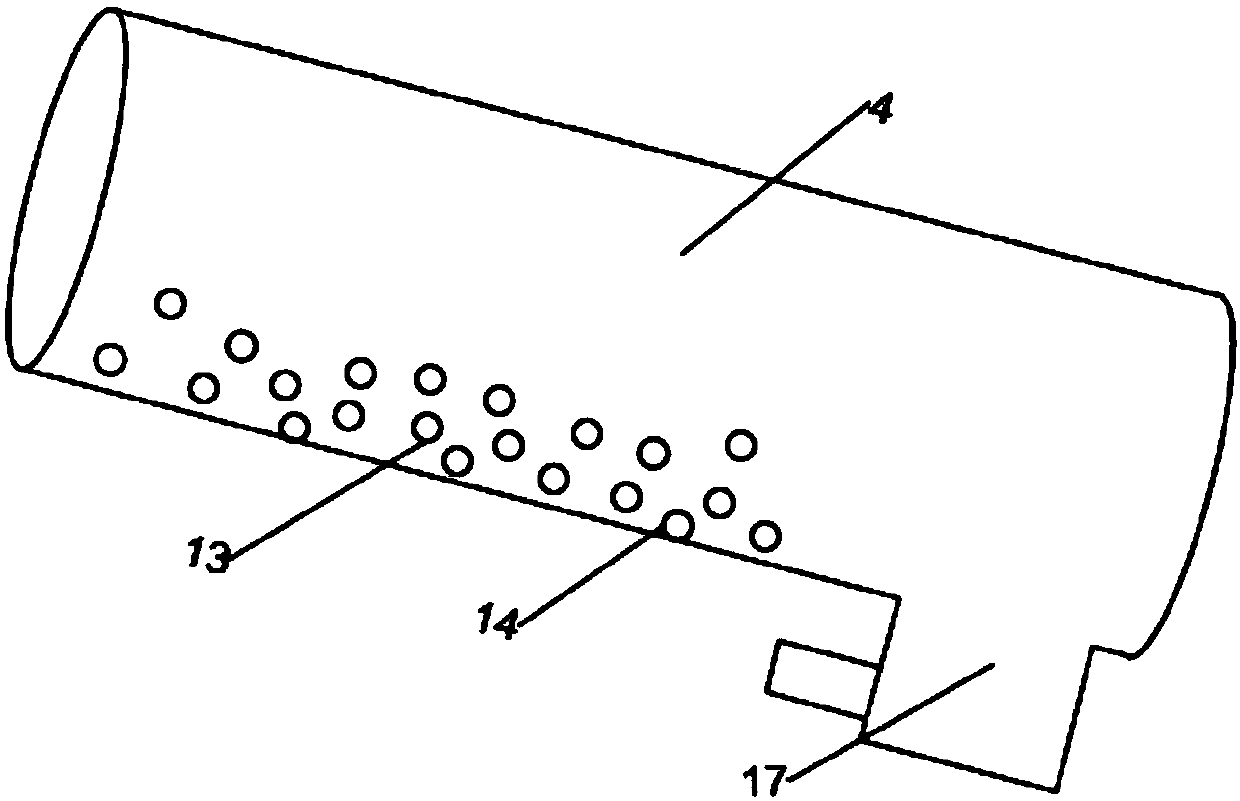

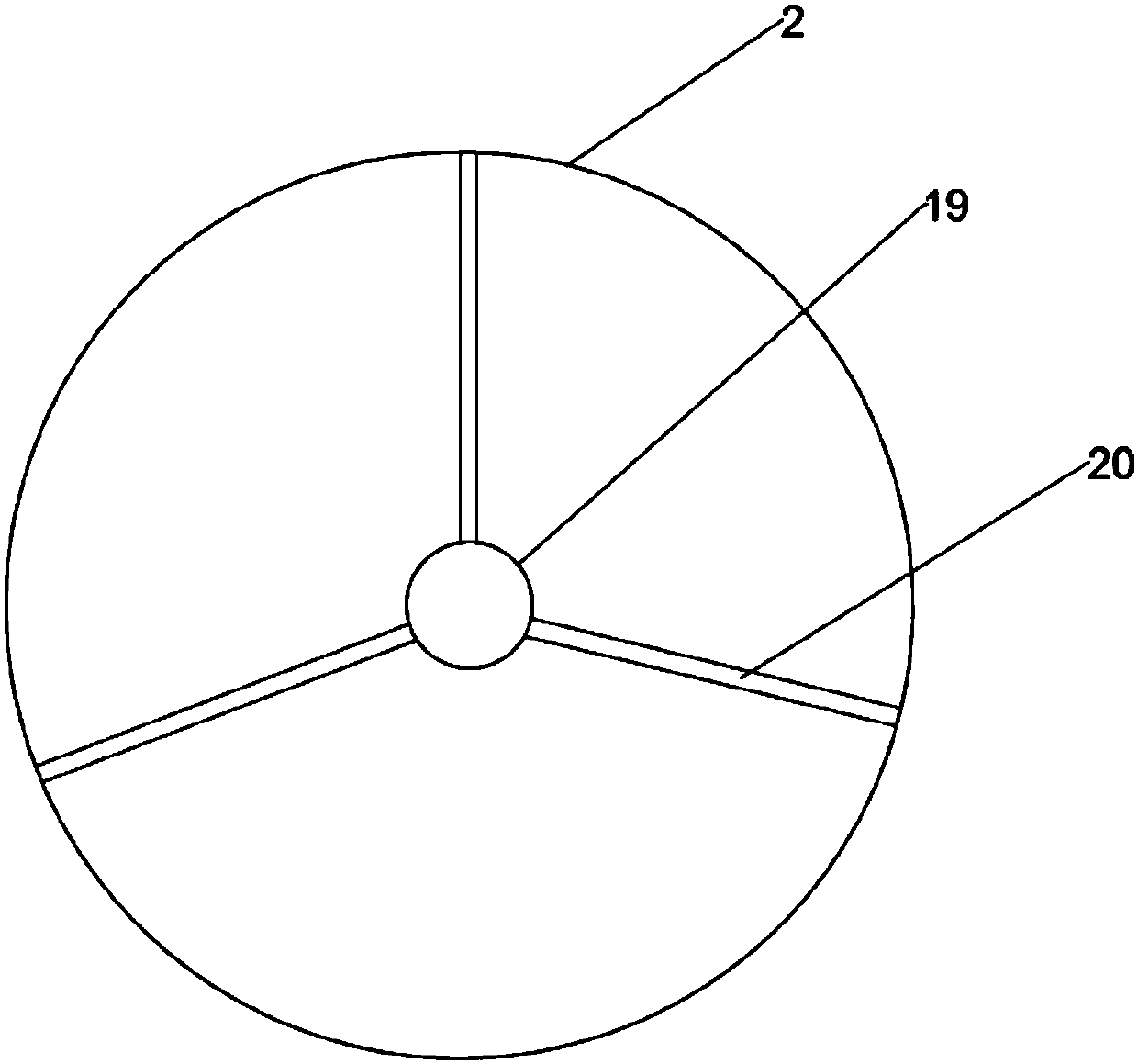

[0021] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides an efficient and environmentally friendly sludge separation device, including a housing support 1, a stirring dispersion tank 2, a secondary cyclone tank 3, and a tertiary separation tank 4. The stirring dispersion tank 2, the secondary cyclone Both the tank 3 and the tertiary separation tank 4 are installed in the housing support 1, and are characterized in that: the upper surface of the housing support 1 is provided with a feed hopper 5, and a frequency conversion motor 6 is provided above the feed hopper 5. The motor 6 is connected with a screw shaft 7, the screw shaft 7 is installed in the stirring and dispersing tank 2, the feed hopper 5 is connected to the upper end of the stirring and dispersing tank 2, and the bottom of the stirring and dispersing tank 2 is connected to the second through the pipe A8. The secondary swirl groove 3 is connected, a hydrocyclone 9 is in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap