High-performance axial-flow fan for extractor hood

A technology of range hoods and axial flow fans, which is applied to parts of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., and can solve problems such as wind resistance of wind rotors, influence of wind rotor speed, and reduction of wind pressure , to achieve the effect of improving separation, improving fluid power efficiency and reducing motion wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

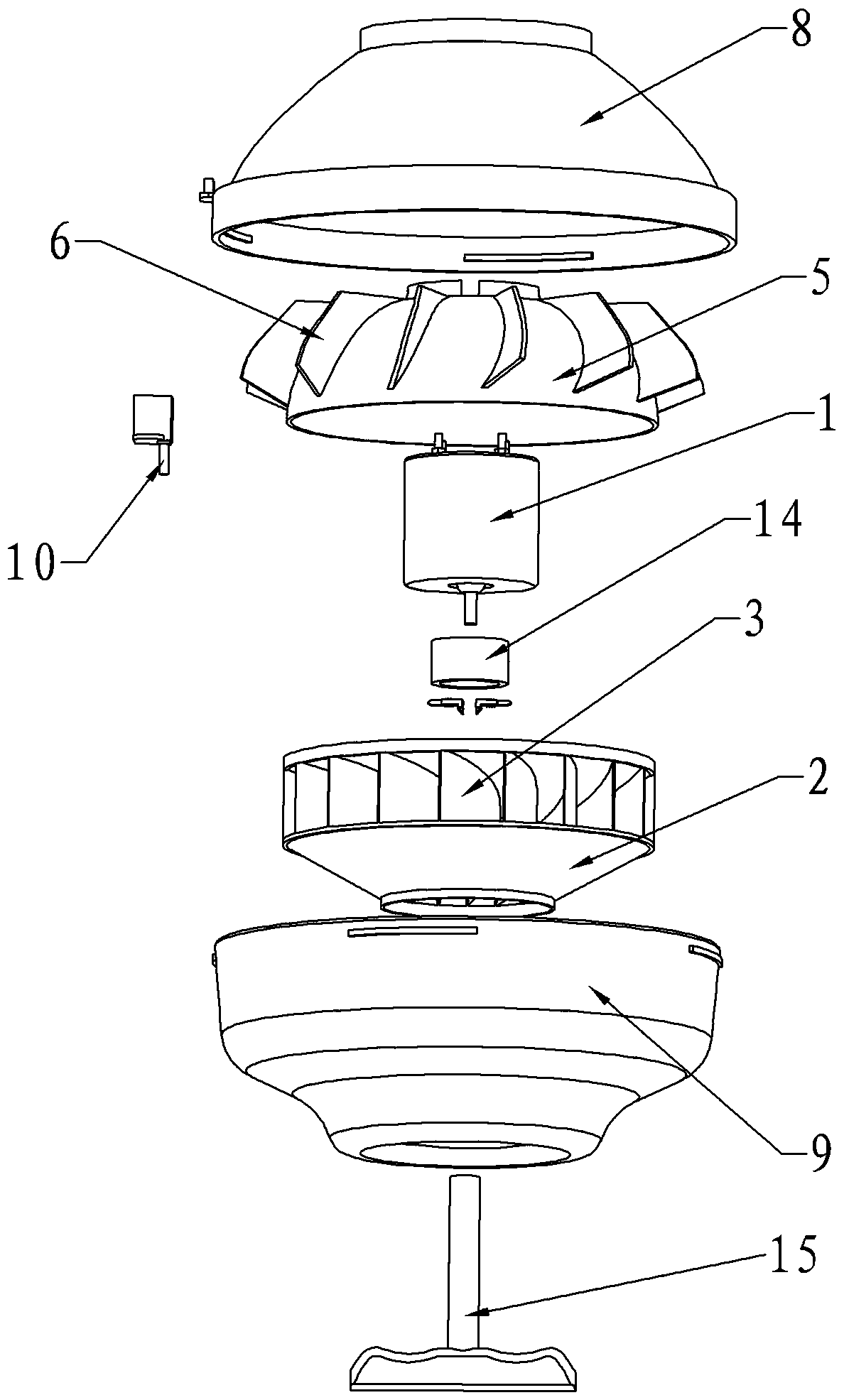

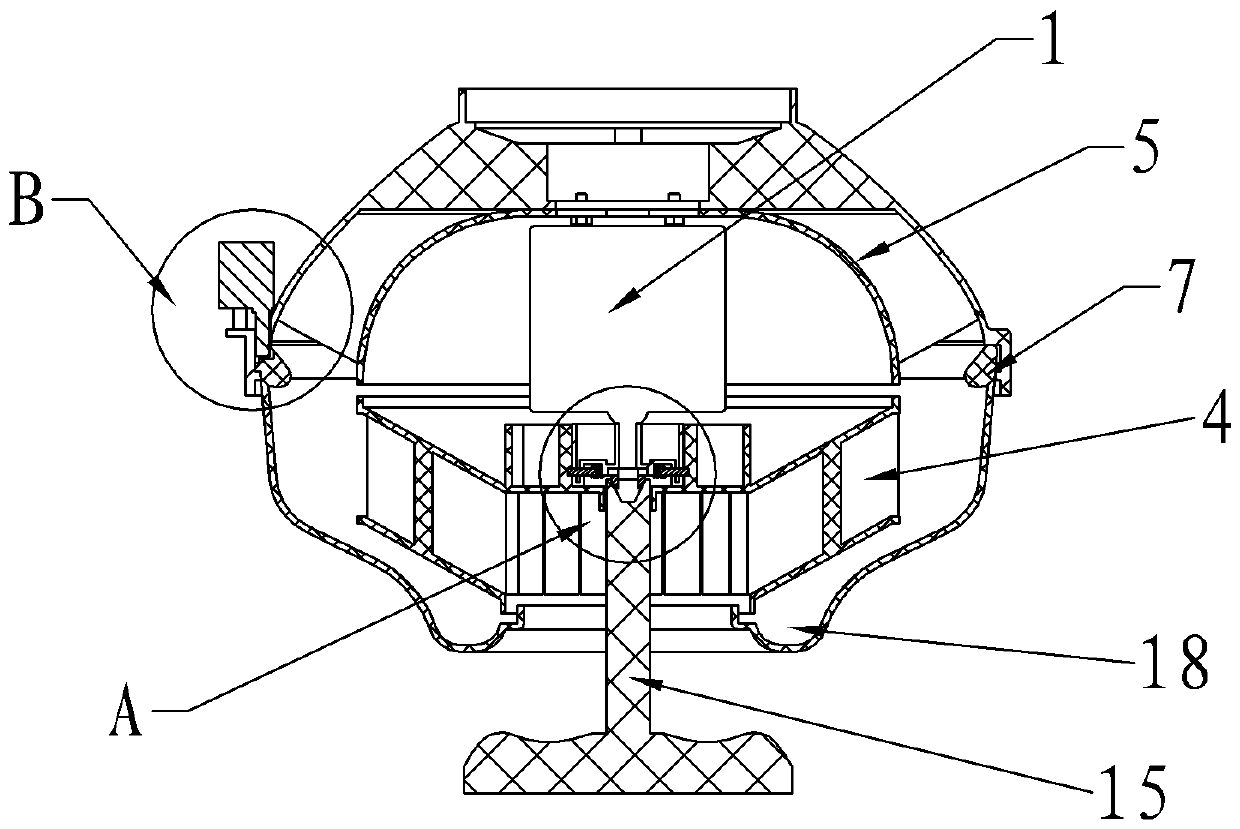

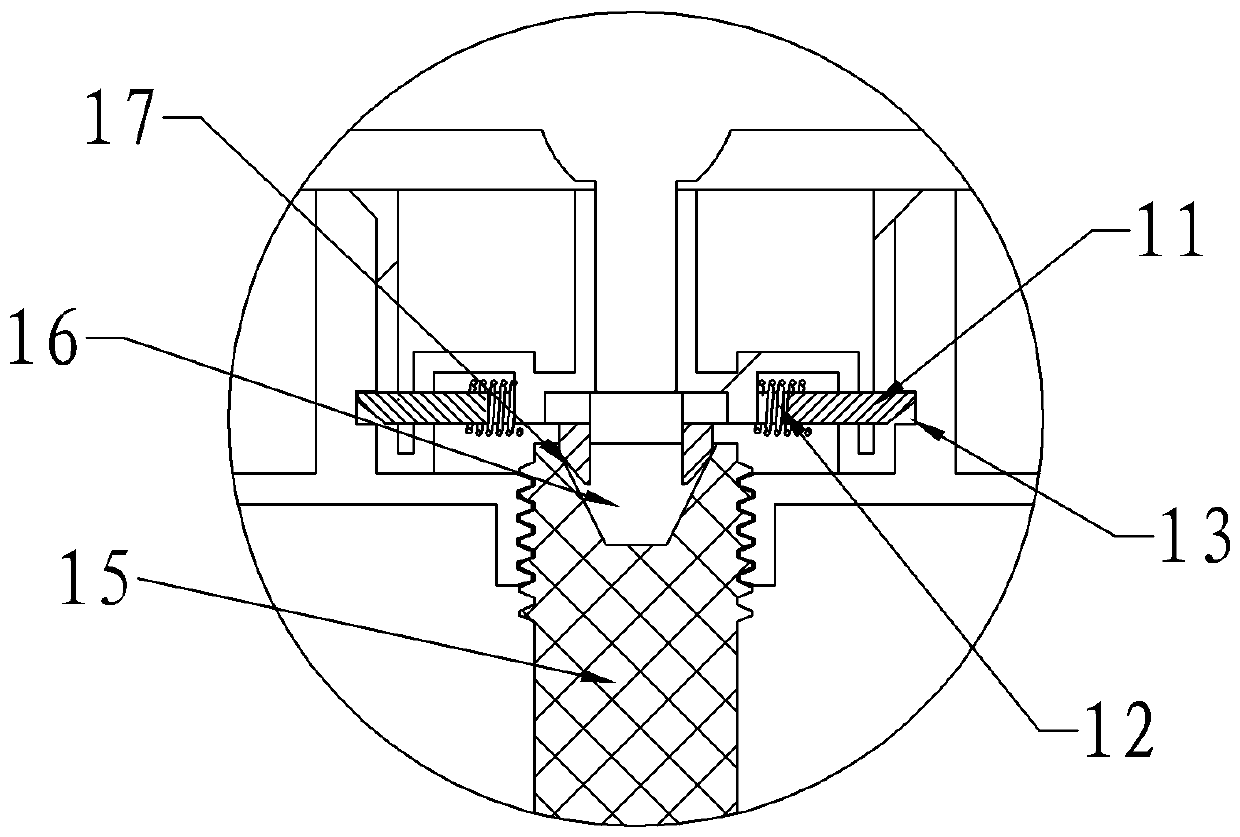

[0019] Such as figure 1 and figure 2 As shown, a high-performance axial flow fan for a range hood includes a casing and a centrifugal wind wheel 2 installed in the casing and driven by a motor 1. The centrifugal wind wheel 2 is at least composed of radially distributed arc-shaped blades 3, adjacent to An air channel 4 is formed between the arc-shaped blades 3, and the air channel 4 is inclined toward the air outlet of the fan along the direction from inside to outside. The inclined air duct 4 is designed so that the high-pressure wind generated by the centrifugal wind wheel 2 rebounds to the exhaust outlet of the fan after hitting the inner wall of the casing, and will not enter the centrifugal fan again. This design can greatly reduce the wind of the centrifugal wind wheel 2. The turbulence between the outlet of channel 4 and the inner wall of the shell improves the overall fluid dynamic efficiency of the fan, thereby reducing the movement wind resistance of the centrifugal fa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap