Automatic circuit board film pasting machine

A technology for circuit boards and laminating machines, which is applied in the secondary processing of printed circuits, coating non-metallic protective layers, etc. The effect of improving production efficiency and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

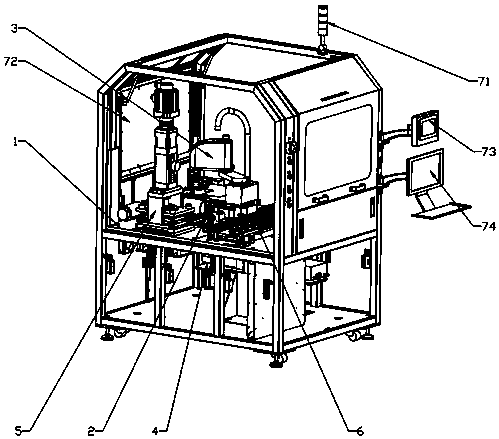

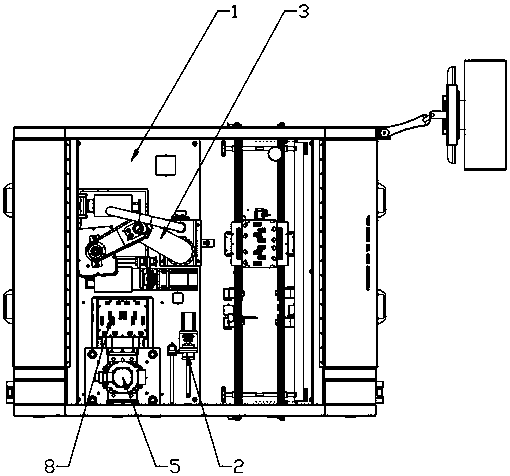

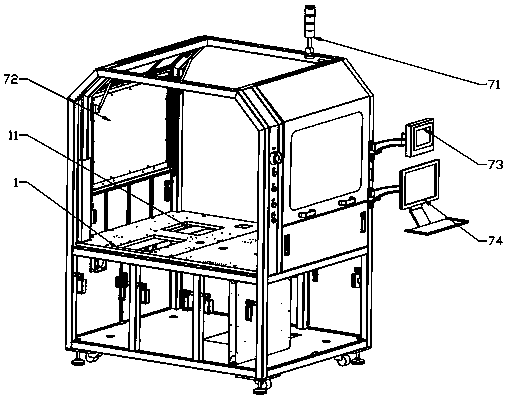

[0027] Such as Figure 1 to Figure 6 As shown, the specific embodiment of the present invention is: the present invention includes a main body frame 7, the middle part of the main body frame 7 is provided with a mounting plate 1 transversely, and the mounting plate 1 is fitted with a glue feeding and tearing device 2, used to transport and tear off the adhesive tape; the adsorption manipulator 3 is used to absorb the torn adhesive tape; the laser cutting machine 4 is located below the adsorption manipulator 3 and is used to cut the adhesive tape; Glue feeding and cutting module 5, used to transport and cut unadhesive tape; and circuit board conveying device 6, used to convey circuit boards; After pasting, attach it to the circuit board on the circuit board conveying device 6 . In the present invention, the glue feeding and tearing device 2 provides the glued tape, and the adsorption manipulator 3 grabs the glued tape and cooperates with the laser cutting machine 4 to complete th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap