Heating water heater for boiler

A heating water and heater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem that heating water cannot be fully heated, and achieve stable heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, configurations of specific embodiments of the present invention will be described with reference to the accompanying drawings.

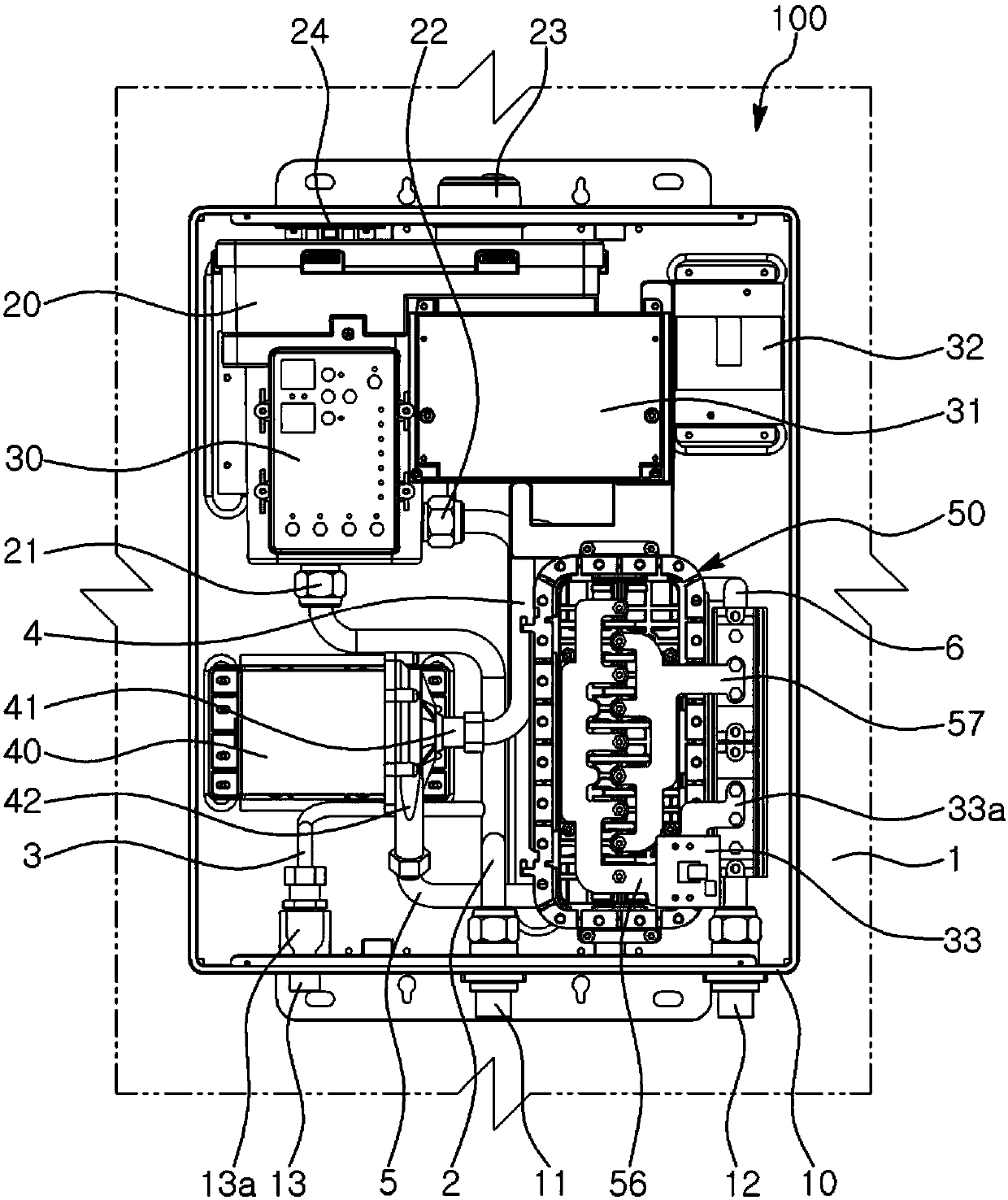

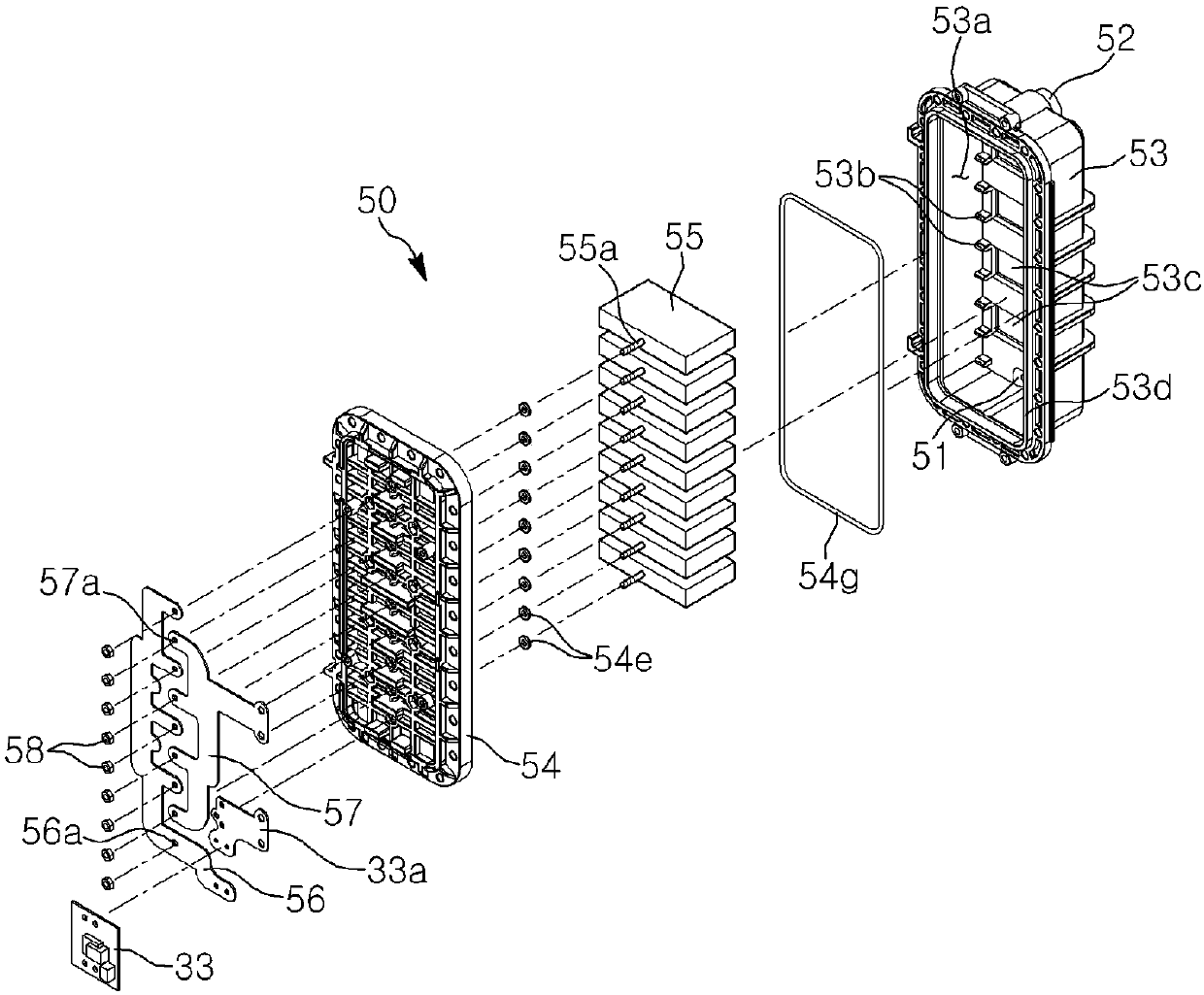

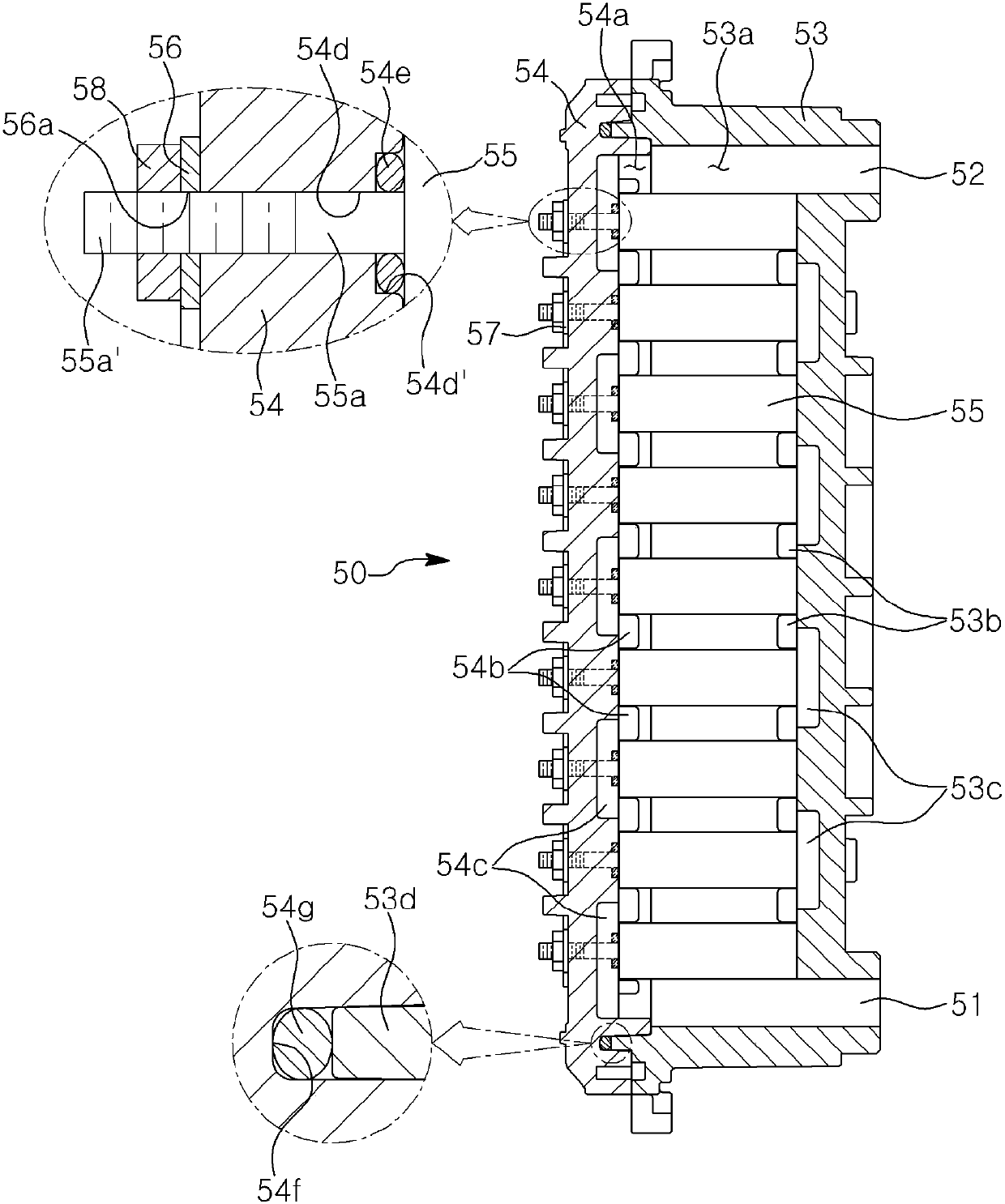

[0047] Such as Figure 1 to Figure 8 As shown, the boiler 100 provided with the heating water heater 50 according to the embodiment of the present invention is arranged on the wall 1 in the shape of a square barrel, including the boiler box 10 . The boiler box has: a first heating water inlet 11 provided on the lower surface of the outside, through which heating water circulated for heating flows in; and a first heating water outlet 12 through which the heating water is discharged.

[0048] In addition, the boiler 100 is provided with a water tank 20 on the upper side inside the boiler box 10 . The water tank 20 has a second heating water inlet 21 connected to the first heating water inlet 11 via the first moving pipe 2 , and a second heating water outlet 22 .

[0049] Here, the water tank 20 is provided with a cover 23 exposed to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap