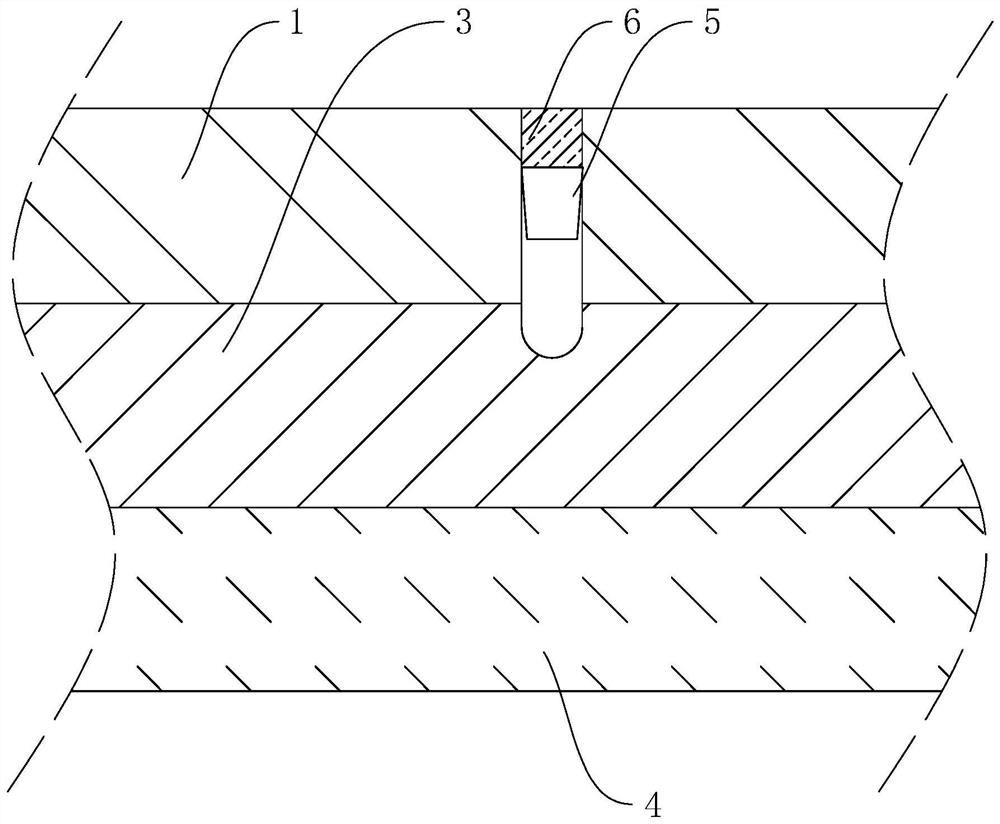

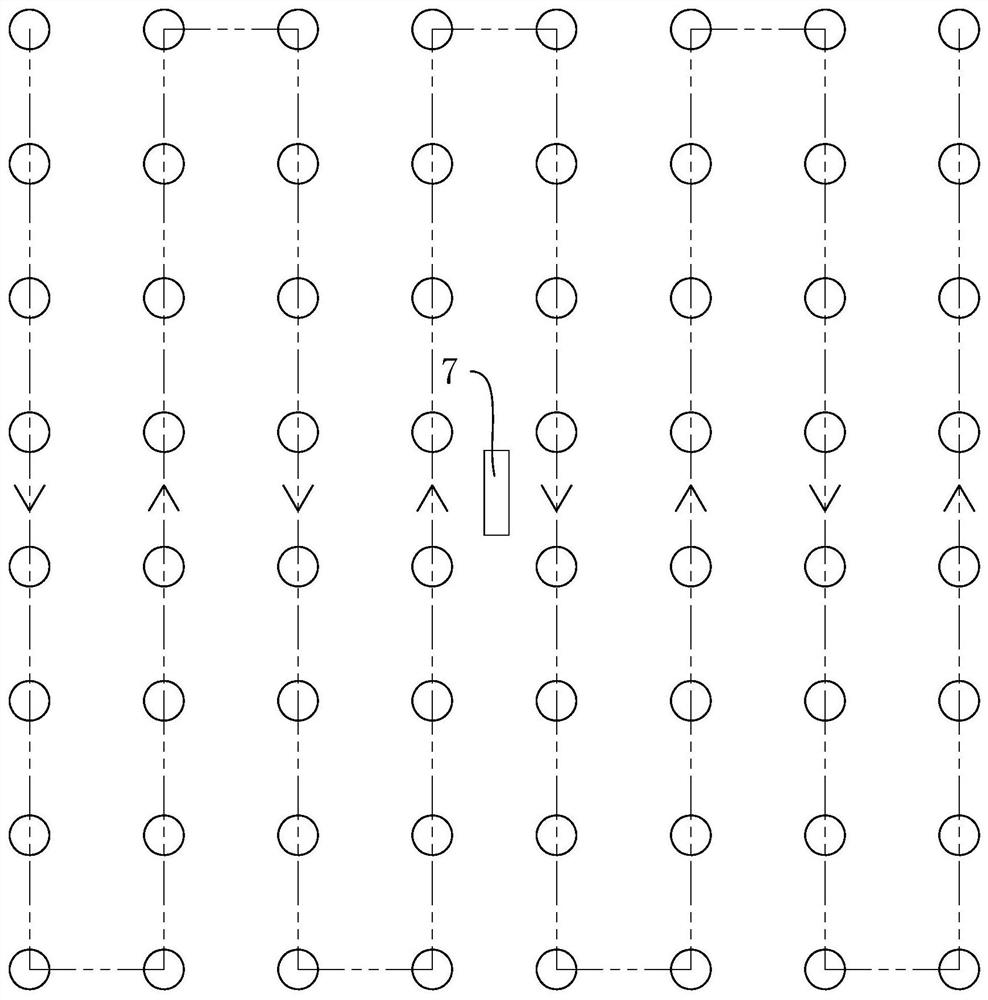

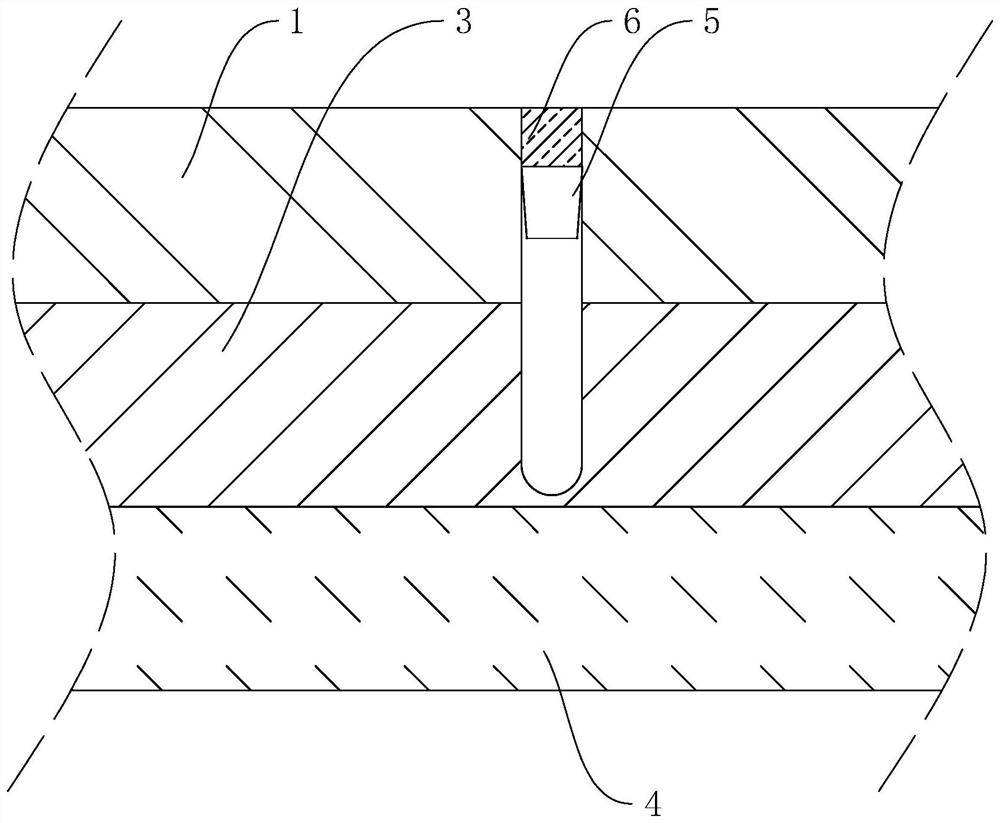

Regenerated waterproof layer construction method

A construction method and waterproof layer technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of low repair efficiency of waterproof layer, large amount of engineering, complicated operation, etc., so as to improve the waterproof effect and mechanical strength, and prolong the service life The effect of high life and rebuilding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0072] A waterproof material, the components and their corresponding weights are shown in Table 1, and are prepared through the following steps:

[0073] S1, mix 35kg petroleum resin, 6kg acrylic resin and 58kg deionized water at a rotating speed of 3500r / min to obtain the resin component;

[0074] S2, take 0.05kg of hardening accelerator and mix it with the same amount of deionized water, add 10kg of the resin component obtained in S1 after mixing, and mix at a speed of 800r / min to obtain a waterproof material.

[0075] In this embodiment, ultra-fine cement is used as the hardening accelerator.

preparation example 2

[0077] A kind of waterproof material, except that the usage amount of petroleum resin, acrylic resin and deionized water in step S1 is different from that of Preparation Example 1, other conditions are the same. In this embodiment, the usage amount of petroleum resin is 40kg, and the usage amount of acrylic resin is 8kg , The amount of deionized water used is 52kg.

preparation example 3

[0079] A kind of waterproof material, except that the usage amount of petroleum resin, acrylic resin and deionized water in step S1 is different from that of Preparation Example 1, other conditions are the same. In this embodiment, the usage amount of petroleum resin is 45kg, and the usage amount of acrylic resin is 10kg , The amount of deionized water used is 45kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap