Coat hanger rough planer

A technology of rough planer and hanger, which is applied in forming/shaping machine, special forming/shaping machine, wood processing equipment, etc., which can solve the problem of poor cooperation between hanger and planer, low processing precision of hanger curved surface, and inconsistent shape of curved surface and other problems, to achieve the effect of good planing and milling effect, compact structure, and easy processing and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Embodiment one

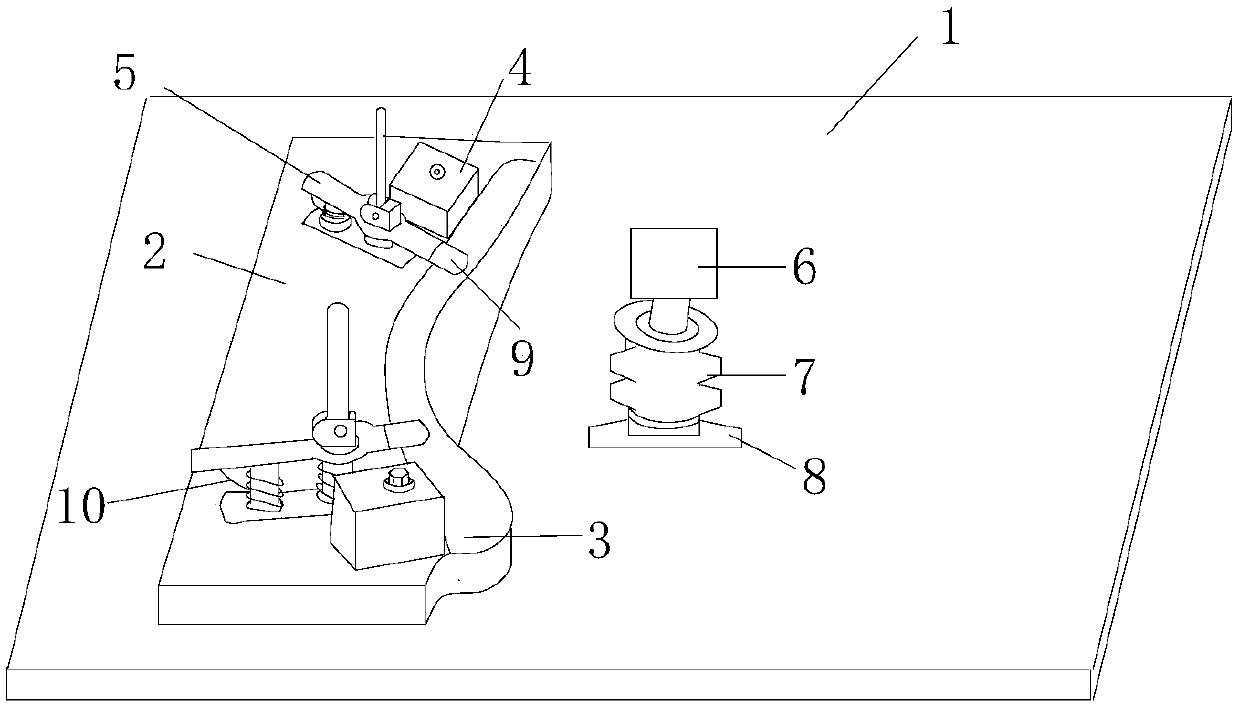

[0024] see Figure 1-2 , a clothes hanger rough planer, comprising a rough planer working platform 1, the rough planer working platform 1 is provided with an edge planer for beveling the clothes hanger, and the rough planer working platform 1 is also provided with a device capable of The profiling board 2 that moves on the surface of the planer working platform 1 is provided with a hanger template 3 on the profiling board 2, one end of the hanger template 3 is aligned with one end of the profiling board 2, and the two sides of the clothes hanger template 3 are respectively provided with The positioning blocks 4 are provided with clamps 5 for clamping the clothes hanger between the positioning blocks 4 . During specific design, the contacting surface of the rough planer working platform 1 and the profiling board 2 is set to a smooth surface, which is convenient for the profiling board 2 to move along the rough planer working platform 1 for planing.

[002

Example Embodiment

[0030] Embodiment two

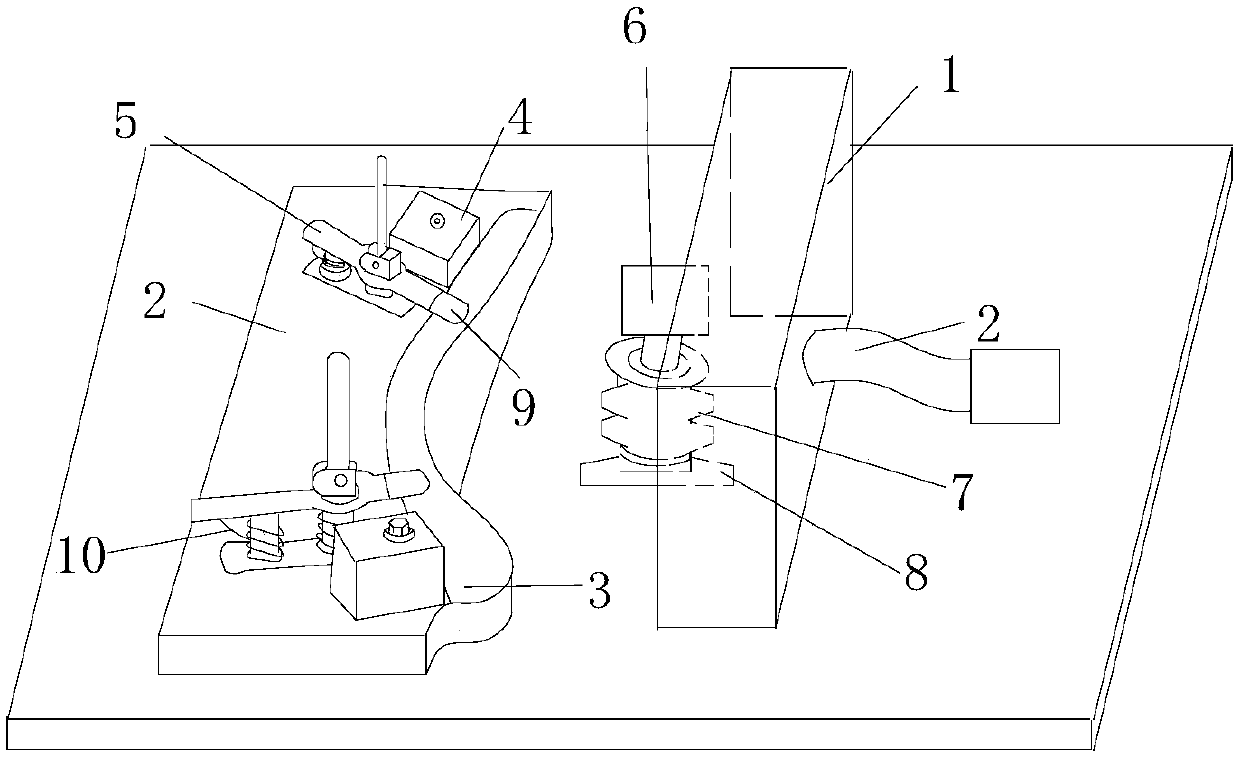

[0031] In this embodiment, it is basically the same as Embodiment 1, and the difference is that the clothes hanger rough planer also includes a dust suction device, please refer to image 3 , the dust collection device comprises a dust collection cover 11, a suction pipe and a suction fan 13; the dust collection cover 11 is connected with the dust collection fan 13 through the suction pipe; Located outside the edge planer, the dust suction device is used to suck out the fine slag of imitation milling wood chips to ensure the smoothness of planing.

[0032] The working principle and method of use of a wooden clothes hanger fine planer of the present invention are as follows:

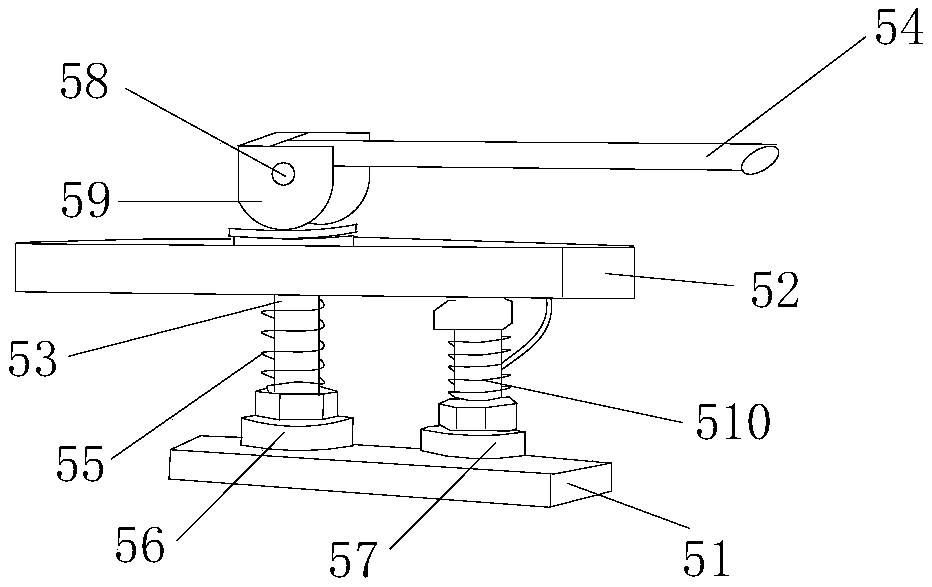

[0033]Clothes hanger semi-finished product is placed in the clothes hanger template 3 on the profiling board 2, and when turning the handle 54 to make the arc portion of the semicircular rotating block 59 contact with the pressing plate, the clamping plate 52 can be pressed down, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap