Low-odor polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of low-odor polypropylene composite material and its preparation, and achieves the effects of good market prospect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

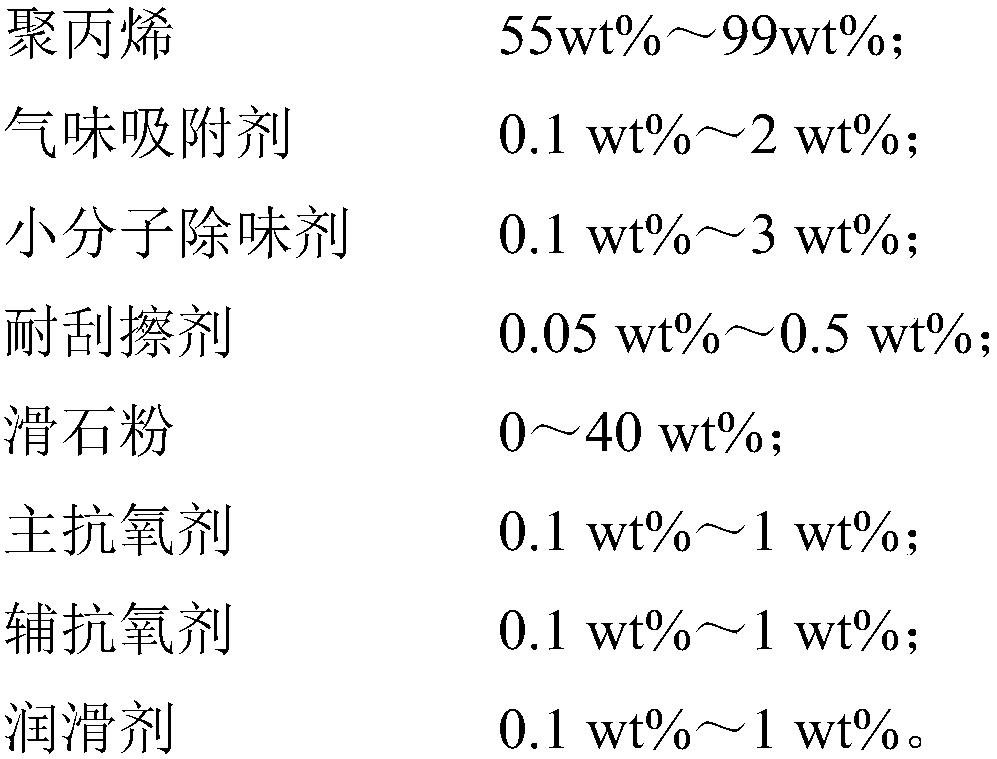

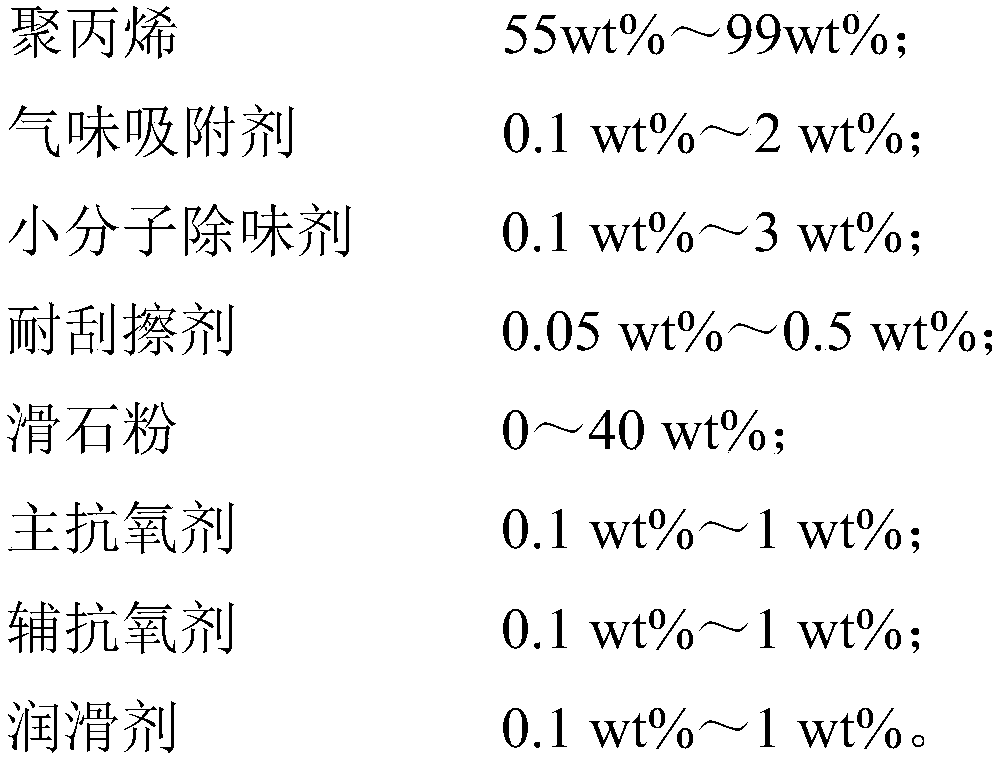

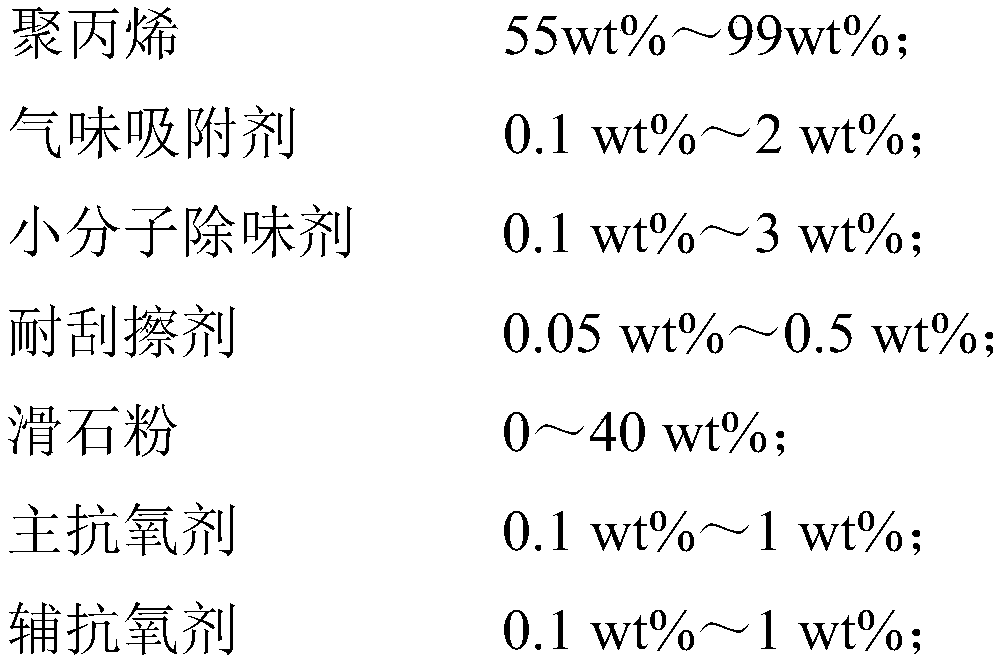

Method used

Image

Examples

Embodiment 1

[0038] (1) By weight percentage, accurately weigh 79wt% of 1215C, 18wt% of talcum powder BHS-818A, 1wt% of molecular sieve, 1wt% of jellyfish particles LDV 1040, 0.3wt% of erucamide, 0.2wt% of Antioxidant 1010, 0.2wt% antioxidant 168, 0.3% TAF;

[0039] (2) Put the above materials into a high-speed mixer and dry mix for 1-4 minutes, then put the mixed materials into a twin-screw extruder, melt and extrude through the twin-screw extruder, cool, dry, and pelletize to obtain the finished product.

Embodiment 2

[0041] (1) By weight percentage, accurately weigh 78wt% of 1215C, 18wt% of talcum powder BHS-818A, 1wt% of molecular sieve, 2wt% of jellyfish particles LDV 1040, 0.3wt% of erucamide, 0.2wt% of Antioxidant 1010, 0.2wt% antioxidant 168 and 0.3% TAF;

[0042](2) Put the above materials into a high-speed mixer and dry mix for 1-4 minutes, then put the mixed materials into a twin-screw extruder, melt and extrude through the twin-screw extruder, cool, dry, and pelletize to obtain the finished product.

Embodiment 3

[0044] (1) By weight percentage, accurately weigh 78wt% of 1215C, 18wt% of talcum powder BHS-818A, 2wt% of molecular sieves, 1wt% of jellyfish particles LDV 1040, 0.3wt% of erucamide, 0.2wt% of Antioxidant 1010, 0.2wt% antioxidant 168 and 0.3% TAF;

[0045] (2) Put the above materials into a high-speed mixer and dry mix for 1-4 minutes, then put the mixed materials into a twin-screw extruder, melt and extrude through the twin-screw extruder, cool, dry, and pelletize to obtain the finished product.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap