Modified self-adhesive EVA chip and wall repairing tape, and production methods thereof

A self-adhesive and modified technology, applied in chemical instruments and methods, flat products, lamination, etc., can solve the problems of unresistable extension, construction time affecting construction progress, etc., to prevent deformation and performance degradation, and low overall production cost , the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

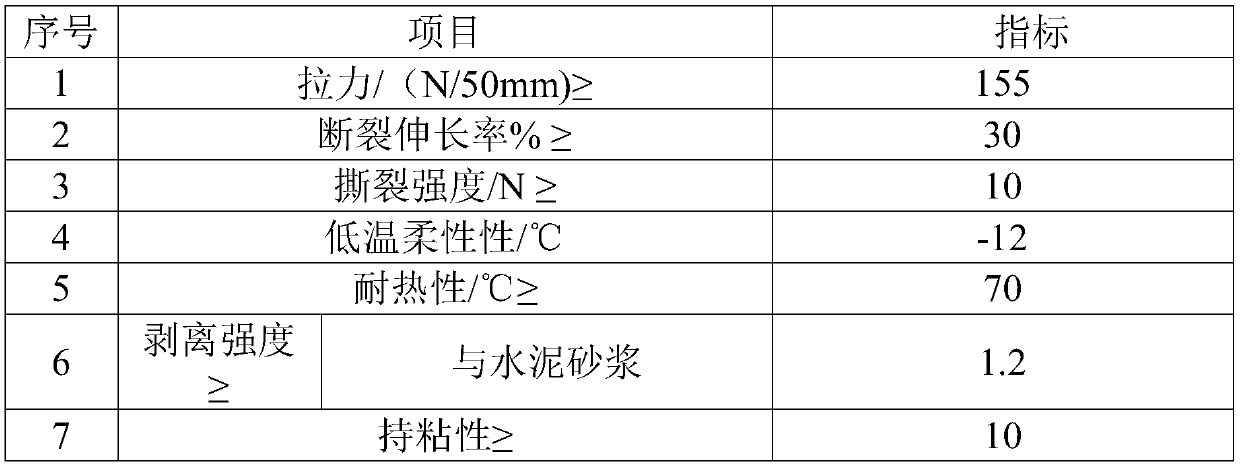

Embodiment 1

[0024] The modified self-adhesive EVA film is made of raw materials containing the following parts by weight: EVA resin: 100 parts, synthetic rubber (SIS): 6 parts, tackifier: 13 parts, petroleum resin: 5 parts, terpene resin T120: 8 parts, coupling agent: 5 parts

[0025] A modified self-adhesive EVA wall repair tape, the material includes a three-layer structure: from top to bottom: non-woven fabric, modified self-adhesive EVA film and isolation layer; the width of the product is 300mm;

[0026] The modified self-adhesive EVA film is prepared through a polymer material molding process.

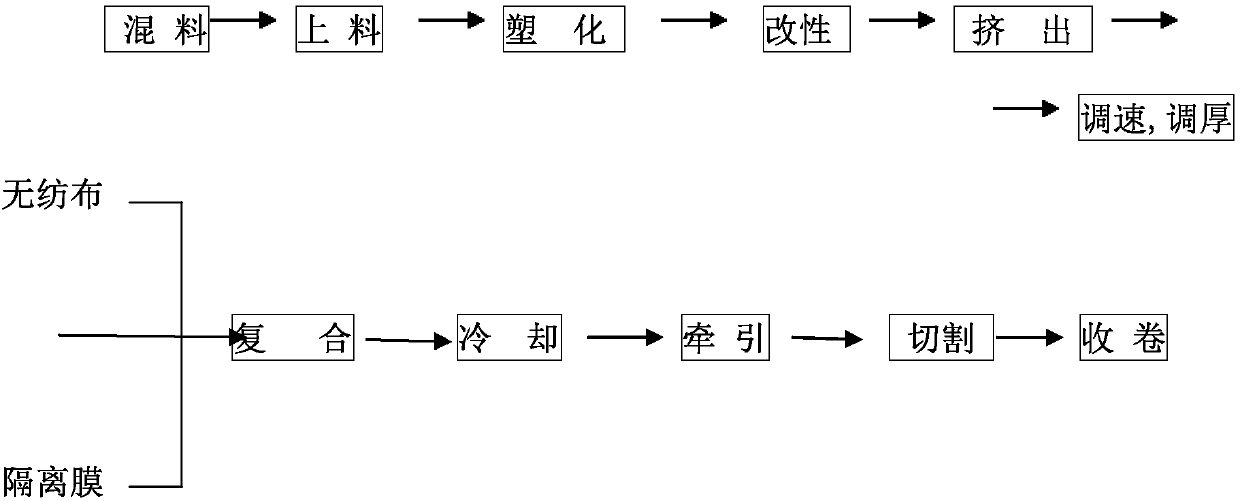

[0027] A preparation method of a modified self-adhesive EVA wall repair tape comprises the following steps:

[0028] (1) EVA resin, synthetic rubber (SIS), tackifier, petroleum resin, terpene resin, and coupling agent are dropped into the mixer at room temperature and pre-mixed to obtain a preliminary mixed base material;

[0029] (2) the primary mixed base material that described step (1) ob

Embodiment 2

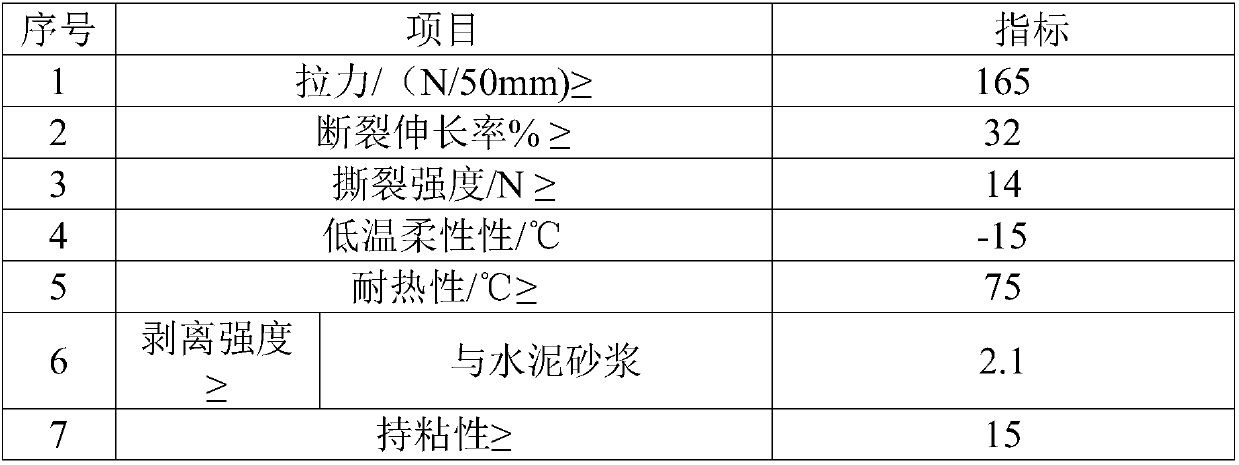

[0038] The modified self-adhesive EVA film is made of raw materials containing the following parts by weight: EVA resin: 100 parts, synthetic rubber (SIS): 10 parts, tackifier: 15 parts, petroleum resin: 8 parts, terpene resin T120: 9 parts, coupling agent: 5 parts

[0039] A modified self-adhesive EVA wall repair tape, the material includes a three-layer structure: from top to bottom: non-woven fabric, modified self-adhesive EVA film and isolation layer; the width of the product is 300mm;

[0040] The modified self-adhesive EVA film is prepared through a polymer material molding process.

[0041] A preparation method of a modified self-adhesive EVA wall repair tape, the method comprises the steps of:

[0042] A preparation method of a modified self-adhesive EVA wall repair tape comprises the following steps:

[0043] (1) EVA resin, synthetic rubber (SIS), tackifier, petroleum resin, terpene resin, and coupling agent are dropped into the mixer at room temperature and pre-mixed

Embodiment 3

[0053]The modified self-adhesive EVA film is made of raw materials containing the following parts by weight: EVA resin: 100 parts, synthetic rubber (SIS): 12 parts, tackifier: 18 parts, petroleum resin: 10 parts, terpene resin T120: 11 parts, coupling agent: 5 parts

[0054] A modified self-adhesive EVA wall repair tape, the material includes a three-layer structure: from top to bottom: non-woven fabric, modified self-adhesive EVA film and isolation layer; the width of the product is 300mm;

[0055] The modified self-adhesive EVA film is prepared through a polymer material molding process.

[0056] A preparation method of a modified self-adhesive EVA wall repair tape, the method comprises the steps of:

[0057] A preparation method of a modified self-adhesive EVA wall repair tape comprises the following steps:

[0058] (1) EVA resin, synthetic rubber (SIS), tackifier, petroleum resin, terpene resin, and coupling agent are dropped into the mixer at room temperature and pre-mixed

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap