Industrial automatic crusher

An industrial automation and pulverizer technology, applied in the field of industrial production, can solve the problems of reducing production efficiency and inconvenient continuous operation, and achieve the effect of improving production efficiency and protecting the production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

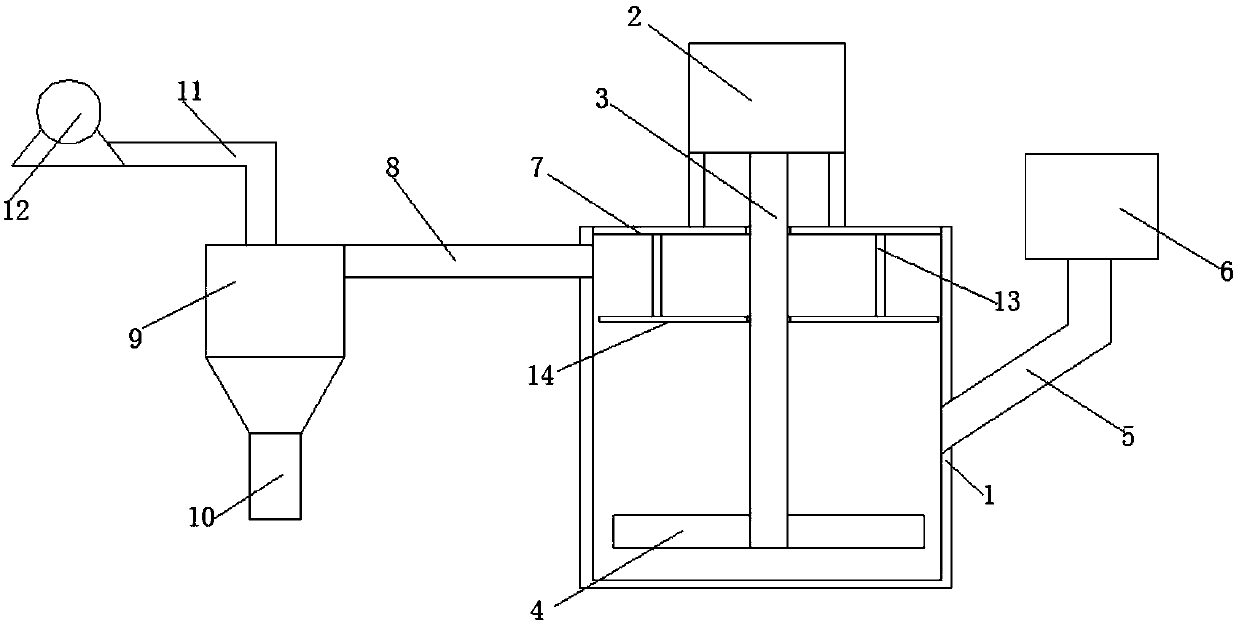

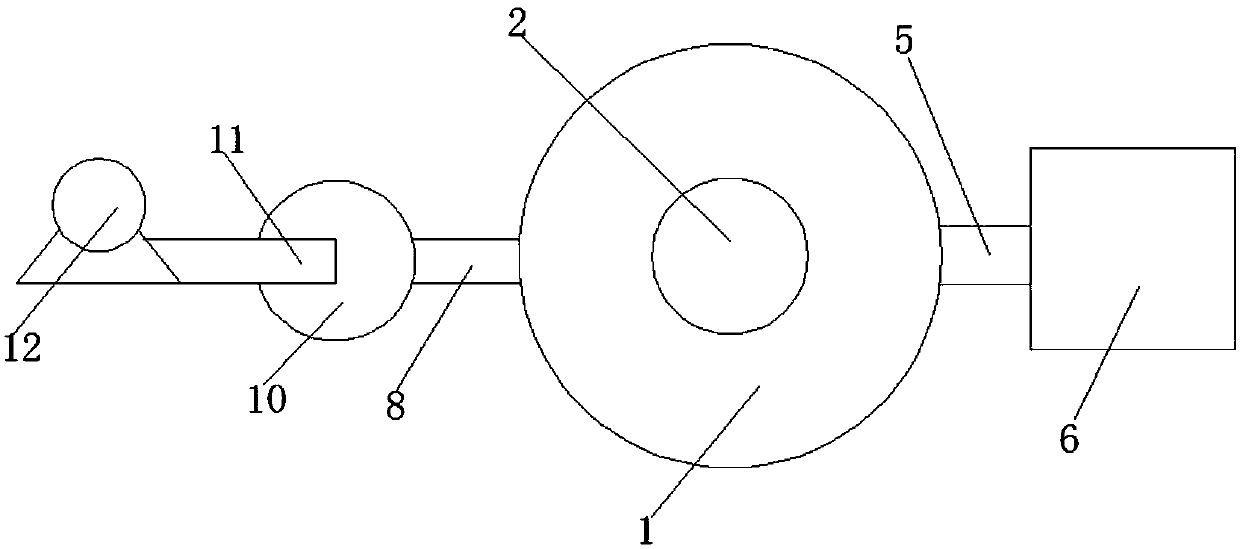

[0018] refer to Figure 1-2 , an industrial automatic pulverizer, including a box body 1, a cover plate 7 is installed on the upper end of the box body 1 through a card slot, a motor 2 is installed on the upper end of the cover plate 7 through a support rod, and the output end of the motor 2 is connected to the The rotating shafts 3 are connected, the lower end of the rotating shaft 3 is welded with a blade 4, and the lower end of the cover plate 7 is welded with a bracket 13, the lower end of the bracket 13 is equipped with a filter screen 14 through screws, and the upper end of the side wall of the box body 1 is welded with a discharge Pipe 8, the other end of the dis

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap